Brooks, Model 5851e – Brooks Instrument 5851E User Manual

Page 27

3-7

Brooks

®

Model 5851E

Section 3 Operation

Installation and Operation Manual

X-TMF-5851E-MFC-eng

Part Number: 541B104AAG

November, 2008

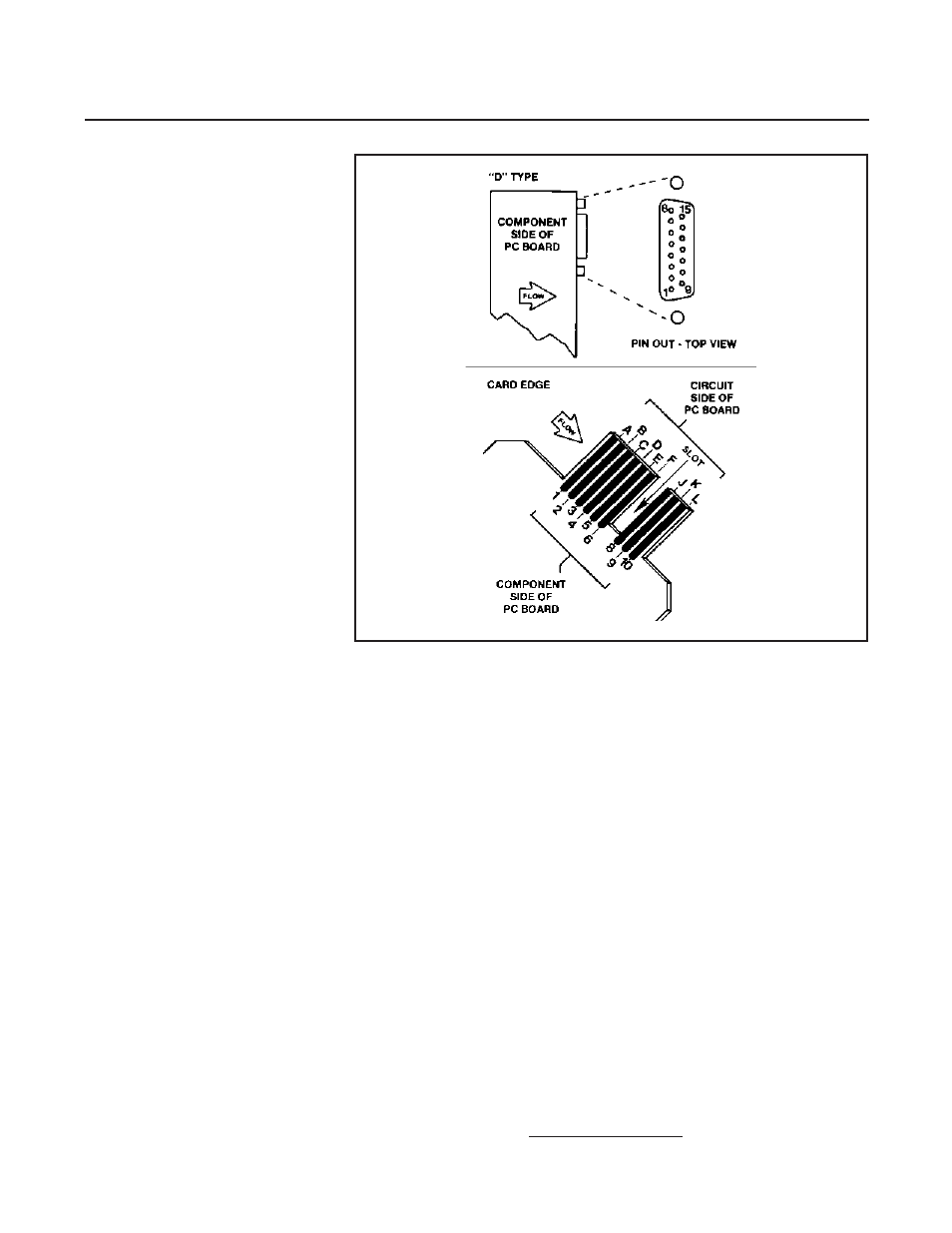

Figure 3-5 Model 5851E Calibration Connections

c. Connect the DVM positive lead to the 0-5 V signal output (Terminal 3

Card Edge, Pin 2 D-Connector) and the negative lead to signal com-

mon (TP4). Adjust the zero potentiometer for an output of 0 mV ±2 mV.

d. Apply pressure to the system and insure that the zero signal repeats

within 2 mV of the voltage set in Step c above. If the zero does not

repeat, check for leakage.

Note: Controllers supplied with all-metal valve seats do not provide tight

shut-off. A 0 to 3% leak through is typical. For metal seat controllers

close a downstream shut-off valve and observe the zero signal.

e. Set the command potentiometer (connected to Terminals A, B and 10

of the Card Edge connector and Terminals 8, 1 and 11 of the D-Con-

nector for 100% of flow (5.000 V). Connect the DVM positive lead to

TP2 (linearity voltage) and the negative lead to TP4 (signal common).

Adjust the linearity potentiometer for an output of 0.0 V (zero Volts).

f. Connect the DVM positive lead to TP1 (-100x sensor voltage) and the

negative lead to TP4 (circuit common). The command potentiometer

should still be set at 100% flow (5.000 V). Measure the flow rate using

suitable volumetric calibration equipment. To adjust the controller to the

proper full scale flow, calculate a new TP1 voltage using the following

equation.

measured TP1 voltage

New TP1 voltage=

x desired flow rate

measured flow rate