Ironwood Electronics GHz Socket Specifications User Manual

Ghz socket specifications

File Name: GHS.doc

Rev: B

Date: 5/28/02

By: Ila Pal

Tel: (800) 404-0204

www.ironwoodelectronics.com

GHz Socket Specifications

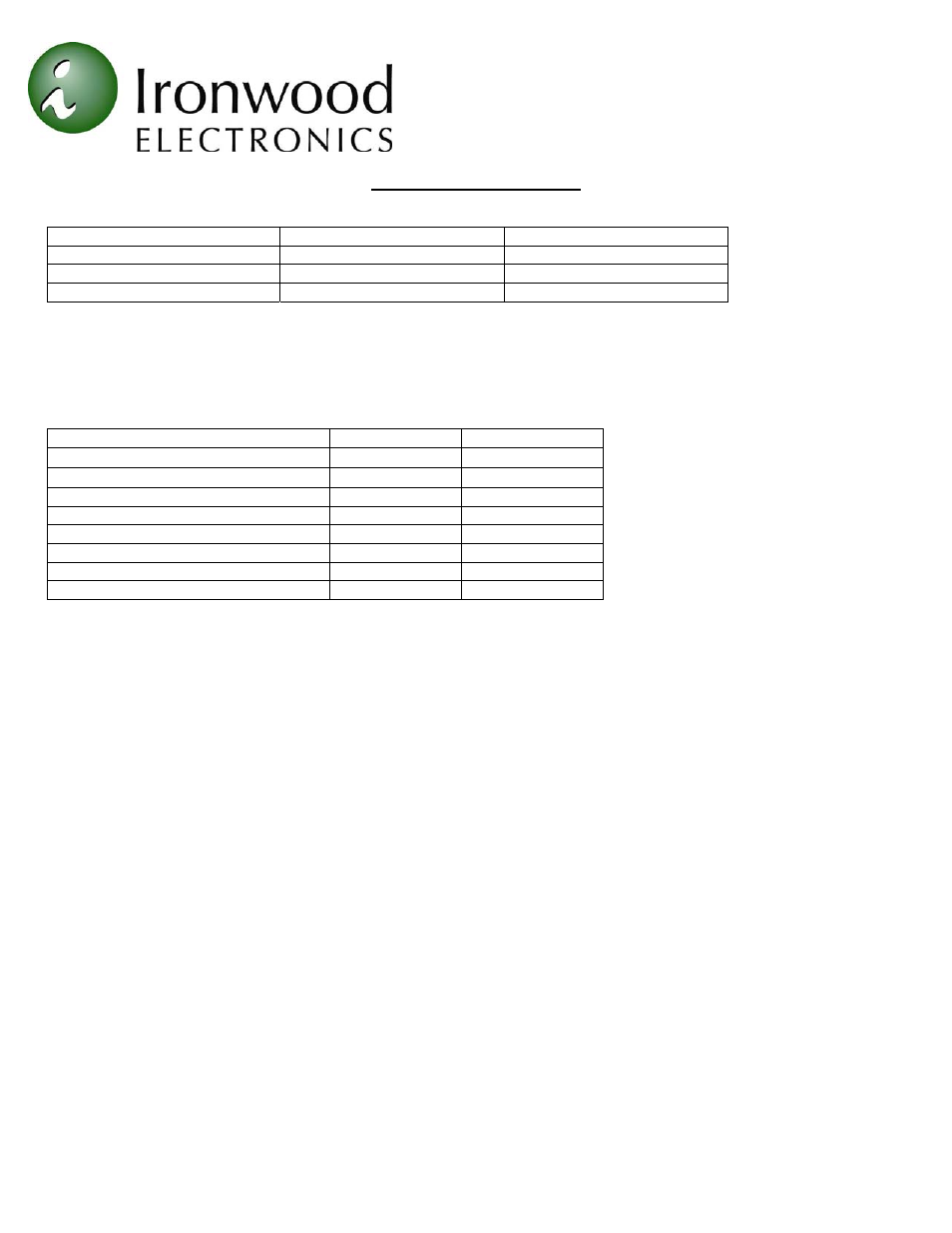

Mechanical Specifications

Individual contact force:

BGA Package

Depth of penetration (mm)

Force per ball (grams)

Typical 1.27mm pitch BGA

i

0.1 20.4

Typical 1.0mm pitch BGA

ii

0.1 16

Typical 0.8mm pitch BGA

iii

0.1

8.1

Notes:

i

0.75mm Nominal solder ball diameter was used in the calculation.

ii

0.6mm Nominal solder ball diameter was used in the calculation.

iii

0.4mm Nominal solder ball diameter was used in the calculation.

Conductive elastomer life: 1700 cycles.

Electrical Specifications

0.5mm Thick

0.75mm Thick

Contact resistance:

23m

Ω

1

25m

Ω

1

Insulation resistance:

1000M

Ω

2

1000M

Ω

2

Self Inductance:

0.15nH

3

0.28nH

3

Bandwidth: 10.0GHz

6.5GHz

4

Insertion loss:

1dB@10GHz

4

Mutual Capacitance (at PCB):

0.010pF

5

0.011pF

5

Mutual Capacitance (at device):

0.015pF

5

0.015pF

5

Current carrying capacity:

50mA/wire

6

50mA/wire

6

Notes:

1

Maximum contact resistance with 0.2mm compression (contact resistance will decrease with increased compression). Measurements

were taken using 0.4mm square electrodes. The 0.75mm value is interpolated from a test of 0.5mm, 1mm, and 2.0mm elastomers.

2

The test used 0.5mm wide Au plated electrodes with a 0.5mm gap between them. 500VDC was used with a 1mm thick elastomer

compressed 0.35mm.

3

Measurements were taken with a flat gold plated electrode. The 0.75mm value is interpolated from a test of several elastomer

thicknesses ranging from 0.1mm to 2.0mm.

4

This is a conservative estimate based on 1mm thick elastomer test results with test probes spaced at 0.5mm.

5

Measurements were taken with test probes at 0.5mm pitch. The 0.75mm value is interpolated from a test of several elastomer

thicknesses ranging from 0.1mm to 2.0mm.

6

The wires are on a 0.1x0.1mm grid. Multiple wires make contact per solder ball based on its size and depth of penetration.

Operating Temperature

Continuous usage:

-35C to +85C

Compression

set:

150C

for

22hrs

Thickness change: -4.5%

Vibration

Standard: MIL-STD202,

METHOD

204,

CONDITION

A

No change in resistance and thickness

Humidity

Standard: MIL-STD202,

METHOD

106

Resistance

change:

26

m

Ω

Thickness

change:

-1%

Thermal shock

Standard: MIL-STD202,

METHOD

107,

CONDITION

A

Resistance

change:

-19

m

Ω

Thickness

change:

-1%

Temperature cycling

Standard: MIL-STD202,

METHOD

103,

CONDITION

A

Resistance

change:

15

m

Ω