Warning, Irculating, Ilters – Goodman Mfg VC8 User Manual

Page 21: Stalactic, Clyde’s, Or john crane, Propane gas installation (typ.), Ilters n

21

C

IRCULATING

A

IR

AND

F

ILTERS

P

ROPANE

G

AS

T

ANKS

AND

P

IPING

I

F

THE

GAS

FURNACE

IS

INSTALLED

IN

A

BASEMENT

,

AN

EXCAVATED

AREA

OR

CONFINED

SPACE

,

IT

IS

STRONGLY

RECOMMENDED

TO

CONTACT

A

PROPANE

SUPPLIER

TO

INSTALL

A

GAS

DETECTING

WARNING

DEVICE

IN

CASE

OF

A

GAS

LEAK

.

S

INCE

PROPANE

GAS

IS

HEAVIER

THAN

AIR

,

ANY

LEAKING

GAS

CAN

SETTLE

IN

ANY

LOW

AREAS

OR

CONFINED

SPACES

.

P

ROPANE

GAS

ODORANT

MAY

FADE

,

MAKING

THE

GAS

UNDETECTABLE

EXCEPT

WITH

A

WARNING

DEVICE

.

•

•

WARNING

A gas detecting warning system is the only reliable way to

detect a propane gas leak. Rust can reduce the level of odorant

in propane gas. Do not rely on your sense of smell. Contact a

local propane gas supplier about installing a gas detecting

warning system. If the presence of gas is suspected, follow

the instructions on Page 3 of this manual.

All propane gas equipment must conform to the safety stan-

dards of the National Board of Fire Underwriters, NBFU Manual

58.

For satisfactory operation, propane gas pressure must be 10

inch WC at the furnace manifold with all gas appliances in

operation. Maintaining proper gas pressure depends on three

main factors:

1. Vaporization rate, depending on temperature of the liquid,

and “wetted surface” area of the container or containers.

2. Proper pressure regulation. (Two-stage regulation is

recommended for both cost and efficiency).

3. Pressure drop in lines between regulators, and between

second stage regulator and the appliance. Pipe size will

depend on length of pipe run and total load of all

appliances.

Complete information regarding tank sizing for vaporization, rec-

ommended regulator settings, and pipe sizing is available from

most regulator manufacturers and propane gas suppliers.

Since propane gas will quickly dissolve white lead and most

standard commercial compounds, special pipe dope must be

used. Shellac-based compounds resistant to the actions of

liquefied petroleum gases such as Gasolac

®

, Stalactic

®

,

Clyde’s

®

or John Crane

®

are satisfactory.

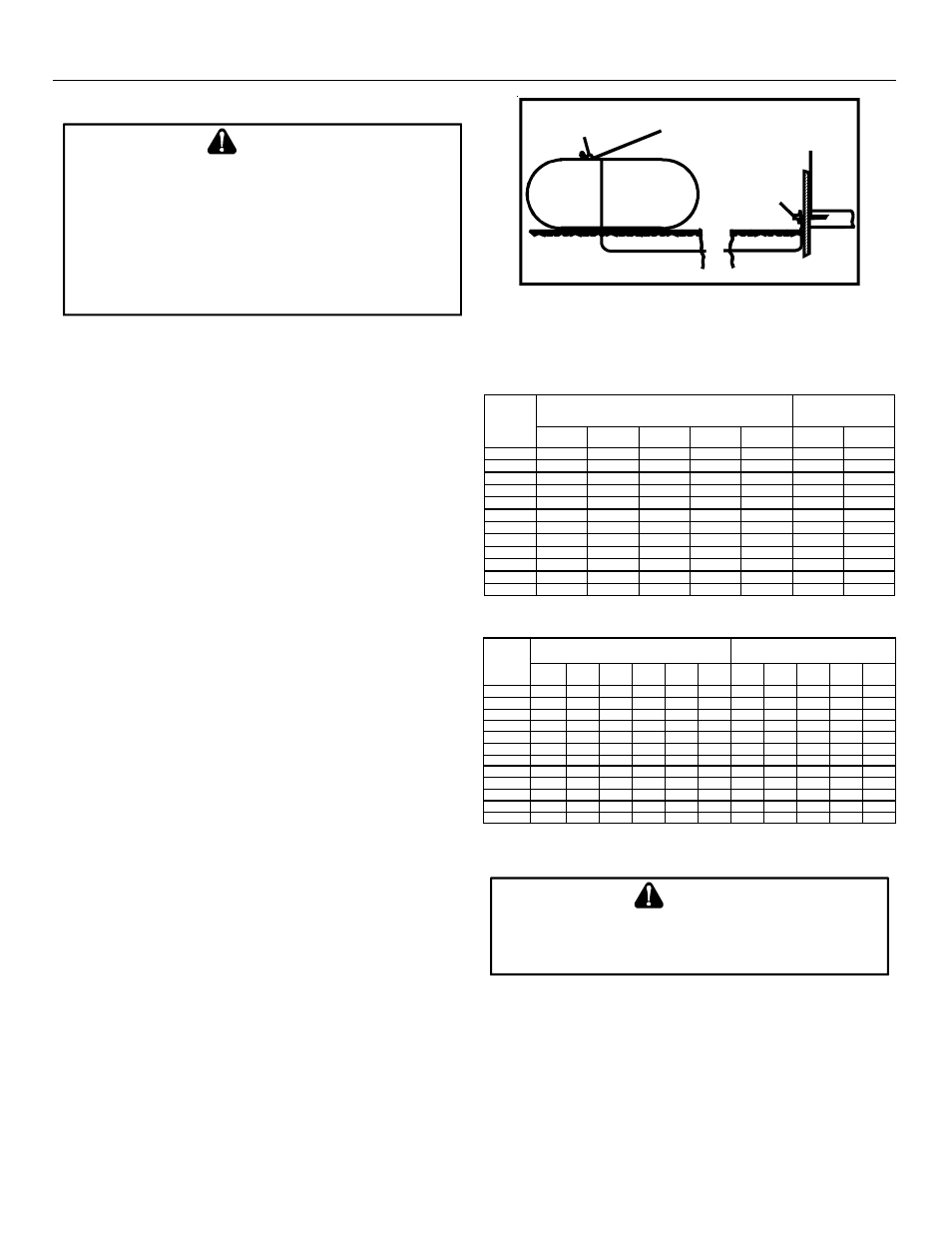

Refer to the following illustration for typical propane gas instal-

lations and piping.

200 PSIG

Maximum

5 to 15 PSIG

(20 PSIG Max.)

Continuous

11" W.C.

Second Stage

Regulator

First Stage

Regulator

Propane Gas Installation (Typ.)

P

ROPANE

G

AS

P

IPING

C

HARTS

3/8"

1/2"

5/8"

3/4"

7/8"

1/2"

3/4"

10

730

1,700

3,200

5,300

8,300

3,200

7,500

20

500

1,100

2,200

3,700

5,800

2,200

4,200

30

400

920

2,000

2,900

4,700

1,800

4,000

40

370

850

1,700

2,700

4,100

1,600

3,700

50

330

770

1,500

2,400

3,700

1,500

3,400

60

300

700

1,300

2,200

3,300

1,300

310

80

260

610

1,200

1,900

2,900

1,200

2,600

100

220

540

1,000

1,700

2,600

1,000

2,300

125

200

490

900

1,400

2,300

900

2,100

150

190

430

830

1,300

2,100

830

1,900

175

170

400

780

1,200

1,900

770

1,700

200

160

380

730

1,100

1,800

720

1,500

Sizing Between First and Second Stage Regulator*

Maximum Propane Capacities listed are based on 2 psig pressure drop at 10 psig setting.

Capacities in 1,000 BTU/hour.

Nominal Pipe Size

Schedule 40

Tubing Size, O.D. Type L

Pipe or

Tubing

Length,

Feet

3/8"

1/2"

5/8"

3/4"

7/8"

1-1/8"

1/2"

3/4"

1"

1-1/4" 1-1/2"

10

39

92

199

329

501

935

275

567

1,071 2,205 3,307

20

26

62

131

216

346

630

189

393

732

1,496 2,299

30

21

50

107

181

277

500

152

315

590

1,212 1,858

40

19

41

90

145

233

427

129

267

504

1,039 1,559

50

18

37

79

131

198

376

114

237

448

91

1,417

60

16

35

72

121

187

340

103

217

409

834

1,275

80

13

29

62

104

155

289

89

185

346

724

1,066

100

11

26

55

90

138

255

78

162

307

630

976

125

10

24

48

81

122

224

69

146

275

567

866

150

9

21

43

72

109

202

63

132

252

511

787

200

8

19

39

66

100

187

54

112

209

439

665

250

8

17

36

60

93

172

48

100

185

390

590

Pipe or

Tubing

Length,

Feet

Nominal Pipe Size

Schedule 40

Tubing Size, O.D. Type L

Sizing Between Second Stage and Appliance Regulator*

Maximum Propane Capacities listed are based on 2 psig pressure drop at 10 psig setting.

Capacities in 1,000 BTU/hour.

C

IRCULATING

A

IR

AND

F

ILTERS

N

EVER

ALLOW

THE

PRODUCTS

OF

COMBUSTION

,

INCLUDING

CARBON

MONOXIDE

,

TO

ENTER

THE

RETURN

DUCT

WORK

OR

CIRCULATION

AIR

SUPPLY

.

WARNING

Duct systems and register sizes must be properly designed for

the CFM and external static pressure rating of the furnace.

Ductwork should be designed in accordance with the recom-

mended methods of “Air Conditioning Contractors of America”

Manual D.

A duct system must be installed in accordance with Standards

of the National Board of Fire Underwriters for the Installation of

Air Conditioning, Warm Air Heating and Ventilating Systems.

Pamphlets No. 90A and 90B.