Warning, Specifications, Unpacking – Harbor Freight Tools 97503 User Manual

Page 9: Initial set up instructions, List of contents, Assembly

Page 9

SKU 97503

For technical questions, please call 1-800-444-3353.

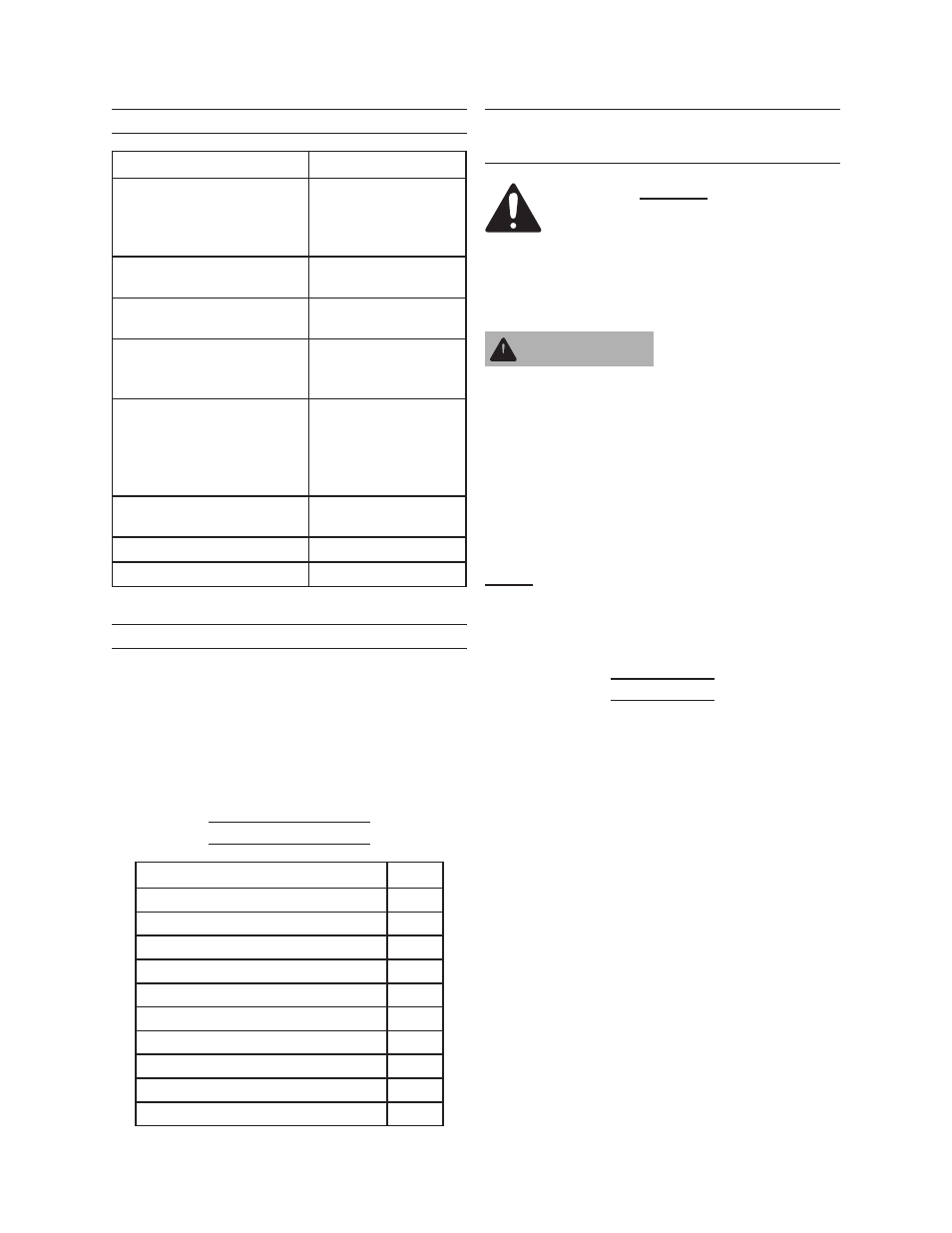

SpecIFIcatIOnS

Welding Current

30 ~ 120 amps

Duty Cycle

20% at 105 amps;

40% at 75 amps;

90% at 50 amps;

100% at 30 amps

Input Power

230 VAC, 21 amps

(Peak) at 60 Hz

Open Circuit Voltage

(max)

36 VDC

Thermal Overload

Protection with Light

Automatic shutdown

and restart after cool

down

Wire Size

0.023 to 0.030 inch

steel and stainless

steel; 0.030 to 0.035

inch flux core and

aluminum

Welding Capacity

22 gauge to 3/16”

Steel

Wire Spool Size

2 lb. Spool

Weight

62.2 lbs.

unpackInG

When unpacking, check to make sure

that the item is intact and undamaged. If

any parts are missing or broken, please

call Harbor Freight Tools at the number

shown on the cover of this manual as soon

as possible.

list of contents

Description

Qty

Dual MIG Welder

1

Wheel

2

Axle

1

0.030” (0.8mm) Welding Tip

1

0.040 (1.0mm) Welding Tip

1

2 Pounds (0.030”) Flux Core Wire

1

Hand Held Shaded Face Shield

1

Brush Hammer

1

Welder Tip Close End Wrench

1

24” Strap For Gas Bottle

2

InItIal Set up

InStructIOnS

read the entIre IMpOrtant

SaFetY InFOrMatIOn section

at the beginning of this manual

including all text under

subheadings therein before set

up or use of this product.

tO preVent

SerIOuS InjurY

FrOM accIDental

OperatIOn:

turn the power Switch of the

tool to its “OFF” position and

unplug the tool from its

electrical outlet before

assembling or making any

adjustments to the tool.

note: For additional information regarding

the parts listed in the following pages,

refer to the Assembly Diagram near

the end of this manual.

assembly

Slide the Axle (29) through the holes

1.

at the rear of the unit.

Secure both Wheels (28) to the Axle

2.

with the Locking Rings (42).

Lift up the Side Panel B (1) to

3.

expose the wire spool and Wire

Feed Mechanism (10). Pull back on

the Feed Tensioner (CC) to free the

Feed Tension Arm (DD) and lift it up.

Remove Wire Feed Wheel Cover

(AA) screws, pull out the cover, and

pull out the Wire Feed Wheel (BB).

See photo page 10.

Note the two parallel grooves (one

4.

is wider) on the circumference of the

Wire Feed Wheel (BB). On the sides

warnInG