Troubleshooting guide – Harbor Freight Tools 90692 User Manual

Page 12

SKU 90692

PAGE 12

occurs, have the problem corrected before further use.

Do not use damaged equipment.

2.

For better and safer performance, always keep the Cutting Tool (31) clean and

sharp.

3.

Daily, with a clean cloth, brush, or vacuum remove all debris fromthe Lathe Dupli-

cator Attachment. Then, use a lightweight machine oil to lubricate all moving

parts.

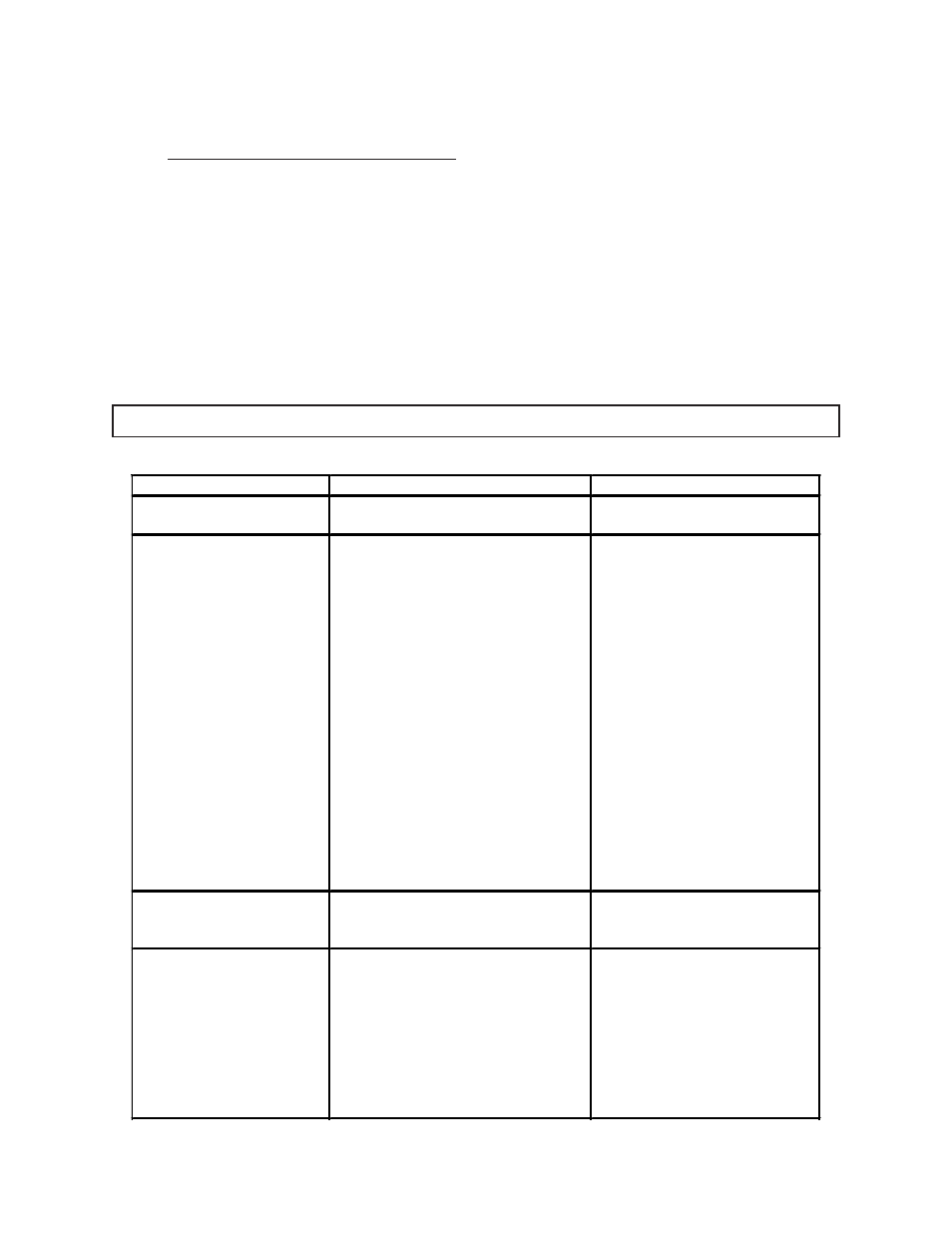

TROUBLESHOOTING GUIDE

Symptom

Possible Cause(s)

Corrective Action

Machine slows down

while operating.

1.

Applying too much

pressure to workpiece.

1. Ease up on pressure.

Tool “chatters” during

turning operation.

1.

Workpiece is too

far out of round.

2.

Workpiece has too

much wobble.

3.

Operator using

improper technique.

4.

Cutting motion is against

the grain of the workpiece.

5. Workpiece is too long and thin,

and is deflected by tool

pressure.

1.

True up the roundness

of the workpiece before

turning operation.

2.

Establish new center

marks on ends to reduce

wobble.

3.

Read instructions, and

take lighter cuts to

minimize chatter.

4.

Use cutting motion that is

with the grain.

5.

Install a steady rest in the

middle, behind the

workpiece.

Workpiece splits or

breaks up during

turning operation.

1.

Workpiece contained defects

before mounting.

1.

Select or assemble a

workpiece that is free

of defects.

Workpiece finish poor.

1.

Prototype or template loose.

2.

Loose tool holder.

3. Pattern follower not

contacting original.

1.

Secure prototype or

template.

2.

Tighten tension of spring.

3. Adjust pattern follower

firmly against original.