Holding the torch – Harbor Freight Tools 55167 User Manual

Page 17

For technical questions, please call 1-800-444-3353;

Troubleshooting section at end of manual.

Page 17

SKU 55167

objects, turn the Power Switch to the ON position.

6.

Orient yourself on the area to be welded, then place the Face Shield over your eyes.

Warning: Never look at the ignited arc without ANSI approved, arc shaded, eye protec-

tion in a full face shield. Permanent eye damage or blindness can occur. Skin burns

can occur. Never breathe arc fumes.

HOLDING THE TORCH

7.

Hold the Torch (1) in one hand and the face shield in the other.

If a hands-free welding shield (not included, see #7, page 6 for

guidelines) is used, then both hands can be used to control the

Torch. The welding wire should be directed straight into the joint.

This gives an angle of 90° (straight up and down) for groove

(end to end) welds, and an angle of 45° for fillet (T-shaped)

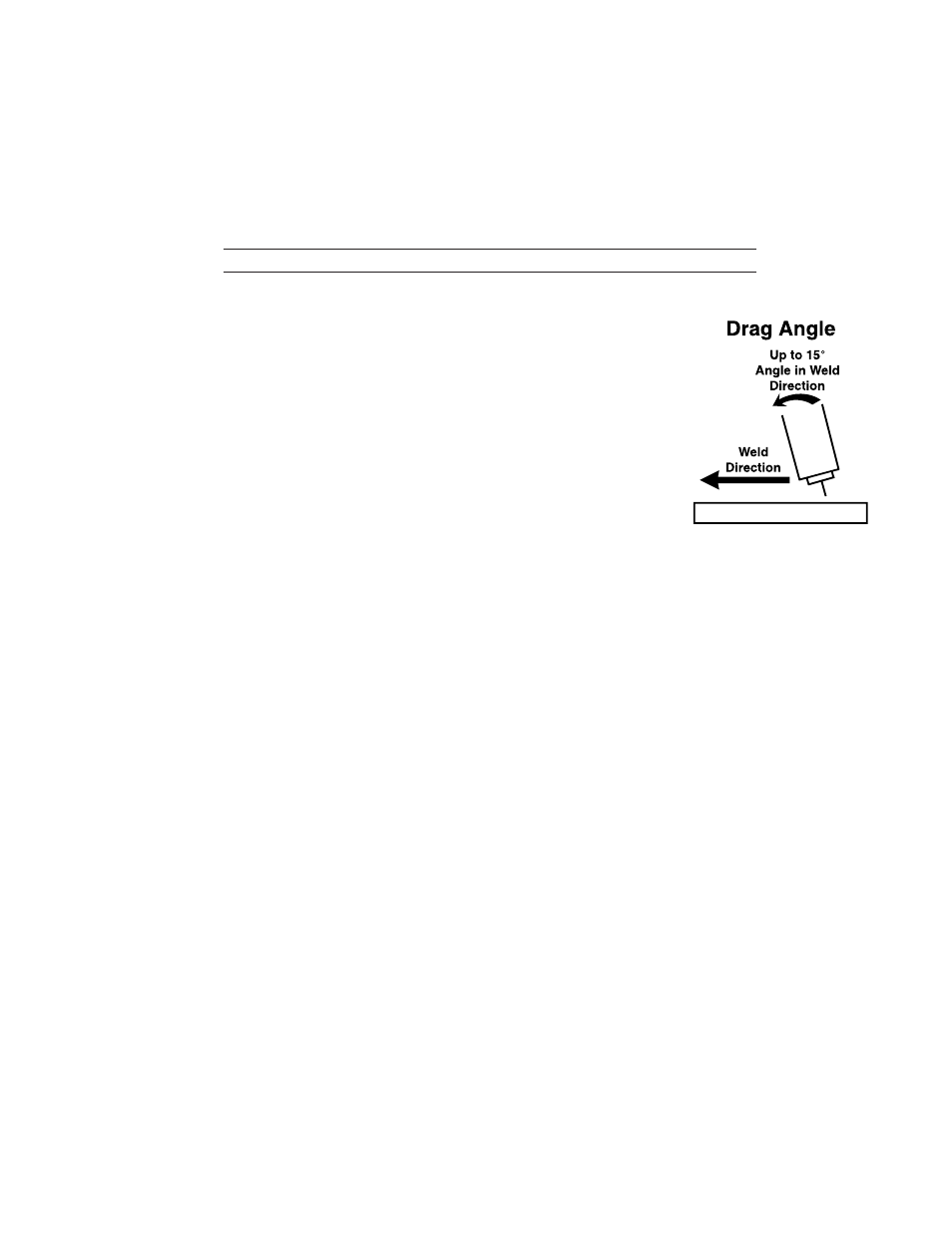

welds. The end of the gun should be tilted so that the wire is

angled anywhere in-between straight on and 15° in the direction

of the weld. The amount of tilt is called the

drag angle - see

illustration, right. The welding wire should extend no more than

1

/

2

” past the tip (this distance is called

stickout).

8.

Set the Wire Feed Control Knob (9) to the recommended start setting as shown in the

chart on the next page. Press (and hold) the Trigger Switch (1c) and stroke the area

to be welded with the electrode wire to ignite the arc.

Never tap the electrode wire into the welding surface to ignite the arc. This will cause

the welding wire to stick to the workpiece.

For a narrow weld, you can usually draw the wire in a steady straight line, this is called

a

stringer bead.

For a wider weld, draw the wire back and forth across the joint in a curve, this is called

a

weave bead.

Note: If too much current is drawn from the Flux Wire Welder, the Thermal Overload protector

will activate, the amber indicator will light, and the Arc Welder will turn off until it cools down.

If this happens, turn the Power Switch to the OFF position and wait about 3 ~ 5 minutes.

9.

After a few seconds, stop, switch off the welder, and check the progress. Compare

your weld’s appearance with the diagrams and descriptions in the

Weld Diagnosis

section starting on page 19. After making any necessary adjustments, continue the

weld

while carefully following the Duty CyCle guidelines as explained on page

15.