Preventive maintenance – Heatcraft Refrigeration Products II User Manual

Page 31

31

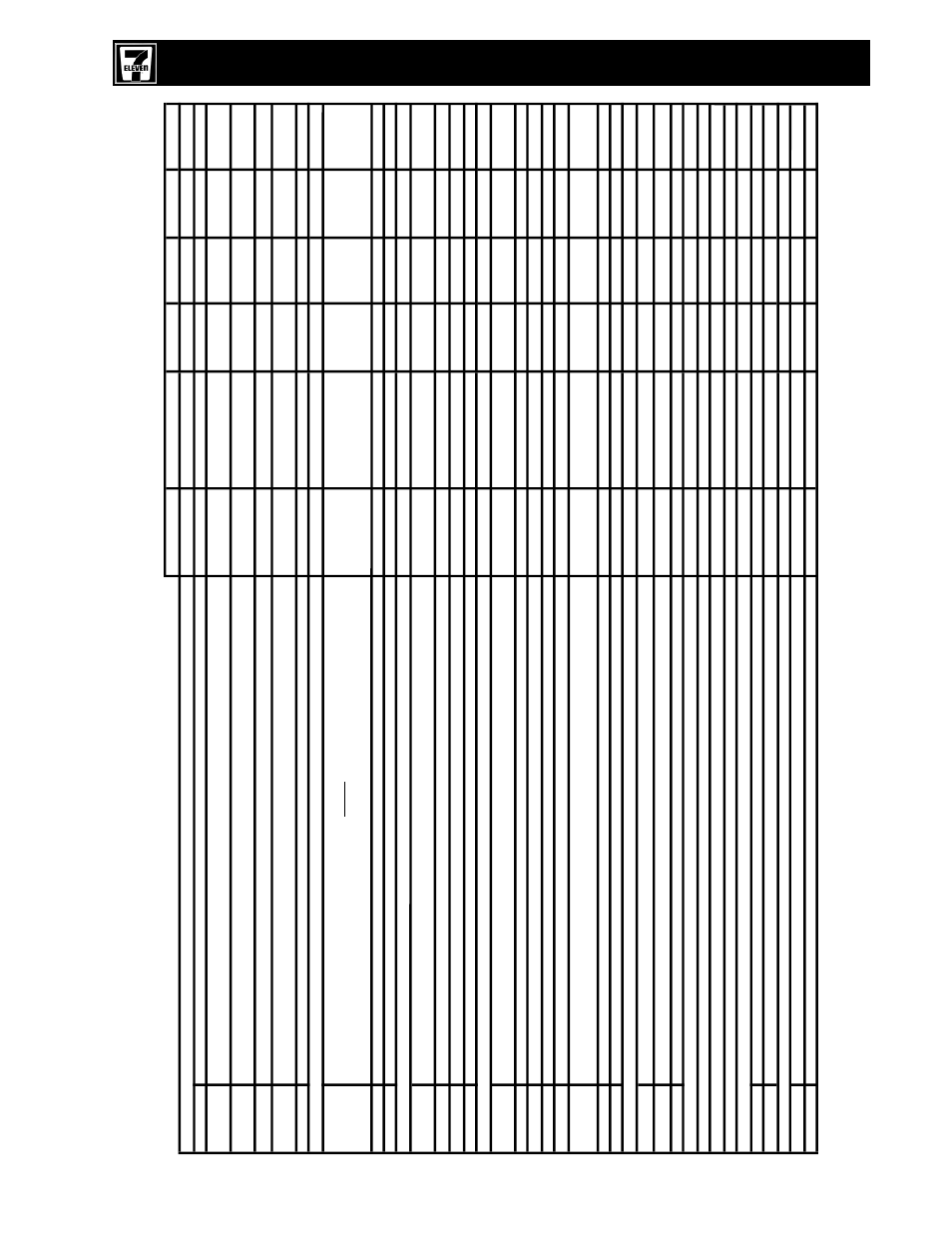

Preventive Maintenance

UNIT COOLERS

QUARTERLY

SEMI-ANNUALLY

DATE

DATE

DATE

DATE

Visually inspect unit

✔✔

1

Look for signs of corrosion on fins, cabinet, copper tubing and solder joints

✔✔

2

Look for excessive or unusual vibration for fan blades or sheet metal panels when in operation.

Identify fan cell(s) causing vibration and check motor and blade carefully.

✔✔

3

Look for oil stains on headers, return bends, and coil fins. Check any suspect areas with an

electronic leak detector.

✔✔

4

Check drain pan to insure that drain is clear of debris, obstructions or ice build-up and is free

draining

✔✔

5

Insure that there is sufficient clearance free of obstructions around unit coolers to allow proper

airflow through coils

✔✔

6

Verify Box setpoint temperature is being met

✔✔

Clean Evaporator coil and blades

✔

1

Periodic cleaning can be accomplished by using a brush, pressurized water or a commercially

available Evaporator Coil Cleaner or mild detergent.

Never

use an acid based cleaner. Always

follow label directions for appropriate use. Be sure the product you use is approved for use in food

service applications.

✔

2

Flush and rinse coil until no residue remains.

✔

3

Pay close attention to drain pan, drain line and trap.

Check the operation of all fans and ensure airflow is unobstructed

✔

1

Check that each fan rotates freely and quietly. Replace any fan motor that does not rotate

smoothly or makes an unusual noise.

✔

2

Check all fan set screws and tighten if needed.

✔

3

Check all fan blades for signs of stress or wear. Replace any blades that are worn, cracked or bent.

✔

4

Verify that all fan motors are securely fastened.

✔

Inspect electrical wiring and components

✔

1

Visually inspect all wiring for wear, kinks, bare areas and discoloration. Replace any wiring found to

be damaged

✔

2

Verify that all electrical and ground connections are secure, tighten if necessary.

✔

3

Check operation/calibration of all fan cycle and defrost controls when used.

✔

4

Look for abnormal accumulation of ice patterns and adjust defrost cycles accordingly

✔

5

Compare actual defrost heater amp draw against unit data plate. (freezer only)

✔

6

Visually inspect heaters to ensure even surface contact with the coil. If heaters have creeped

decrease defrost termination temperature and be sure you have even coil frost patterns. (freezer

only)

✔

7

Check low voltage wiring at Beacon board for broken wires

✔

8

Check voltage at Beacon board. Should be between 18 to 30 Volts

✔

Check Beacon sensors

✔

1

Press MONITOR button to display sensor reading for Box Temp., Suction Temp. and Defrost Temp.

✔

2

Use an accurate Thermometer to measure temperatures at the same locations as the sensors.

✔

3

LED readings should match measured values, within 3 °F at same locations as sensors.

✔

Check Beacon Pressure Transducer

✔

1

Press MONITOR button to display Suction Pressure reading at the Evaporator

✔

2

Use an accurate Gauge Set to measure Evaporator Pressure.

✔

3

Measured suction pressure should match LED displayed value within 2 Psig.

✔

k Drain Line Heater

✔

1

Check heater amps

✔

2

Check that heater is wrapped around entire length of drain line inside the walk-in freezer

✔

Refrigeration Cycle

✔

1

Check unit cooler superheat and compare reading for your specific application

✔

2

Visually inspect coil for even refrigerant distribution

✔