Harbor Freight Tools CENTRAL MACHINERY 95668 User Manual

Page 23

SKU 95668

For technical questions, please call 1-800-444-3353

PAGE 23

2.

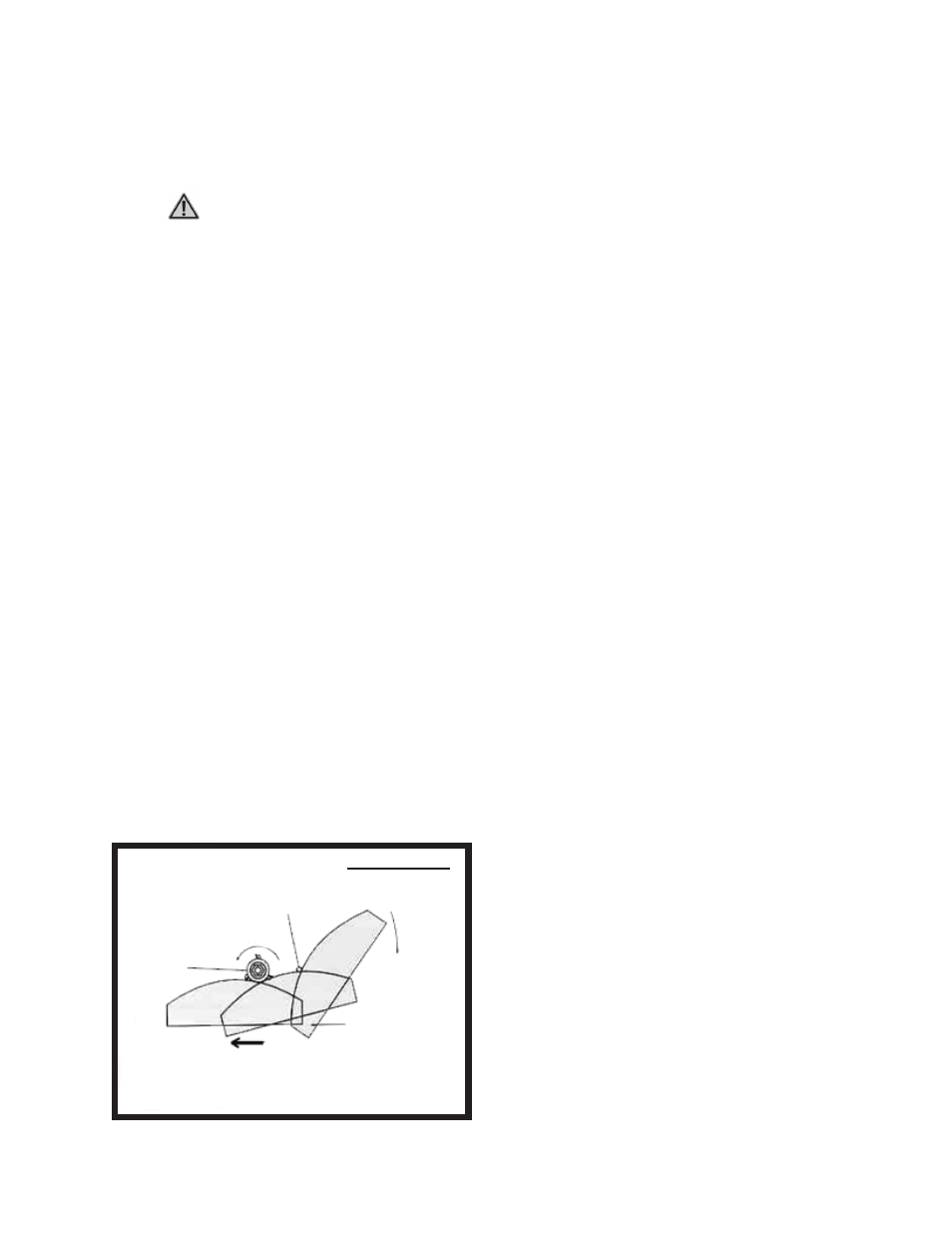

To reduce this tendency, use a Taper Pin (56). The Taper Pin allows you to

anchor and slowly pivot the workpiece into the Cutter as the cut is started. Thus,

shaping freehand is more stable and safer.

(See Figures HH).

WARNINg! ALWAYS use an auxiliary jig (not included) and extreme care

when shaping with the Fences (60) removed. Freehand shaping often requires

you to remove the Fences, resulting in reduced protection from the Cutter.

3.

To set up the Wood Shaper for freehand shaping, remove the Fences (60) from

the machine.

4.

Insert the Taper Pin (56) in the best suited hole on the Work Table (52) so you

can feed the workpiece into and against the rotation of the Cutter.

(See Figures HH).

5.

Install the Cutter so it will cut in the correct direction. Then, adjust the Spindle

(105) height.

6.

Install the Ring Guard (85). DO NOT use the Wood Shaper without the Ring

Guard installed.

7.

Use a supplemental hold-down jig (not included), or you can use rubberized-

handle push blocks (not included) to support or guide the workpiece and protect

your hands.

8.

Place the workpiece against the Taper Pin (56).

(See Figures HH).

9.

Slowly pivot and feed the workpiece into the Cutter. Avoid starting the cut on the

corner of the workpiece as kickback could occur. Once the cut is started, the

workpiece should be pulled away from the Taper Pin (56).

(See Figures HH).

TAPER PIN

(56)

SWINg

FEED

WORKPIEcE

ROTATION

RUB cOLLAR

(98, 99, 100)

FIgURE HH