Operation instructions – Harbor Freight Tools 95801 User Manual

Page 8

Page 8

SKU 95801

For technical questions, please call 1-800-444-3353.

(1A). Slide one Retainer Ring (8A) around the Needles (5A) and fasten it at the

front end of the Barrel Assembly (1A). See

Figures 4 & 4A

2.

Figure 5

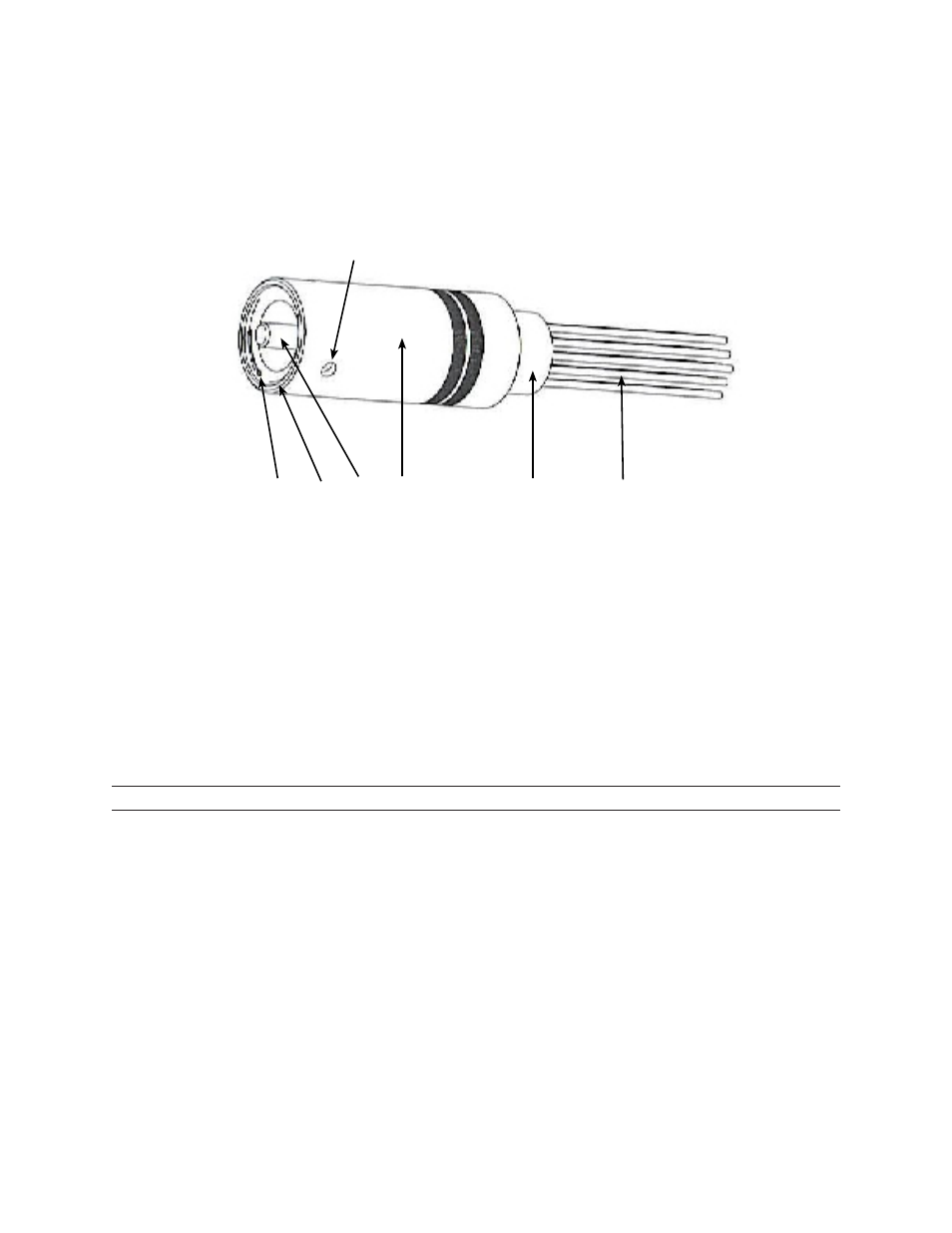

8A 7A 6A 1A 2A 5A

Hole for Set Screw

Holding the Barrel Assembly (1A) in one hand with the Needles (5A) pointing down-

ward, insert the Needle Driver (6A), the Screw Cap (7A) and the last Retainer Ring

(8A). See

Figures 4 & 5

3.

The Screw Cap (7A) has a Set Screw that holds it in place. Be very careful NOT

to tighten the Set Screw too tightly, snug is good. Otherwise you may damage the

plastic threads inside the Screw Cap (7A) causing it to bind or strip some threads.

4.

Insert the Barrel Assembly (1A) into the end of the Air Hammer Housing (1) and

thread the two parts together. As before do not over tighten, snug is good.

5.

The Air Hammer is now ready to be used as a Scaler.

OPERATION INSTRUCTIONS

1.

With the proper tool attached to the Air Hammer, attach your air supply to the Air

Inlet (7) at the base on the Housing (1). Turn on the air supply. Carefully place the

tool against the surface of the project you are working with. Make sure the project

is in a vise or attached to something that holds it securely so it cannot be moved

out of position.

2.

Set the Air Regulator (11) located at the base of the Housing (1).

Air pressure

should not exceed 90 PSI. Test the action of the Air Hammer and adjust the

Air Regulator (11) as necessary.

3.

Use a light touch on the Trigger (8). Never force the Air Hammer against the surface

you are working with. Easy, light pressure works best.

WARNING: If the Air Hammer is being used as a Scaler, use a ANSI-approved full

face shield and not just safety goggles to protect against Needles that may snap

off and could possibly cause personal injury.