Refrigeration oils, Polyol ester lubricants, Mineral oil – Heatcraft Refrigeration Products H-IM-FL1A User Manual

Page 6

6

Mineral Oils

The BR and Scroll compressors use Sontex 200, a “white oil”.

This oil is not suitable for low temperature applications nor is

it available through the normal refrigeration wholesalers. For

field “top-off” the use of 3GS or equivalent, or Zerol 200TD

is permissible, as long as at least 50% of the total oil charge

remains Sontex 200.

Suniso 3GS, Texaco WF32 and Calumet R015 (yellow oils) are

available through normal refrigeration wholesalers. These oils

are compatible if mixed and can be used on both high and low

temperature systems.

Polyol Ester Lubricants

The Mobil EAL ARCTIC 22 CC is the preferred Polyol ester due to

unique additives included in this lubricant. ICI Emkarate RL 32S is

an acceptable Polyol ester lubricant approved for use when Mobil

is not available. These POEʼs

must be used if HFC refrigerants are

used in the system. They are also acceptable for use with any

of the traditional refrigerants or interim blends and are

compatible with mineral oils. They can therefore be mixed

with mineral oils when used in systems with CFC or HCFC

refrigerants. These lubricants are compatible with one another

and can be mixed.

Alkyl Benzenes

Zerol 200TD is an alkyl benzene (AB) lubricant. Copeland

recommends this lubricant for use as a mixture with mineral oil

(MO) when using the interim blends such as R-401A, R-401B

and R-402A (MP39, MP66 and HP80). A minimum of 50% AB is

required in these mixtures to assure proper oil return.

Shell MS 2212 is a 70/30 mixture of AB/MO. If this lubricant is

used in a retrofit situation virtually all of the existing MO must be

drained prior to refilling with the MS 2212 to assure a minimum

50% AB content.

Table 3. Refrigeration Oils

Refrigeration Oils*

With the changes that have taken place in our industry due to

the CFC issue, we have reevaluated our lubricants to ensure

compatibility with the new HFC refrigerants and HCFC interim

blends offered by several chemical producers. As a secondary

criteria, it is also desirable that any new lubricant be compatible

with the traditional refrigerants such as CFC-12, HCFC-22 or

R502. This “backward compatibility” has been achieved with the

introduction of the Polyol ester lubricants.

Table 3 below summarizes which oils/lubricants are approved

for use in Copeland compressors:

Polyol Ester Lubricants

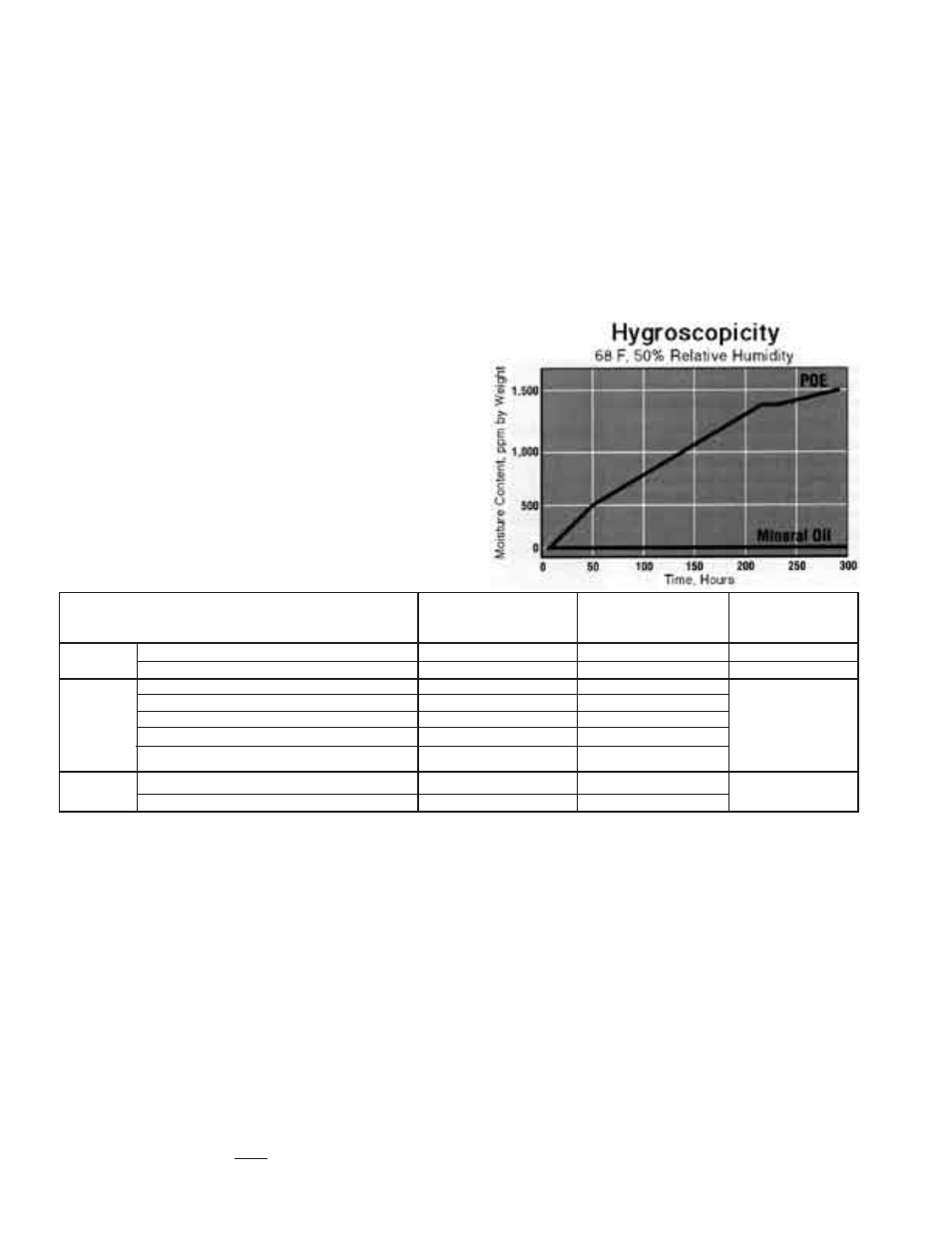

Hygroscopicity

Ester lubricants (POE) have the characteristic of quickly

absorbing moisture from the ambient surroundings. This is

shown graphically in Figure 3 where it can be seen that such

lubricants absorb moisture faster and in greater quantity than

conventional mineral oils. Since moisture levels greater than

100 ppm will results in system corrosion and ultimate failure, it

is imperative that compressors, components, containers and the

entire system be kept sealed as much as possible. Lubricants

will be packaged in specially designed, sealed containers.

After opening, all the lubricant in a container should be used at

once since it will readily absorb moisture if left exposed to the

ambient. Any unused lubricant should be properly disposed of.

Similarly, work on systems and compressors must be carried

out with the open time as short as possible. Leaving the system

or compressor open during breaks or overnight MUST BE

AVOIDED!

Color

As received, the POE lubricant will be clear or straw colored.

After use, it may acquire a darker color. This does not indicate

a problem as the darker color merely reflects the activity of the

lubricantʼ s protective additive.

Oil Level

During Copelandʼ s testing of Polyol ester oil, it was found that

this lubricant exhibits a greater tendency to introduce oil into the

cylinder during flooded start conditions. If allowed to continue,

this condition will cause mechanical failure of the compressor.

A crankcase heater is required with condensing units and it

must be turned on several hours before start-up.

Oil level must not exceed 1/4 sight glass.

Mineral Oil

Figure 3.

Interims

HFCʼs

Traditional Refrigerants R401A, R401B, R402A

HFC-134a,

Refrigeration Oils

HCFC-22

(MP-39, MP-66, HP-80)

R404A, R507

POEʼs

Mobil EAL ARCTIC 22 CC

A

A

P

ICI (Virginia KMP) EMKARATE RL 32CF

A

A

P

Suniso 3GS

P

PM

Mineral

Texaco WF32

P

PM

NOT

Oils

Calumet RO15 (Witco)

P

PM

ACCEPTABLE

Sontex 200-LT (White Oil)

(BR & Scroll Only)

Witco LP-200

P

A/B

Zerol 200TD

AM

PM

NOT

Soltex Type AB-200

PM

ACCEPTABLE

P = Preferred Lubricant Choice A = Acceptable Alternative M = Mixture of Mineral Oil and Alkyl Benzene (AB) with minimum 50% AB.

* (Reprinted with permission from Copeland)