Notice, Air supply maintenance, Storage – Harbor Freight Tools CENTRAL PNEUMATIC 92841 User Manual

Page 16: Troubleshooting - spray pattern diagnosis

NOTICE

Clean the Spray Gun IMMEDIATELY after use.

Delayed or inadequate cleaning will permanently clog the Spray Gun.

Page 16

For technical questions, please call 1-800-444-3353.

Item 92841

SAFETY

Op

ERA

TION

M

AINTENANCE

SETU

p

Air Supply Maintenance

Every day, perform maintenance on the air supply according

to the component manufacturers’ instructions.

Storage

Store in a dry, secure area out of reach of children.

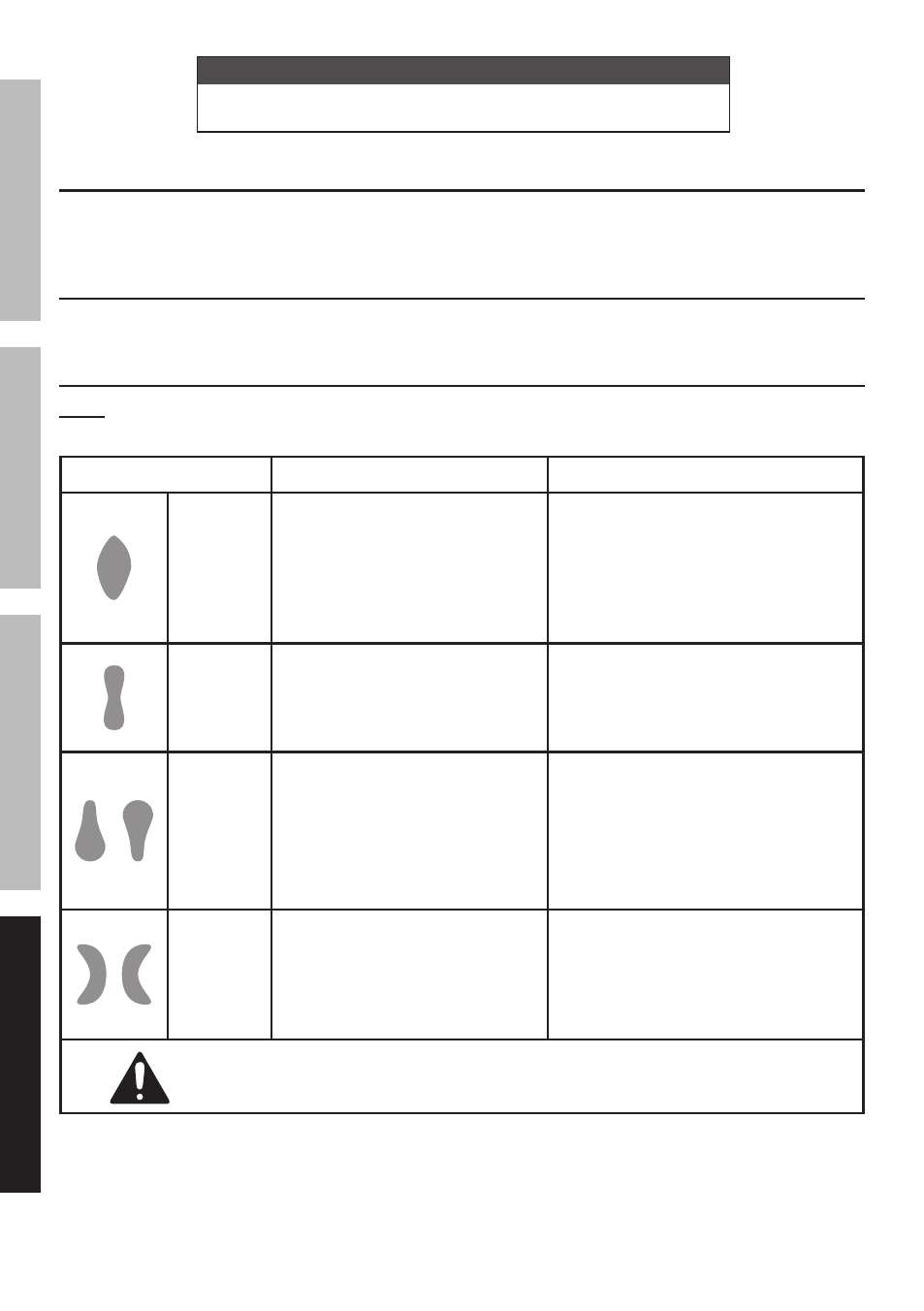

Troubleshooting - Spray pattern Diagnosis

Note: The drawings on the left below resemble symptoms of spray pattern problems.

Refer to the accompanying possible causes and likely solutions to the right.

problem

possible Causes

Likely Solutions

Heavy

center

pattern

1. Pattern Adjustment

Knob partially closed.

2. The paint is too thick.

3. The air pressure is too low.

1. Open Pattern Adjustment

Knob more.

2. Thin paint according to the

manufacturer’s instructions.

3. Increase air pressure within

the Operating Air Pressure.

Light

center

pattern

1. High air pressure.

2. Fluid Knob not open enough.

3. Pattern Adjustment

Knob open too far.

1. Reduce air pressure.

2. Open Fluid Knob.

3. Partially close Pattern

Adjustment Knob.

Heavy top/

bottom

pattern

1. Nozzle plugged.

2. Nozzle loose or dirty seal.

3. Dried paint on fluid tip.

4. Damaged Needle.

1. Clean Nozzle.

2. Clean and tighten Nozzle and seal.

3. Use a nonmetallic point

to clean Nozzle.

4. Have qualified technician

replace Needle.

Pattern

on right or

left only

1. Dirt on one side of fluid tip.

2. Holes on one side of

Nozzle are plugged.

3. Damaged Needle.

1. Clean fluid tip.

2. Clean Nozzle with nonmetallic point.

3. Have qualified technician

replace Needle.

Follow all safety precautions whenever diagnosing or servicing the tool.

Disconnect air supply before service.