Sequence of cutting operation, 5. sequence of cutting operation – Hobart Welding Products 625 User Manual

Page 23

.

A complete Parts List is available at www.HobartWelders.com

OM-926 Page 19

out bottom of cut.

801 400-B

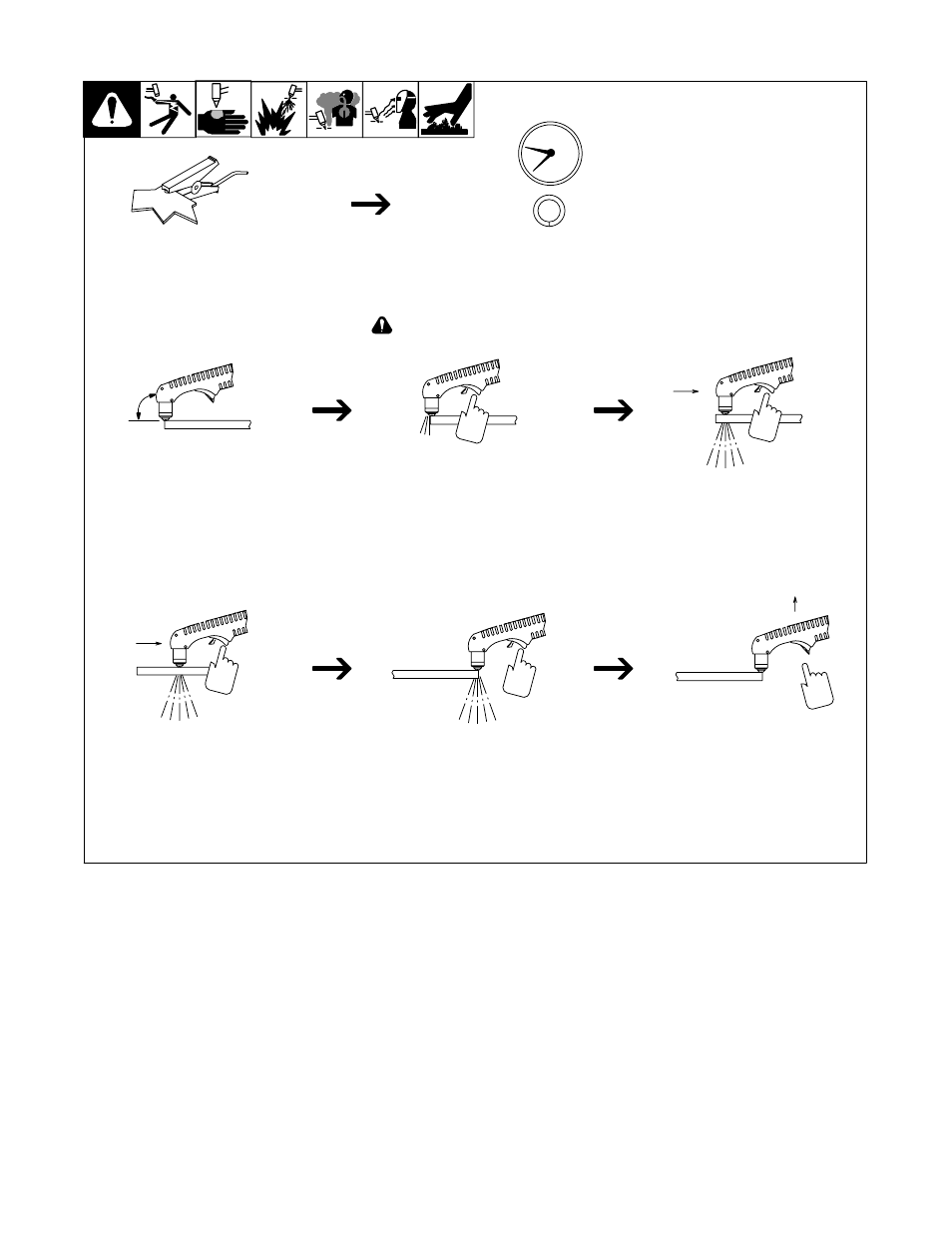

5-5. Sequence Of Cutting Operation

After cutting arc starts, slowly

start moving torch across metal.

Adjust torch speed so

sparks go thru metal and

Pause briefly at end of

cut before releasing trigger.

Raise trigger lock and press

trigger. Pilot arc starts.

Postflow continues for approx. 20 seconds

after releasing trigger; cutting arc can be

instantly restarted during postflow by raising

trigger lock and pressing trigger.

The pilot arc starts immediately

when trigger is pressed.

For standard (shielded) cutting, place drag

shield on edge of metal. For extended

(non-shielded) cutting, use 1/8 in (3.2 mm)

standoff distance (dragging tip will reduce tip

life).

Connect work clamp to a clean, paint-free

location on workpiece, as close to cutting

area as possible.

.

Set air pressure to 75 PSI (517 kPa) for cutting.

90

°

- XTP (16 pages)

- IRONMAN M-10 (56 pages)

- HANDLER 140 217 694E (48 pages)

- OM-1594 (68 pages)

- DP-3035 (28 pages)

- 250A (32 pages)

- 175 (52 pages)

- OM-947 (48 pages)

- CHAMP 2060 (60 pages)

- 120 (48 pages)

- OM-494 (76 pages)

- 302 (40 pages)

- DP 3035-10 (32 pages)

- CHAMPION 4500 210 597J (52 pages)

- OLYMPIC R-115 (36 pages)

- HOOD XVX (20 pages)

- HANDLER 180 (52 pages)

- STICKMATE OM-950 (40 pages)

- 3035-20 (32 pages)

- H-9A Gun (24 pages)

- HANDLER 210 (52 pages)

- OM-948 (24 pages)

- 187 (52 pages)

- AIRFORCE 375 OM-2210 (32 pages)

- ARCSTAR OM-487 (60 pages)

- 300 AC (32 pages)

- Stickmate 205 AC (2 pages)

- AIRFORCE HP-25 TORCH (36 pages)

- 1435 (60 pages)

- AIRFORCE 250A (32 pages)

- 000 OM-945 194 047U (64 pages)

- 000 OM-945 (68 pages)

- CHAMPION OM-493 (56 pages)

- CHAMPION ELITE OM-240 438E (64 pages)

- AIRFORCE OM-230 455D (36 pages)

- SPOOL GUN DP 3035-20 (32 pages)

- OLYMPIC S-62 (36 pages)

- SPOOL GUN 3035-20 (2 pages)

- STICKMATE OM-949 (36 pages)

- HANDLER 210 OM-227 978B (52 pages)

- AIRFORCE OM-928 (32 pages)

- AIRFORCE 700I (40 pages)

- IRONMAN 230 (56 pages)

- HANDLER 210 MVP (56 pages)

- ARCSTAR 280 NT (52 pages)