11. installing alternative plug, 12. setting gas/air pressure – Hobart Welding Products 625 User Manual

Page 20

.

A complete Parts List is available at www.HobartWelders.com

OM-926 Page 16

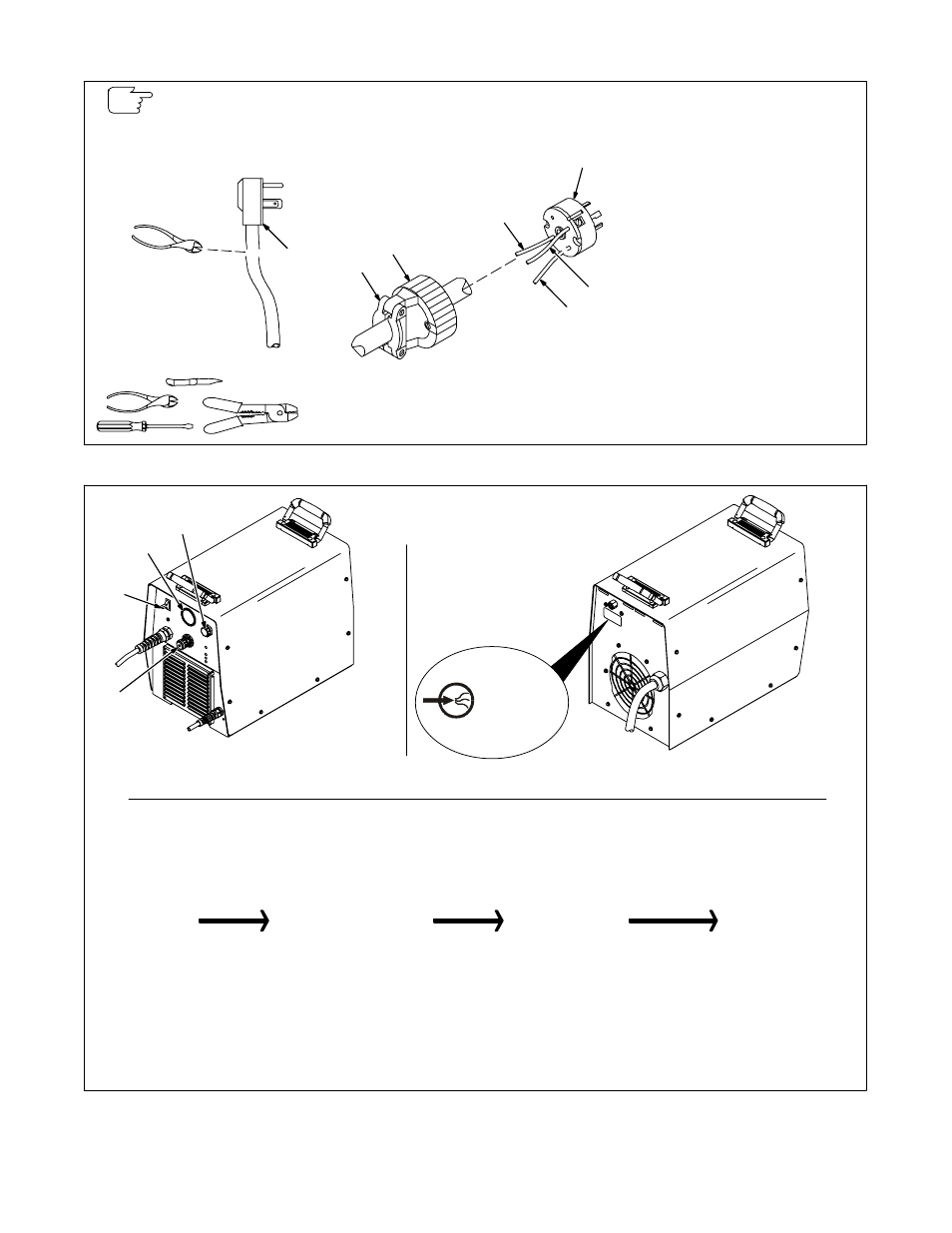

4-11. Installing Alternative Plug

1

Supplied 230 VAC Plug

Cut cord close to plug.

2

Alternative Plug (230 VAC

Plug Shown)

3

Input (Black Lead)

(Brass) Terminal

4

Neutral (White Lead)

(Brass) Terminal

5

Ground (Green) Terminal

6

Outer Shell

7

Cord Grip

Strip cord jacket back enough to

separate conductors.

Strip conductors enough to make

good contact with plug terminals.

Make plug connections and reinstall

outer shell and cord grip. Tighten

assembly screws onto shell. Do not

overtighten.

Ref. 801 305-A / 801 611

This procedure is necessary if the unit is to be connected to a 208/230 VAC

receptacle that requires a plug that is different from the supplied plug.

Tools Needed:

1

6

7

2

3

4

5

1

Power Switch

Place power switch in On position

2

Output Control

Place output control in Gas/Air position.

3

Pressure Gauge

4

Gas/Air Pressure Adjustment Knob

Adjust pressure to 75 psi (517 kPa) on

pressure gauge by pulling and turning knob.

Push knob in to lock setting.

Select desired cutting output with Output

Control.

4-12. Setting Gas/Air Pressure

Ref. 803 219 / Ref. 803 221

2

Set Controls

Turn On Gas/Air Supply

Adjust Pressure

On Unit

Select Desired

Amperage To

Begin Cutting

Set To 75 PSI (517 kPa) For Cutting

Or 55 PSI (379 kPa) For Gouging

Requires

90−120 PSI Supply

(621−827 kPa)

Setting Gas/Air Pressure

Place Output Control in

Gas/Air Set Position

Power Switch On

Rear of Unit

1

4

3

AIR/N

2

90-120 psi