Assembly step – Horizon Fitness ASCENT TRAINER AT1501 User Manual

Page 8

BEFORE

YOU BEGIN

1

INTRODUCTION

IMPORT

ANT

PRECAUTIONS

ASSEMBL

Y

BEFORE

YOU

BEGIN

ASCENT

TRAINER

OPERA

TION

LIMITED

W

ARRANTY

TROUBLESHOOTING

&

MAINTENANCE

CONDITIONING

GUIDELINES

BEFORE YOU

BEGIN

ASSEMBL

Y

15

INTRODUCTION

IMPORT

ANT

PRECAUTIONS

ASCENT

TRAINER

OPERA

TION

CONDITIONING GUIDELINES

TROUBLESHOOTING &

MAINTENANCE

LIMITED WARRANTY

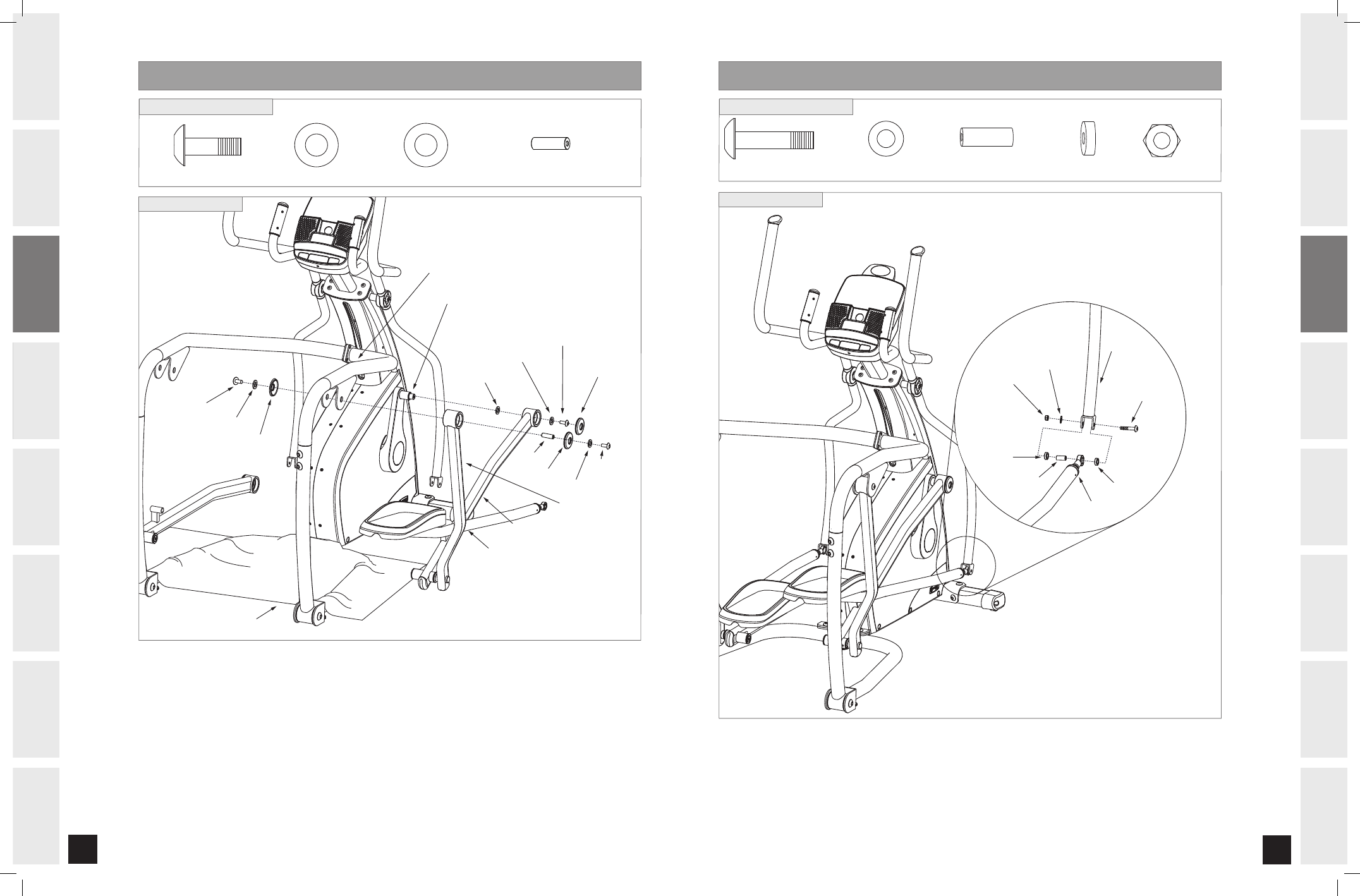

NUT (G)

WASHER (L)

BOLT (N)

SPACER

SPACER

ROD BEARING

SHAFT

LINK ARM

LOWER

HANDLEBAR

WASHER (L)

18 mm

Qty: 2

BOLT (N)

45 mm

Qty: 2

ROD BEARING

SHAFT

Qty: 2

SPACER

Qty: 4

NUT (G)

8 mm

Qty: 2

HARDWARE BAG CONTENTS:

ASSEMBLY STEP :

Open

HARDWARE BAG 9.

Slide 1

ROD BEARING SHAFT into the joint end of right LINK ARM.

Fit 1

SPACER on each side of each ROD BEARING SHAFT after the ROD BEARING SHAFTS are in LINK ARM.

Attach right

LINK ARM to the right LOWER HANDLEBAR using 1 BOLT (N), 1 WASHER (L) and 1 NUT (G).

Repeat on opposite side.

A

B

C

D

E

ASSEMBLY STEP

CRANK

PACKAGING PLASTIC

WASHER (D)

WAVY WASHER (J)

RIGHT SWING ARM

BOLT (C)

CRANK CAP

SWING CAP

TOP HANDRAIL

WASHER (D)

AXLE

BOLT (C)

WASHER (D)

SWING CAP

BOLT (C)

PEDAL ARM

LINK ARM

BOLT (C)

16 mm

Qty: 6

WASHER (D)

25 mm

Qty: 6

WAVY WASHER (J)

29 mm

Qty: 2

AXLE

Qty: 2

HARDWARE BAG CONTENTS:

ASSEMBLY STEP :

Lay waste packaging plastic over the

BASE RAIL. This will prevent the PEDAL ARM assembly from scratching

the ascent trainer’s paint.

Open

HARDWARE BAG 8.

Place 1

WAVY WASHER (J) onto CRANK.

Attach the right

PEDAL ARM of the assembly to the right CRANK using 1 WASHER (D) and 1 BOLT (C).

Attach right

SWING ARM to TOP HANDRAIL using 2 SWING CAPS, 2 BOLTS (C), 1 SHAFT and 2 WASHERS (D).

Attach the

CRANK CAP to the CRANK

Repeat on opposite side.

A

B

C

D

E

F

G

ASSEMBLY STEP

AT1501_Rev.2.6.indd 14-15

7/31/08 12:43:49 PM