Throttling range xpc / xph (p.10 / p11) – Honeywell MICRONIK 200 R7426A User Manual

Page 9

R7426A,B,C TEMPERATURE CONTROLLER WITH AND WITHOUT REAL TIME CLOCK

9

EN1B-0203GE51

R0507C

limit or cascade sensor (T2) to operate the output device from

full open (100%) to full closed (0%) or vice versa.

Xp1 is the throttling range for the main control loop, Xp2 is

used if limitation or cascade control (submaster control loop)

is active (see Table 11).

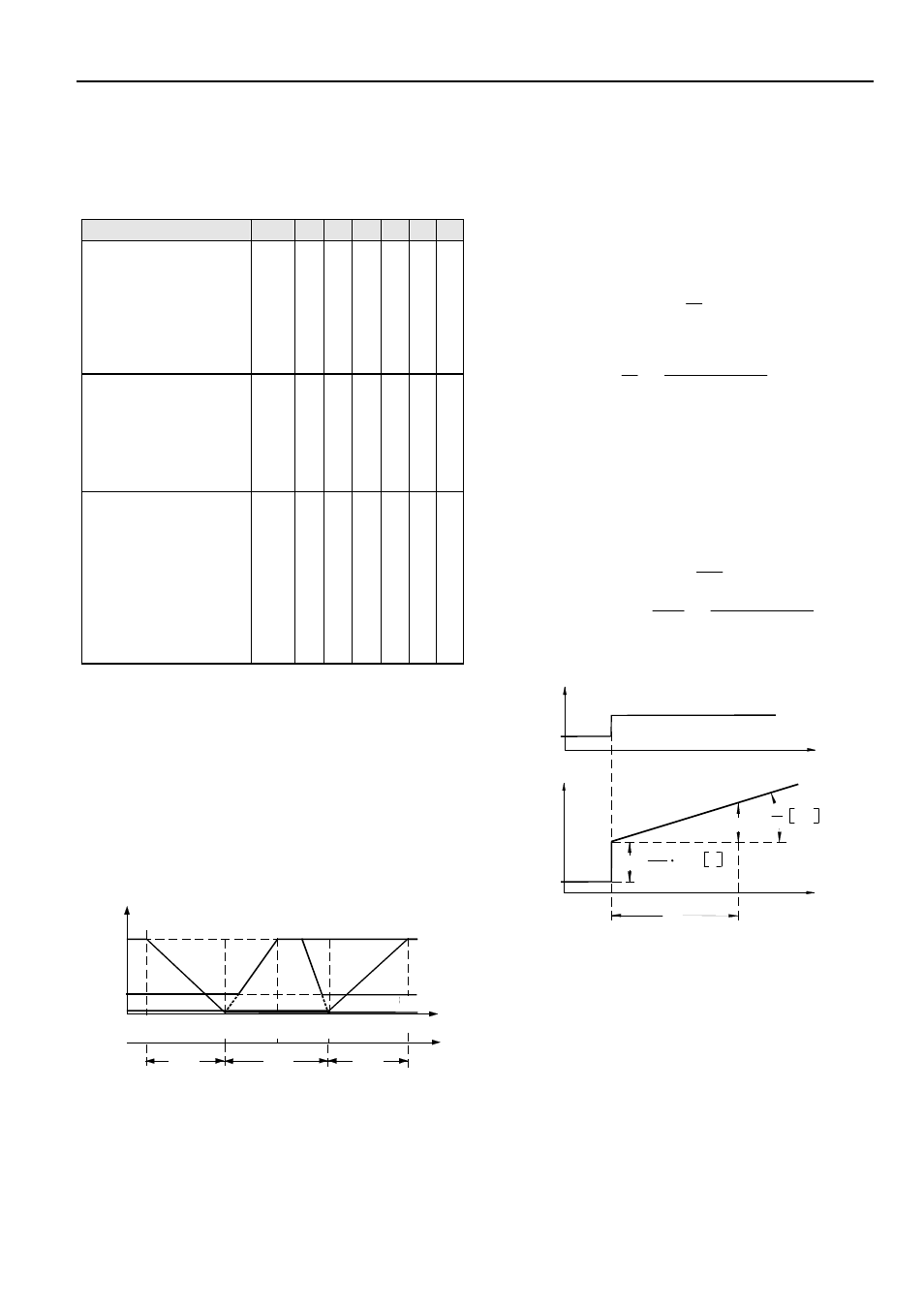

Table 11. Throttling range and reset time reference

application

sens.

Xp1 Xp2 Xpc Xph

tr1 tr2

R7426A

Controller

Main Temp.Control

T1

x

x

High or Low Limit

Temperature Control

T2 x x

Cascade

Control

Master T1

x

x

Submaster T2

x

x

R7426B,C

Controller

Main Temp. Seq. Control

Mixed Air Damper

T1

x

x

Energy Recovery

T1

x

x

Heating T1

x

x

Cooling T1

x

x

R7426B,C

Controller

Temperature Cascade

Sequence Control

Master T1

x

x

Submaster

- Mixed Air Dampers

T2

x

x

- Energy Recovery

T2

x

x

- Heating

T2

x

x

- Cooling

T2

x

x

Throttling Range Xpc / Xph (P.10 / P11)

The control parameters Xpc and Xph are only available on

R7426B,C controllers and are used to set the cooling and

heating throttling ranges for the following applications

• Temperature sequence control with heating, mixed air

dampers, and cooling (see Fig. 3 and Table 11)

• Temperature cascade control with heating, mixed air

dampers, and cooling (see Table 11)

In applications without cooling, the throttling range Xpc must

be set to OFF 100% fresh air supply at actual temperature

above the control point is required (outdoor and return air

dampers fully open).

T2

100

0

Xpc

Cooling

Heating

CTRP1

Xwh / Xwc

Xph

CTRPC

CTRPH

Xp1

Damper

Y[%]

MINPOS

Xwd

/

1/4 Xp1

if Xpc = Off

if Xpc = Off

Y1

Y3

Y2

Fig. 3. Temperature sequence control with heating, mixed

air dampers, and cooling valve

Setting Guidelines for Proportional Band of P and

P+I Control

To estimate the proportional band (throttling range X

p

) for

stable control under all different load conditions, the control or

correcting range X

h

of the heating or cooling coil must be

known. This is the maximum air temperature increase pro-

duced by the heating coil or decrease of a cooling coil if the

control valve is fully open.

The proportional band X

p

for discharge air control can be

calculated by using the following rule-of thumb formula:

X

p

=

X

h

5

For room temperature control, the following rule-of-thumb

formula can be used:

X

p

=

X

h

10

or

∆t

discharge air

max

10

The

∆t

max

(X

h

) of the discharge air for mixed air damper con-

trol is the maximum difference between outdoor air (OA)

temperature and return air (RA) temperature.

X

h

=

ϑ

RA

-

ϑ

OAmin

The often-specified accuracy for room control of

±1 (X

p

= 2K)

allows a discharge air alteration of 20

°C.

In P+I control the same proportional band can be used as for

P control. The following rule-of-thumb formulae are used for

P+I control:

• Discharge air control

X

p

=

X

h

4 5

...

• Room

control

X

p

=

X

h

8 10

...

or

∆t

discharge air

8 ... 10

max

Reset Time tr1 / tr2 (P.12 / P13)

P

P

tr

%/s

t

t

Y

X

w

tr

0

P =

100

X

p

X

w %

Fig. 4. Step change response of P+I control

In the case of combined action including proportional and

integral components (P+I control), the reset time (tr) is

defined as the required time after which the integral part is

equal to the change due to the proportional action for a

predetermined step change in the input variable. See Fig. 4.

The control parameter tr1 sets the reset time of the P+I main

temperature control loop. For limit or submaster cascade

control the control parameter tr2 sets the reset time of these

control loops, e.g. discharge temperature T2 (see Table 11).

If only proportional control is required, parameter tr must be

set to OFF.