Maintenance and inspection – Hitachi DH 24DV User Manual

Page 23

English

23

MAINTENANCE AND INSPECTION

CAUTION: Pull out battery before doing any inspection or maintenance.

1. Inspecting the drill bits

Since use of a dull tool will cause motor malfunctioning and degraded efficiency, replace

the drill bit with a new one or resharpening without delay when abrasion is noted.

2. Check the Mounting Screws

Loose mounting screws are dangerous. Regularly inspect them and make sure they

are tight.

CAUTION: Using this power tool with loosen screws is extremely dangerous.

3. Maintenance of the motor

The motor unit winding is the very “heart” of the power tool.

Exercise due care to ensure the winding does not become damaged and/or wet with oil

or water.

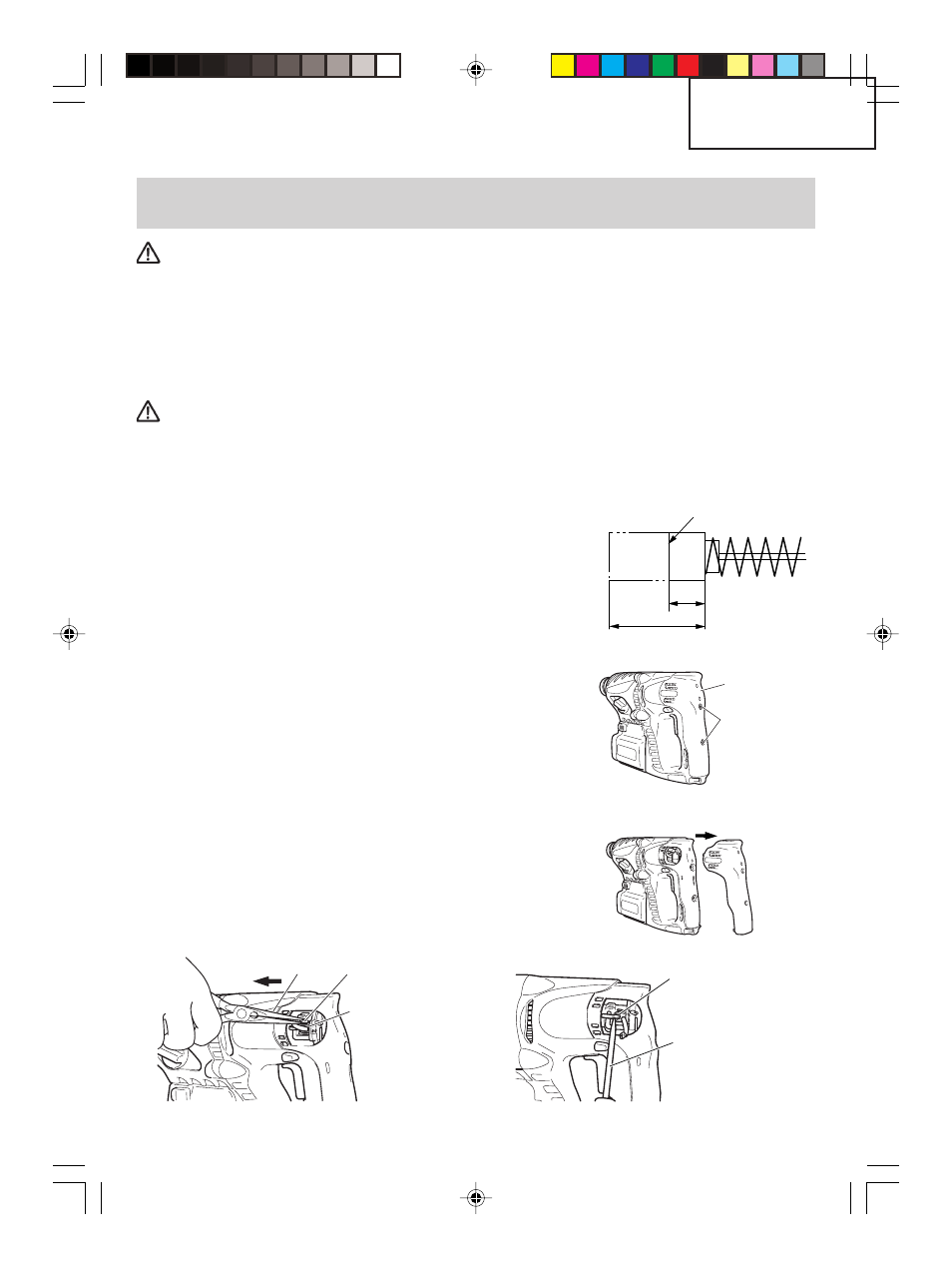

4. Inspecting the carbon brushes (Fig. 20)

The motor employs carbon brushes which are

consumable parts. When they become worn to or

near “wear limit”, it could result in motor trouble.

When an auto-stop carbon brush is equipped, the

motor will stop automatically. At that time, replace

both carbon brushes with new ones which have

the same carbon brush No. shown in the figure.

In addition, always keep carbon brushes clean and

ensure that they slide freely within the brush

holders.

5. Replacing the carbon brushes

(1) Loosen the screws (2) for the chuck cover, then

remove the chuck cover from the housing. (Fig.

21, Fig. 22)

(2) Pinch the terminals for the carbon brushes with

pliers, then pull them out of the brush holder. (Fig.

23)

(3) Pull the springs forward with a slotted screwdriver,

then remove the carbon brushes. (Fig. 24)

(4) Reverse these procedures to install the brushes.

Fig. 20

Fig. 23

Fig. 24

0.45"

(11.5 mm)

0.12" (3 mm)

Wear limit

Grip cover

Fig. 21

Screw

Fig. 22

Pull

Pull

Terminal

Carbon brush

Pliers

Spring

Slotted

screwdriver

01e_dh24dv_e.p65 copy

4/13/04, 11:29 PM

23