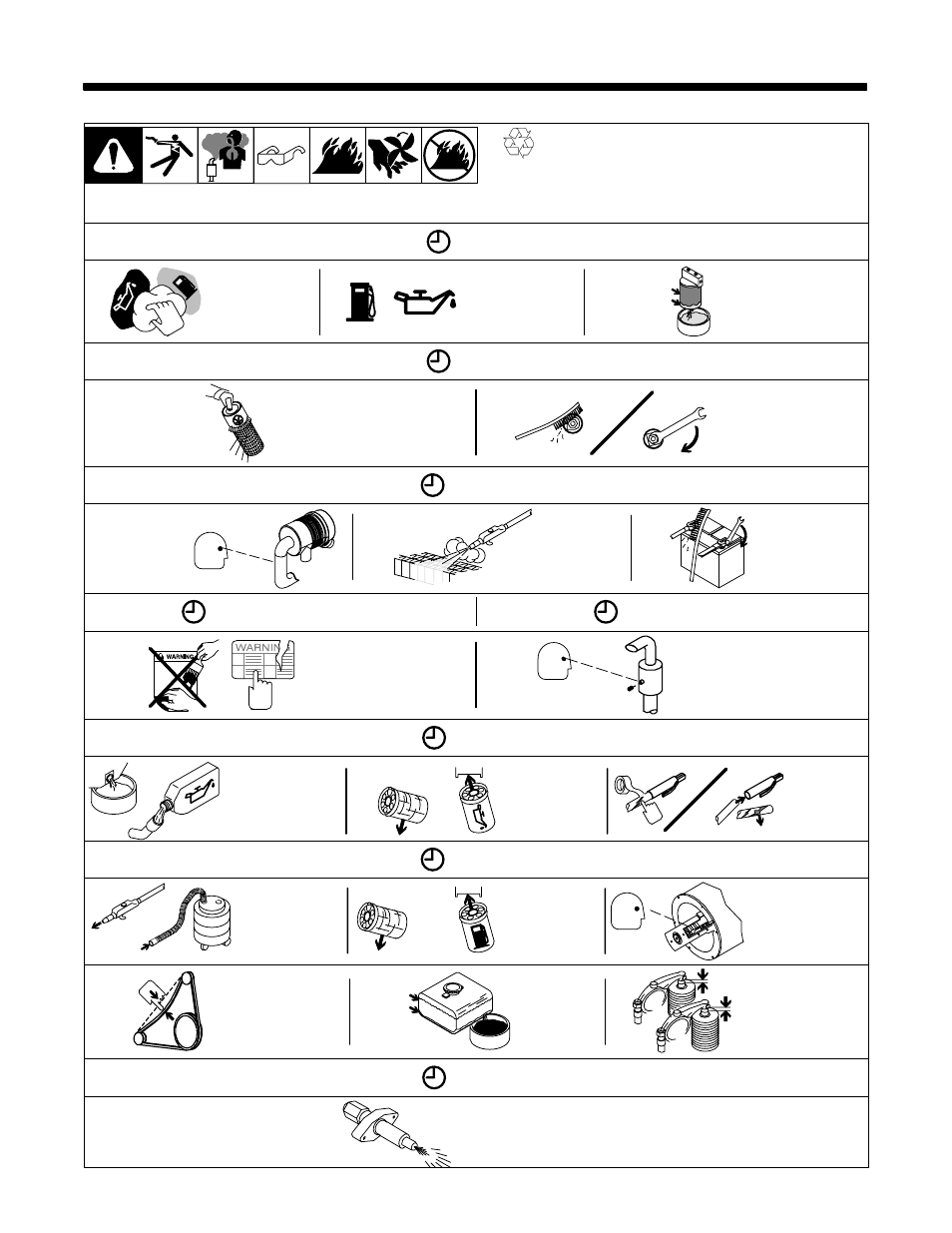

1. routine maintenance, 50 h, 100 h – Hobart Welding Products CONTRACTOR 3225D User Manual

Page 28: 500 h, 1000 h, 3000 h

OM-480 Page 24

SECTION 7 – MAINTENANCE AND TROUBLESHOOTING

7-1.

Routine Maintenance

Recycle

engine

fluids.

Y

Stop engine before maintaining.

.

See also Engine Manual and Maintenance Label.

Service engine more often if used in severe condi-

tions.

*

To be done by Factory Authorized Service Agent.

8 h

Wipe Up

Spills.

Check Fluid

Levels. See

Section 4-4.

Drain Water

From Fuel

System. See

Section 7-4.

FUEL

WATER

50 h

Clean Air Filter.

See Section 7-3.

Clean And

Tighten Weld

Terminals.

100 h

Clean

Cooling

System.

Clean And

Tighten

Battery

Connections.

Check air

cleaner hoses

for cracks and

loose clamps.

200 h

250 h

Replace

Unreadable

Labels.

Check And

Clean Spark

Arrestor. See

Section 7-8.

500 h

Change Oil. See

Section 7-4.

Change Oil

Filter. See

Section 7-4.

Repair Or

Replace

Cracked

Cables.

1000 h

Blow Out Or

Vacuum Inside.

During Heavy

Service,

Clean Monthly.

OR

Change Fuel

Filters. See

Section 7-4.

Service Welding

Generator Brushes

And Slip Rings.

Service More Often

In Dirty Conditions.*

1/2 in.

(13 mm)

Check

Belt

Tension.

Drain Sludge

From Fuel

Tank. See

Section 7-4.

FUEL

SLUDGE

Check

Valve

Clearance.*

3000 h

Clean/Set

Injectors.*