3. connecting optional auxiliary power plant – Hobart Welding Products CONTRACTOR 3225D User Manual

Page 26

OM-480 Page 22

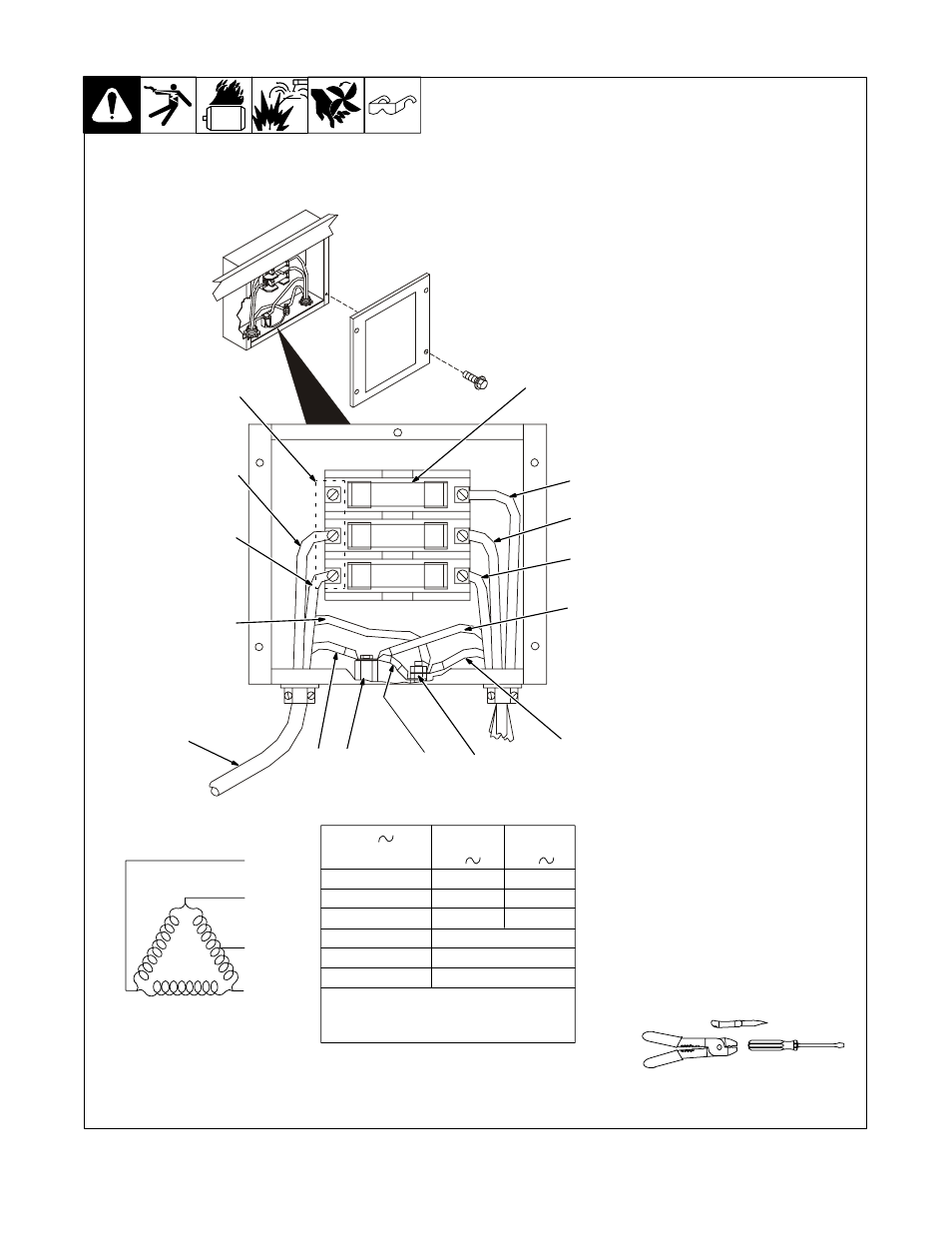

6-3.

Connecting Optional Auxiliary Power Plant

Ref. S-179 637-B

Y

Stop engine.

Y

Power and weld outputs are

live at the same time.

Disconnect or insulate

unused cables.

.

Have qualified person install

according to circuit diagram

and Auxiliary Power Guidelines

(Section 10).

Remove junction box cover.

1

Lead 93

2

Lead 92

3

Lead 91

4

Lead 90 (Neutral)

5

Lead 42 (Circuit Grounding

Lead)

Lead 42 connects to front panel

Ground stud.

6

Grounding Terminal

7

Jumper Lead 42

8

Isolated Neutral Terminal

Jumper 42 is connected to lead 90

at factory. Jumper 42 may be dis-

connected from neutral to meet

applicable electrical codes.

9

Lead 80

10 Receptacle RC9 leads

11 Lead 42

12 Lead 81

13 Lead 82

14 Load Terminals

Connect leads to terminals.

15 Fuses F1, F2, And F3

F1, F2, and F3 protect each load line

from overload.

.

Set Engine Control switch to

Run when using auxiliary

power.

92

90

91

93

Tools Needed:

F3

F2

F1

3

5

4

6

7

8

14

15

Volts

Amps

KVA/KW

Single

120/240

31

7.5

Three

240

24

10

60 Hz

Frequency

Engine Speed

Max. Fuse Size

35 Amperes

1850 RPM

AC

Phase

1

Phase

3

Output

Lead 42 connects to GROUND stud on front of

unit.

Jumper 42 is connected to 90 at factory.

1

2

10

9

13

12

11