6. connecting to weld output terminals – Hobart Welding Products CONTRACTOR 3225D User Manual

Page 20

OM-480 Page 16

ether1 12/96 – ST-153 382-A / Ref. ST-188 448

Y

Stop engine.

Y

Improper handling or expo-

sure to ether can harm your

health. Follow manufactur-

er’s safety instructions on

cylinder.

Y

Do not use Ether Starting Aid

while engine is running.

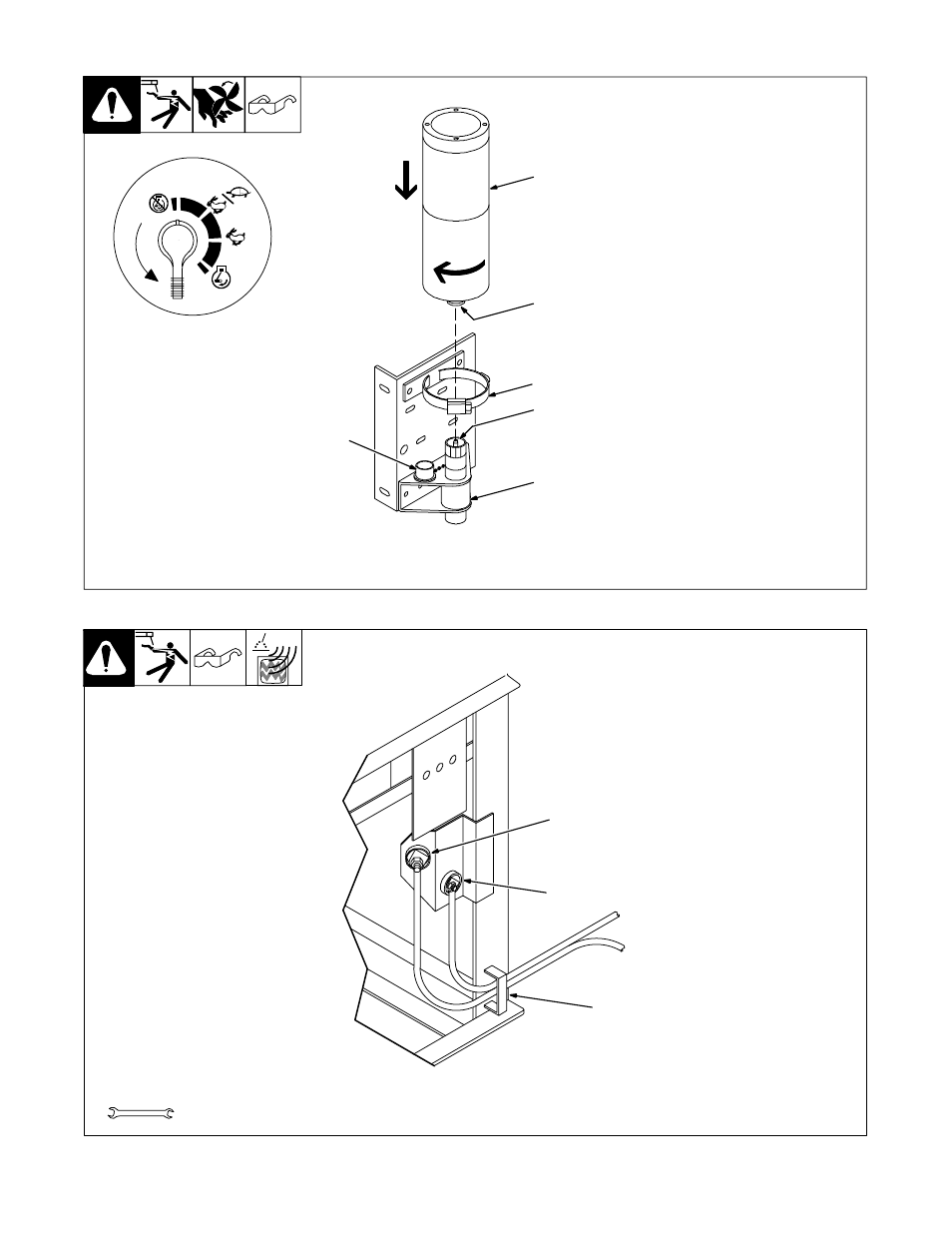

Open side door(s).

1

Ether Cylinder

2

Nozzle

Remove cover and clean cylinder

nozzle.

3

Clamp

4

Fitting

5

Cap

6

Valve

Remove cap and clean fitting.

Install cylinder on fitting. Tighten

clamp.

.

After installing cylinder, wait at

least 10 minutes before using

to let ether particles settle and

prevent atomizer plugging.

Put cap on fitting when cylinder is

removed.

1

2

3

4

6

5

4-5.

Installing Ether Cylinder (Optional Ether Starting Aid)

Ref. ST-800 162-A

Open left side door.

1

Bracket

Route cables through bracket.

2

Positive (+) Weld Output

Terminal

3

Negative (–) Weld Output Ter-

minal

For Stick welding Direct Current

Electrode Positive (DCEP), con-

nect work cable to (–) terminal and

electrode holder cable to (+)

terminal.

For Direct Current Electrode Nega-

tive (DCEN), reverse cable

connections.

If equipped with optional polarity

switch, connect electrode holder

cable to Electrode (–) terminal and

work cable to Work (+) terminal.

For FCAW welding, connect work

cable to (–) terminal and wire feeder

cable to (+) terminal.

Close door.

Tools Needed:

4-6.

Connecting To Weld Output Terminals

3/4 in

1

2

3