Hmr4007 – Honeywell HMR4007 User Manual

Page 6

HMR4007

SENSOR PRODUCTS

APPLICATION NOTES

USING THE HMR4007 AS A STAND ALONE SENSOR

Introduction

The HMR4007 can be used as a stand-alone sensor without the need for any digital communications. The board is

configured at the factory to provide a 0-2.5 VDC analog output (axial magnet) and status signal that represents the

position of the magnet along the long axis of the device. All power and signals are available on connector J2.

Connector J2 General Description

When used in a stand-along mode, only connector J2 needs to be used. Connector J2 is a 4-pin socket header that is

used to supply power (pin 1), ground (pin 4), analog position (pin 3), and status (pin 2). When power is supplied to

the board though J2, a jumper must be placed on pins 2-5 (center pair) in jumper block JP2. The power supply can

be regulated 5VDC or unregulated 6-28VDC. If connector J2 is used in combination with the communications port,

only ONE of the ports should be used to supply power to the board.

Analog Outputs

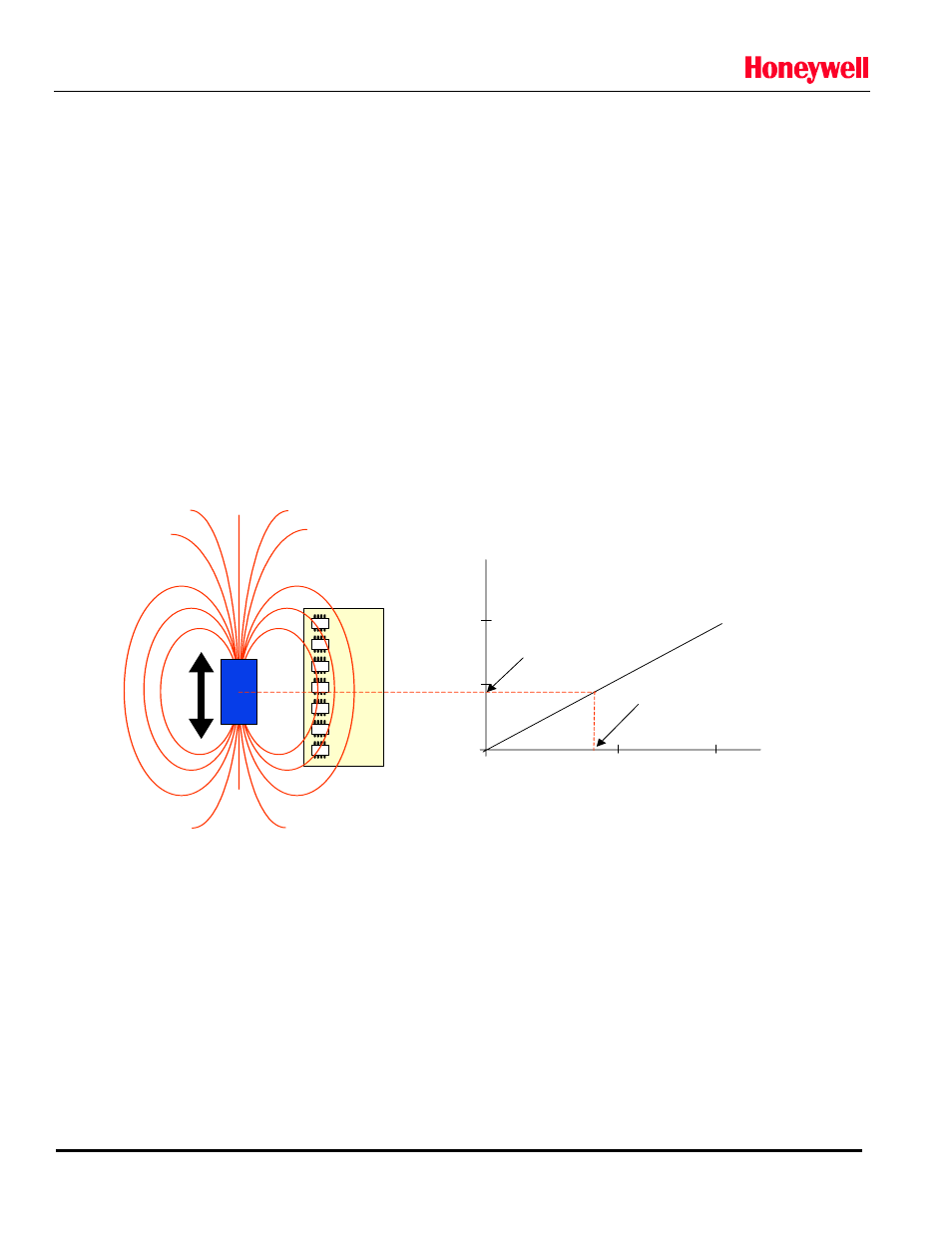

The analog output (J2, pin 3) represents the position of the magnet along the long axis of the sensor board as seen in

Figure 2 below. In the given example, the center of the magnet lies between sensors 3 and 4. The resulting output

voltage is 1.20 volts which corresponds to a position of 33.4 mm.

N

S

0

0

1 .2 5

2 .5 0

O u tp u t (v o lts, D C )

3 4 .8

6 9 .6

po

si

tio

n (

mm)

1 .2 0 v d c

3 3 .4 m m

Figure 2. Position sensing example.

An effort should be made to keep the angle of the magnet with respect to the sensor board reasonably constant along

the length of travel. The sensor, however, is quite tolerant to changes in distance (gap) between the sensor and

magnet along the length of travel.

Status Pin

Pin 2 (on port J2) is a TTL logic-level status output bit. This pin will be logic high (+5VDC) whenever the position

output is valid. Logic level low (ground) indicates that the sensor cannot calculate a magnet position. The most likely

causes of a position error signal are:

1. The magnet is beyond the sensed range of the device.

2. The magnet is too short or too weak for the sensors to track.

3. The gap between the sensor and magnet is too large.

4. The magnet is not present.

Solid State Electronics Center

•

www.magneticsensors.com

•

(800) 323-8295

•

Page 6