Hmr4007, Introduction – Honeywell HMR4007 User Manual

Page 2

HMR4007

SENSOR PRODUCTS

INTRODUCTION

The Honeywell HMR4007 is an electronic linear position sensing solution for use in commercial and industrial

application environments. A stationary array of Honeywell’s magnetoresistive (MR) sensors is utilized to quickly and

accurately monitor the position of a small magnet attached to a moving object such as a valve stem or hydraulic

cylinder. The use of a sensor array makes the solution highly insensitive to many environmental influences such as

magnet strength, alignment, run out, and temperature. This solution is easily integrated into systems using a highly

reliable serial interface or a 12-bit analog output (with over-range error indication).

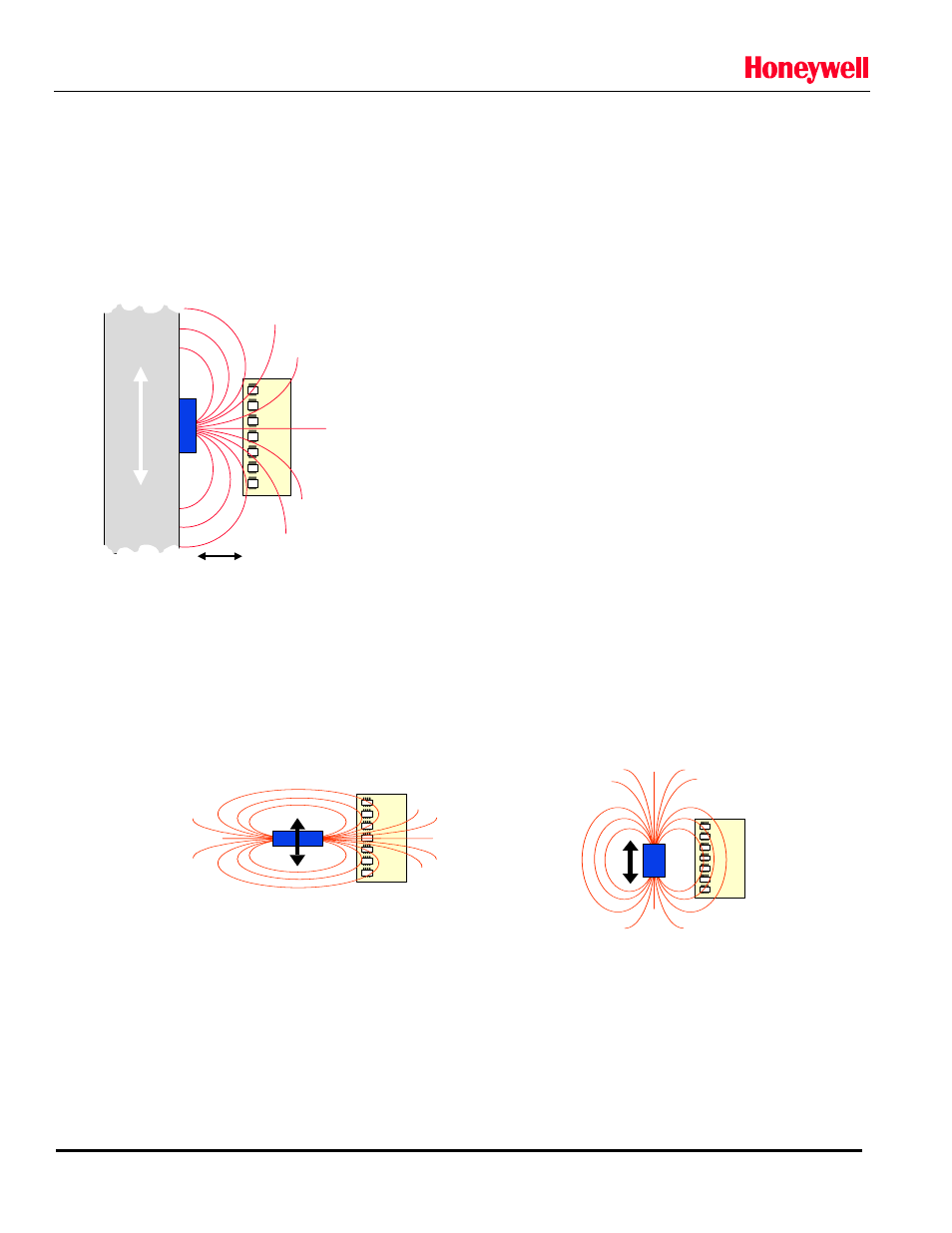

In normal operation, a small target magnet is mounted to the

moving object whose position is to be monitored and the sensor

array is held stationary. The exact standoff distance (gap) is

arbitrary (between 1/2” to 1-1/2”) as the embedded software is

highly tolerant of this gap. The sensed axis is parallel to the long

axis of the sensor board. The embedded software then

calculates the position of the magnetic center of the target

magnet as a function of its distance along the axis of the board.

The result is expressed as a 12-bit unsigned integer (or as a 12-

bit analog voltage). In the example to the left, if the center of the

magnet was aligned with the center of the bottom-most sensor in

the array, the result would be interpreted as a position of “0” while

alignment with the top-most sensor would be interpreted as a

position of “4095”. To convert the reading to engineering units,

the reported position is divided by 4095 and then multiplied by the

span of the sensors (69.7mm or 2.75”). If we call the reported

position “x”, then the position in engineering units would be:

N

~0.5 - 1.5”

moving object

stationary sensor card

Position in mm = (x / 4095) * 69.6

Position in inches = (x / 4095) * 2.75

The above example shows a magnet oriented in what is called the “radial” mode, where the magnetic poles point

towards the sensor card. The embedded software is also capable of operating with a magnet oriented in the axial

mode where the magnet poles point along the axis of the sensor as seen below. The sensor card, however, does

not automatically detect the magnet mode, and a status bit in the embedded code must be set to configure the

HMR4007. Software tools are available from Honeywell to easily accomplish this.

Radial mode magnet

“Axial” mode magnet

N

S

N

S

The orientation of the north and south poles is arbitrary, and the embedded software is highly tolerant of the magnet

geometry so that rectangular bar magnets or cylindrical magnets can be used equally well. Cylindrical magnets in

the axial mode are particularly attractive because the magnetic field is symmetrical with respect to rotation about the

center axis without loss of position accuracy.

The magnet should have a minimum length of 23mm (0.91 inches) along the axis of the travel. Shorter magnets,

however, can be used with some increase in the minimum gap between the magnet and sensor board as long as a

minimum field strength of 80 gauss and an apparent magnet length of 23 mm is maintained at the sensor board.

More on apparent magnet length can be found in the application notes at the end of this document.

Solid State Electronics Center

•

www.magneticsensors.com

•

(800) 323-8295

•

Page 2