Installation – Enviro WINDSOR 50-1578 User Manual

Page 12

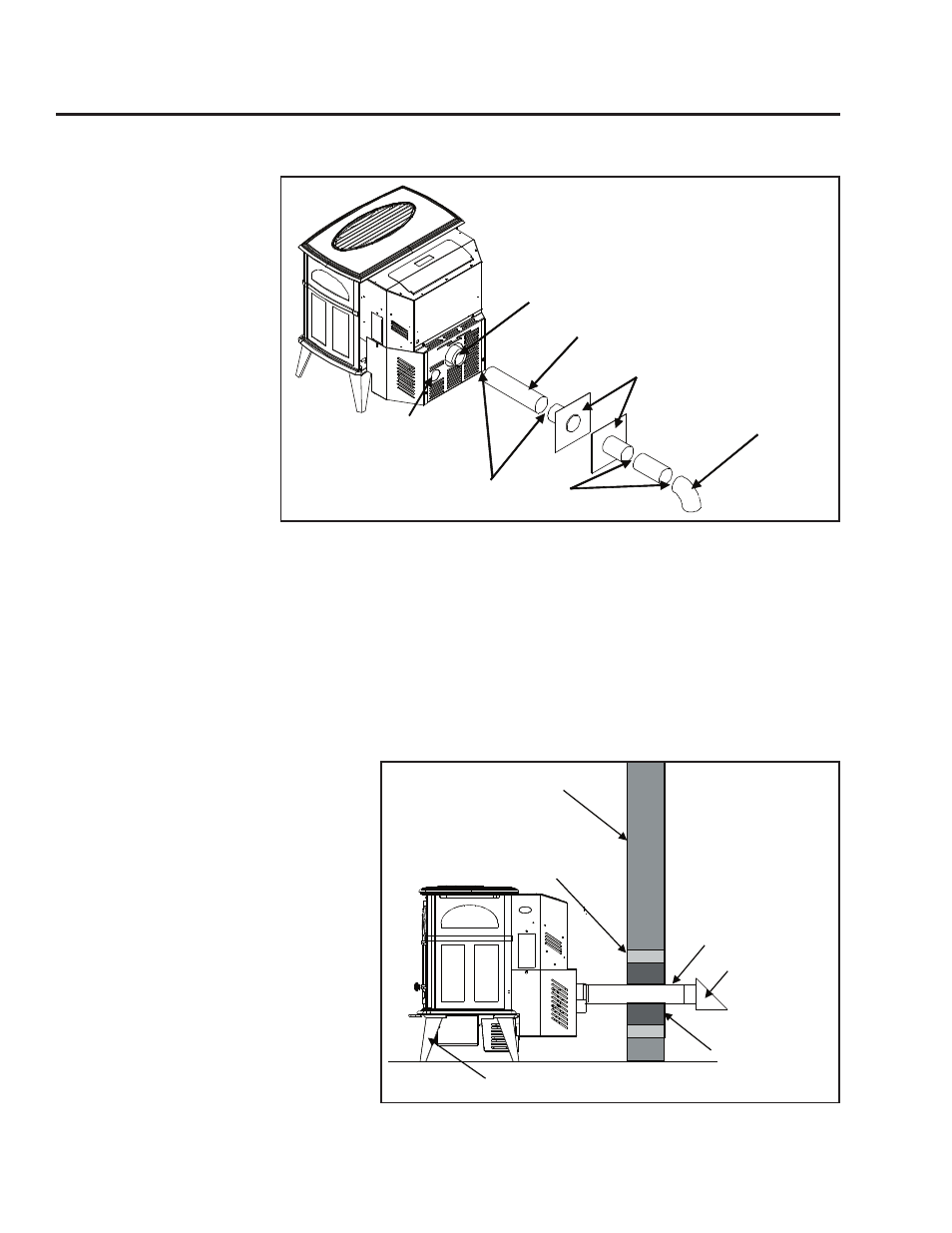

Exhaust

80mm (3") or 100mm (4")

Vent Pipe

Wall Thimble

45

o

Elbow with Screen

or Termination Cap

High Temperature RTV

Silicone Required

Fresh Air Intake

Wall framing

Wall thimble

Termination cap

Vent pipe

Horizontal frame

for thimble

������ �������

• This may be required if a proper burn

cannot be maintained, after the stove

has been tested and the airflow set.

• This is due to the back pressure in the

exhaust caused by airflow around the

structure.

• All sections of pipe must have three (3)

screws evenly spaced and all horizontal

and vertical vent sections located within

the house must have a bead of high

temperature silicone installed on the

male end of the pipe before installation

to create a gas tight seal.

Installation

Figure 9: Straight through wall Installation.

9. Push the stove straight

back, leaving a minimum

of 100mm (4”) clearance

from the back of the

stove to the wall. Seal the

vent pipe to the thimble

with high temperature

silicone.

10. The pipe must extend at

least 30 cm (12”) away

from the building. If

necessary, bring another

length of pipe to the

outside of the home

to connect to the first

section. Do not forget to

place high temperature

silicone around the pipe

that passes through the thimble.

11. Install a vertical pipe, or if all requirements for direct venting are met, install vent termination. The

stainless steel cap termination manufactured by the vent manufacturer is recommended. However,

when the vent terminates several feet above ground level and there are no trees, plants, etc. within

several feet, a 45° elbow can be used as termination. The elbow must be turned down to prevent

rain from entering.

NOTE:

• Some horizontal through wall installations may require a “T” and 91 to 152 cm (3 to 5 feet) of vertical

pipe outside the building to help naturally draft in the unit.

Figure 10: Straight through Wall Installation - Side View.

12