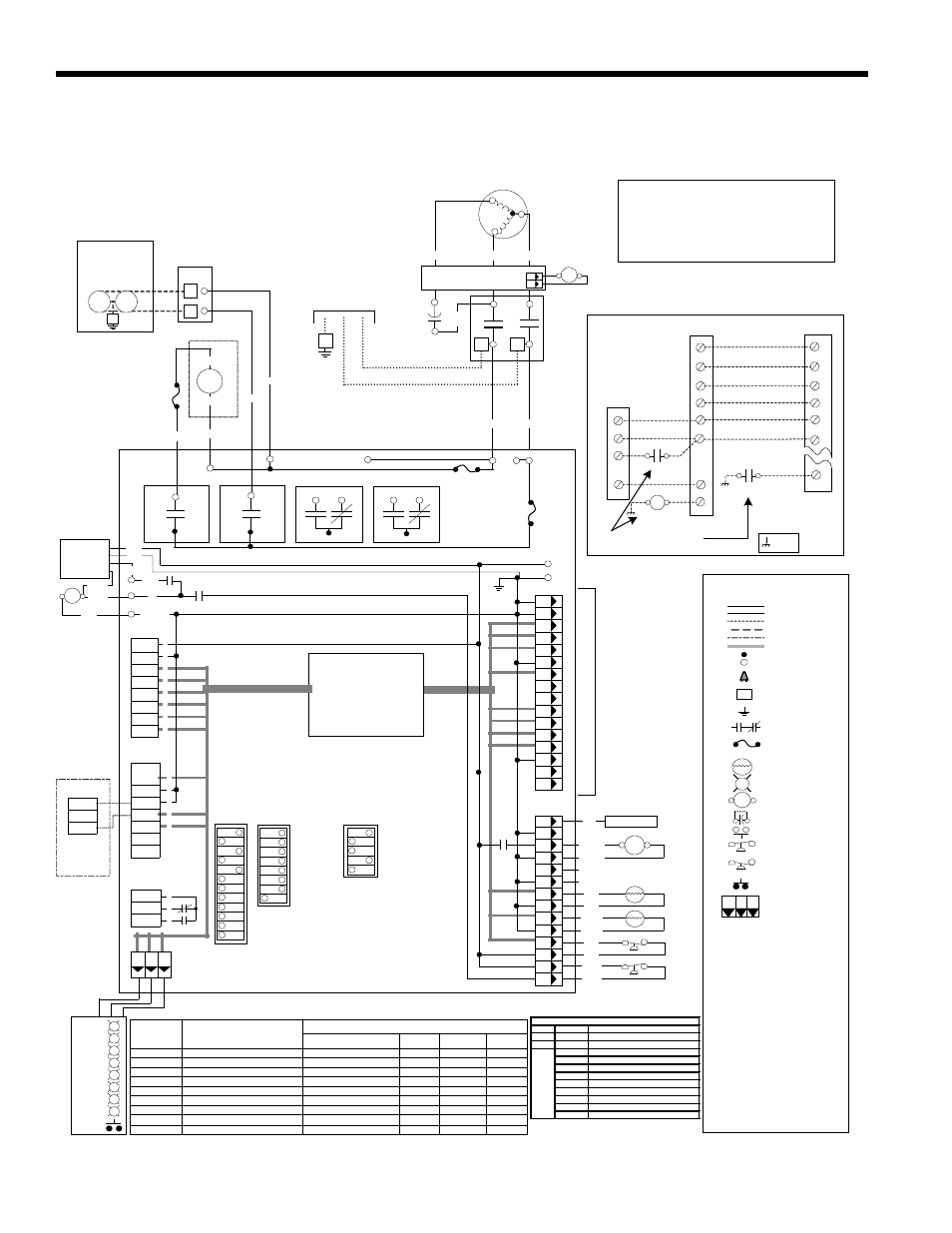

Wiring schematics, Envision series installation manual, Legend – Envision Peripherals Geothermal Indoor Split Heat Pumps User Manual

Page 16: Comfort alert

16

ENVISION SERIES INSTALLATION MANUAL

Wiring Schematics

Envision Series - Dual Capacity Split Wiring Schematic - 208-230/60/1

HWL

HP

LP

WCL

97P774-31 3/9/07

St

at

us

LE

D

PC

B

SW4

R

R

R

R

R

G

Y

R

T

T

240V L2

240V L1

240V L2

P6

Premier 2

Microprocessor

Logic Control

(DC Voltage)

P1

Fused L2

R

C

CC-GND

NO

CR2

COM

F1-10A 240V

Fused L2

NO

CR1

COM

1

2

3

4

5

6

7

8

1

2

3

P4

Pink

Black

Blue

Orange

Orange

Pink

Yellow

Yellow

1

2

3

C

P2

Down

C

1

2

3

4

5

6

7

Shut

SL1 In

Not

SL1 Out

Used

NOTE 1

Acc Com

Acc NC

Acc NO

1

2

3

P3

1

2

3

Main Logic PCB

F1-10A

240V

Tan

6

5

4

8

7

P5

12

1

2

9

10

3

4

9

11

2

10

8

1

12

5

3

13

14

15

16

11

G

W

O

R

C

Y1

Y2

LO

On

SW1

1

2

3

4

5

6

7

8

9

10

11

12

ECM2

Air Flow

Settings

Black

Blue

14

13

6

7

CC

NO

NC

CR4

COM

NO

NC

CR3

COM

RV

CCHI

Not Used

Not Used

On

SW3

On

SW2

1

2

3

4

5

6

7

8

No Htg3 / Htg3

Dehum / Norm

Fan / Comp

Loop / Well

Test / Norm

Outputs / Norm

Inputs / Norm

2 Speed / 1 Speed

Normal / Finish on 2

nd

(Note 2)

No RPM / RPM

Electric Heat / Normal

Envision / E Series or Premier

1

2

3

4

5

Pulse L / Constant L (NOTE 4)

Field Selection Dips - #1 On, #6 On, #7 On

Drain pan overflow Lockout

FP thermistor (loop<15°F,well<30°F) Lockout

High Pressure > 600 PSI Lockout

Low Pressure < 40 PSI Lockout

ECM2 RPM < 100 rpm Lockout

Microprocessor malfunction*

HWL thermistor > 130°F

DHW pump switch off

Drain

Water Flow

High Press

Low Press / Comp

Air Flow

Status

DHW Limit

DHW off

LED

Normal Display Mode

#1 Off, #6 On, #7 On

Drain pan overflow

FP thermistor (loop<15°F, well<30°F)

High Pressure > 600 PSI

Low Pressure < 40 PSI

ECM2 RPM < 100 rpm

Not Used

HWL thermistor > 130°F

DHW pump switch off

Current Fault Status

#6 Off, #7 On

Y1

Y2

O

G

W

SL1

SL2

--

Inputs

#6 On, #7 Off

Compressor Lo

Compressor Hi

RV

FAN

DHW Pump

Loop Pump 1

Loop Pump 2

--

Outputs

#6 Off, #7 Off

Blower Lo

Blower Med

Blower Hi

Aux Heat #1

Aux Heat #2

AuxHeat #3

Aux Heat #4

--

Outputs2

Diagnostic Modes

*Green LED not flashing

Thermistor

Light emitting diode - Green

Relay coil

Capacitor w/ bleed resistor

Switch - Condensate overflow

Switch - High pressure

Switch - Low pressure

Switch -Hot Water On/Off

Polarized connector

Factory Low voltage wiring

Factory Line voltage wiring

Field low voltage wiring

Field line voltage wiring

Optional block

DC Voltage PCB traces

Internal junction

Quick connect terminal

Wire nut

Field wire lug

Ground

Fuse

CC -

CO -

CR1 -

CR2-

CR3 -

CR4 -

F1 and F2 -

WCL -

HE -

HP -

LP -

PB1, PB2 -

PS -

RV -

SW1 -

SW2 -

SW3 -

SW4 -

TS -

Compressor Contactor

Condensate overflow sensor

DHW pump relay

Loop pump relay

Fuses

Water Coil Limit Sensor

Heater element

High pressure switch

Low pressure switch

Power blocks

Power strip

Reversing Valve coil

DIP package 12 position

DIP package 8 position

DIP package 5 position

Hot water pump enable switch

Thermal limit switch

Legend

Relay Contacts-

N.O., N.C.

G

T

1

3

2

P

L1

PSC Fan Speed Relay

PSC Fan Power Relay

ER1 to ER4 -

Aux heat stage relays

HWL -

Hot water limit sensor

SC -

Start Contactor

Start Relay

SR -

CS -

Compressor Solenoid **DC Coil**

CA -

Comfort Alert

Y1

Y2

O

R

C

L

C

R

Fossil Fuel

Furnace

Thermostat

24 VAC

Common

Common

24 VAC

Fault Signal

Reversing Valve

2nd Stage Compressor

1st Stage Compressor

Y1

Y2

O

R

C

LO

Envision Split

G

G

Fan

W

W

Auxiliary Heat Relay

Duel Fuel Wiring Diagram

Using Field Installed Relay

Note: Field installed DPST dual fuel relay

(Required for dual fuel installation)

Auxiliary Heat Relay

P2

P1

Shut

Auxiliary

Heat Relay

Down

= chassis

LED

Flash Code Description

Green

Solid

Module Has Power

Red

Solid

Y1 Present But Compressor Not Running

Code 1

Long Run Time

Code 2

System Pressure Trip

Code 3

Short Cycling

Code 4

Locked Rotor

Code 5

Open Circuit

Code 6

Open Start Circuit

Code 7

Open Run Circuit

Code 8

Welded Contactor

Code 9

Low Voltage

Yellow

Comfort Alert Status

N

O

T

U

S

E

D

NOTE 5

DHW

Pump

Blu

3A

Fuse

Pink

Blu(17)

Ext Pump

1/2 hp Total

208-230/60/1

Pump

Pump

G

2

1

PB1

1

2

Yel(8)

Pink(13)

Unit Power

208-230/60/1

G

L2

L1

CC

C

S

R

Run

Capacitor

Red

Black

Blue

Tan

(16)

Comfort Alert

CC

Blk(1)

Violet(2)

Comfort

Alert

R

Y

C

Violet(3)

Blk(5)

Yel(6)

L

Comfort Alert

NOTE 3

CS

+

-

DC SOL

Wht(4)

Brn(15)

Org(14)

Gry(9)

C

NOTE 6

SL1 In

SL1 Out

Optional

Remote Unit

Without

Loop Pump

Y2

Notes:

1 - 24V Accessory relay (see SW2 - 3 for description of operation )

4 – SW2-8 must be in the OFF position for pulsed “L” lockout signal and in the ON position for constant

“L” lockout signal.

2 – This Switch allows the unit to down stage with the t -stat when OFF and finish on second stage when

ON. Finish second stage reduces stage changing in recip dual capacity compressors and should

be ON for unzoned Dual Cap E -Series or Premier 2 speed units.

5 - DHW pump only in models with hot water generation option .

6 - Connection of remote unit that does not have a loop pump for slave operation .

3 - Comfort Alert fault output to Premier Control Board