Exide Technologies PORTFOLIO PAR20 User Manual

Page 15

Apply a thin film of NO-OX-ID “A” grease (supplied) to all

terminal surfaces, bolts, and washers. This will

preclude oxidation after connections are completed.

9.1

Connections - System Terminals

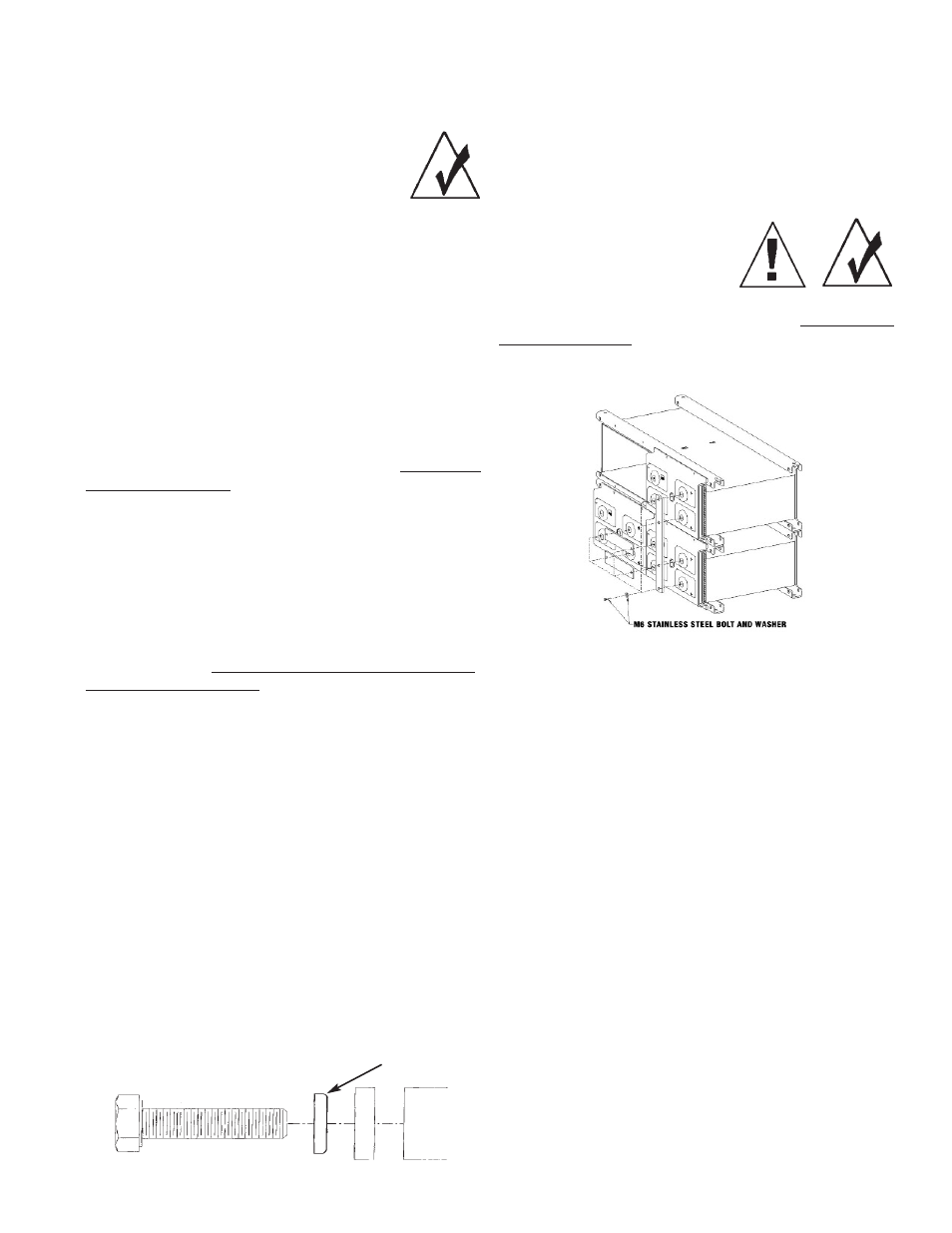

Each system is supplied with a terminal plate

assembly for the positive and negative termi-

nations. These should always be used to provide proper

connection to the operating equipment and cell terminals.

Any attempt to connect load cables directly to cell termi-

nal may compromise battery system performance as well

as the integrity of cell post seals.

Refer to layout/wiring diagram for location of terminal plate

assembly in your battery configuration. Assemble Terminal

Support Bracket to module channel using hardware indi-

cated, items 3, 4, 5, 6. Hardware will be located in a bag

labeled K17-417240P for top termination or K17417256 for

side termination. Assemble Terminal Plate to Support

Bracket and battery posts. Hardware to attach to Support

bracket is also located in the terminal plate kit. It is recom-

mended that all connections be torqued to 11 Newton-

meters (100 in-Lbs). After making cable connections,

assemble Terminal Plate Covers, Items 7 & 8, to the Terminal

Support Bracket using hardware indicated. Hardware to

assemble Terminal Plate Covers will be located in the ter-

minal plate kit. Refer to Sections 9.0 and 9.2 for electrical

contact surface preparation of terminal plate components.

Terminal plate assembly varies with termination location.

Refer to layout/wiring diagram termination location on

your battery. Figure 20 shows top termination assembly

with instructions. Do not make connections to operat-

ing system at this time.

9.2

Connections - Inter-MODULE

Consult layout/wiring diagram for correct quantity of lead-

tin plated copper connectors required for each

connection. Follow procedure in Section 9.0 and brighten

lead-tin plated surfaces coming in contact with copper

posts. Apply a thin film of NO-OX-ID “A” grease to these

areas.

NOTE: Apply a minimum amount of grease to cover the

surface. As a rule: "If you can see it, it's too much".

Where multiple connectors are required across any single

connection, brighten both sides of connectors along the

entire length. Grease these areas as well. It is recom-

mended when installing connectors on horizontal

arrangements that the upper bolts be installed first to

reduce risk of accidental shorting.

Refer to layout/wiring diagram for connector placement

and materials list. Figure 19 shows typical module

connections, intrastack connections and interstack

connections.

9.3

Connections - Inter-STACK

Multiple stacks end to end are interconnected as shown in

layout/wiring diagram. Follow the procedures in Sections

9.1 and 9.3.

9.4

Torquing

When all inter-module and inter-stack connections have

been installed, tighten all connections to 11.3 Newton-

meters (100 in-Lbs) Use insulated tools. Recheck connec-

tions after the initial charge due to heating during charge.

STACK CONNECTIONS

Figure 19

9.5

Connection - Check

Again, visually check to see that all module terminals are

connected positive (+) to negative (-) throughout the

battery. Positive terminals have red cap. Negative

terminals have black cap.

Also measure the total open circuit voltage from terminal

plate to terminal plate. This should be approximately

equal to 2.14 volts times the number of cells in the

system, e.g., a 24 cell system would read:

24 x 2.14v = 51.4 volts. An incorrect voltage reading may

mean connectors were installed incorrectly.

SECTION 10: IDENTIFICATION LABELS

10.0

Surfaces

Make sure surfaces are free of dirt and grease by wiping

with clean, dry wipers (isopropyl alcohol may be used) to

ensure proper label adhesion.

10.1

Cell Numerals

A set of pressure sensitive cell numerals and system

polarity labels are supplied and should be applied at this time.

Cell numerals should be applied to the cell being identified.

Designate the positive terminal cell as #1 with succeeding

cells in series in ascending order.

WASHERS SHOULD BE INSTALLED WITH THE CURVED

EDGE TOWARD THE CONNECTORS.

BOLT

WASHER CONNECTOR

POST

15