Exide Technologies PORTFOLIO PAR20 User Manual

Page 14

INSTALLING

COMPLETED

HARDWARE

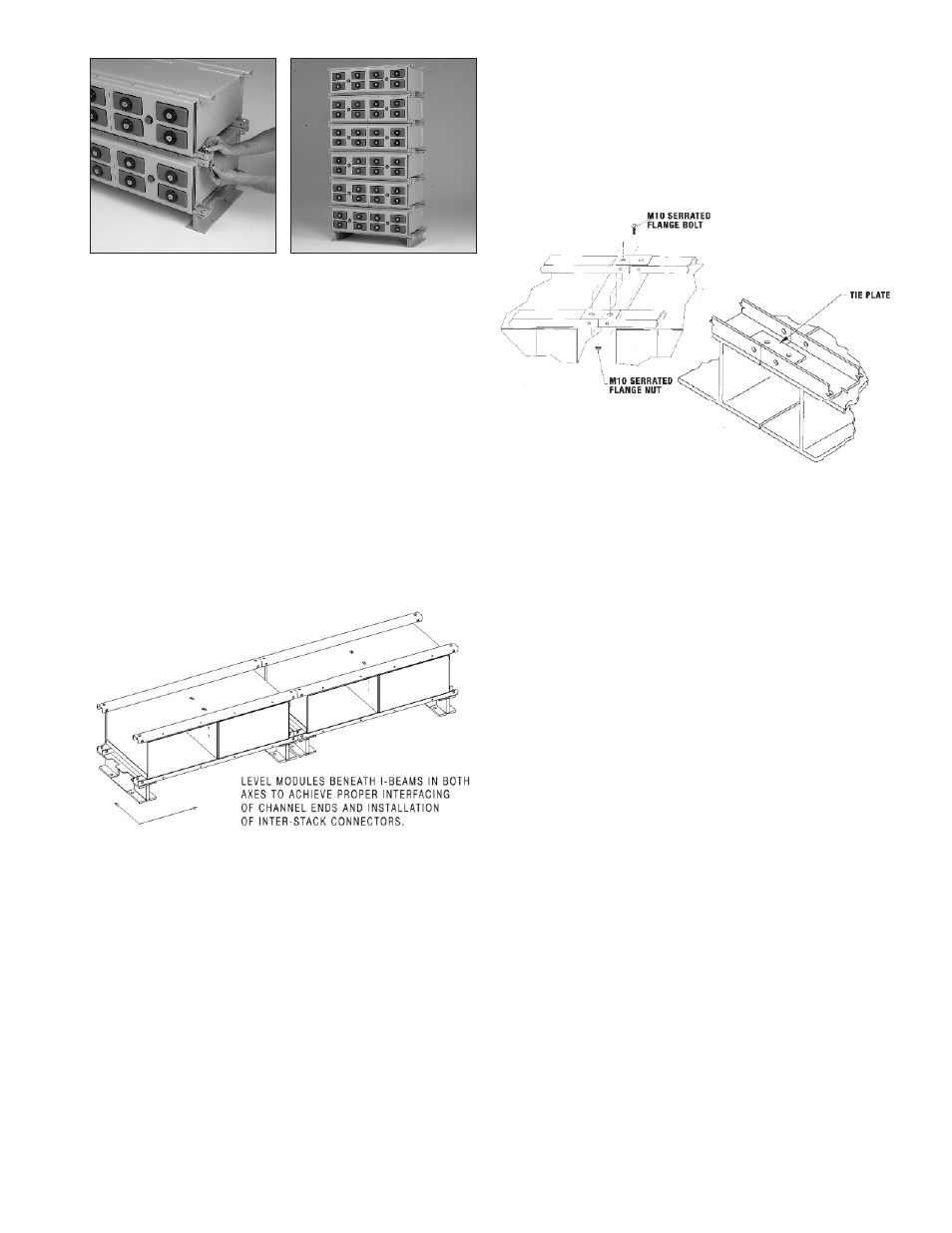

HORIZONTAL STACK

Figure 15

Figure 16

8.2

Horizontal-Multiple Stacks

8.2.1 Stacking Base Modules

It is recommended that all of the first modules with bottom

supports attached (see Section 8.1.1) be placed in position

first. A chalk line floor mark should be used to assure all

stacks will be in a straight line. This applies for stacks end-

to-end or end-to-end and back-to-back. Refer to Sections

6.5 and 8.1.3 for handling and tip over procedures.

For stacks end-to-end, module ends should be butted

together so that module side channel ends meet (see

Figure 17).

POSITIONING HORIZONTAL BASE MODULES

Figure 17

For stacks back-to-back, the two base modules are posi-

tioned to provide a minimum 4.5” spacing between the

bottoms of the modules (not I-beam edges). Refer back to

Figure 1.

Refer to layout/wiring diagram for seismic shim require-

ments.

8.2.2 Stack Tie Plates

At this time stack tie plates should be installed. It will be

necessary to temporarily remove the hardware fastening

the base modules to the I-beams.

To achieve maximum stack stability, especially where

seismic conditions may exist, as well as proper interfacing

of inter-stack connections, metal tie plates are provided.

The plates used on stacks end to end are 3” x 1” x 1/8”

with two 9/16” holes. Use one tie plate at each interface to

connect the module channels of adjacent stacks. See

Figure 18.

TIE PLATE ASSEMBLIES - HORIZONTAL STACKS

Figure 18

Position plates on the module channels and secure with

hardware as shown. Where stacks have different heights

(for example a 3 high stack adjacent to 4 high stack), install

plates on shorter stack top module and adjacent module.

Torque hardware to 47 Newton-meters (35 Ft-Lbs).

8.2.3 Horizontal Stacking

When all base modules are set in place, continue with

stacking of subsequent modules. Procedures for assem-

bly of multiple horizontal stacks are the same as outlined

in section 8.1.3. Also consult layout/wiring diagram. Each

stack should be built up in sequence to the same level

until the top modules in all stacks are the last to be

installed. The use of a line chord attached to upper mod-

ule corners of opposite end modules as stacking pro-

gresses aids in alignment.

This completes the mechanical assembly of the battery

system.

For installation of intermodular connections and terminal

plate assembly, see Section 9.

For installation of protective module cover, see Section 11.

SECTION 9: ELECTRICAL CONNECTIONS

9.0

Post Preparation

All cell posts were greased at the factory. Using either a

brass bristle suede shoe brush or 3M Scotch Brite scour-

ing pad, brighten the flat copper terminal surfaces to

ensure lowest resistance connections.

TOP MODULE

BASE MODULE

14