Exide Technologies PORTFOLIO PAR20 User Manual

Page 13

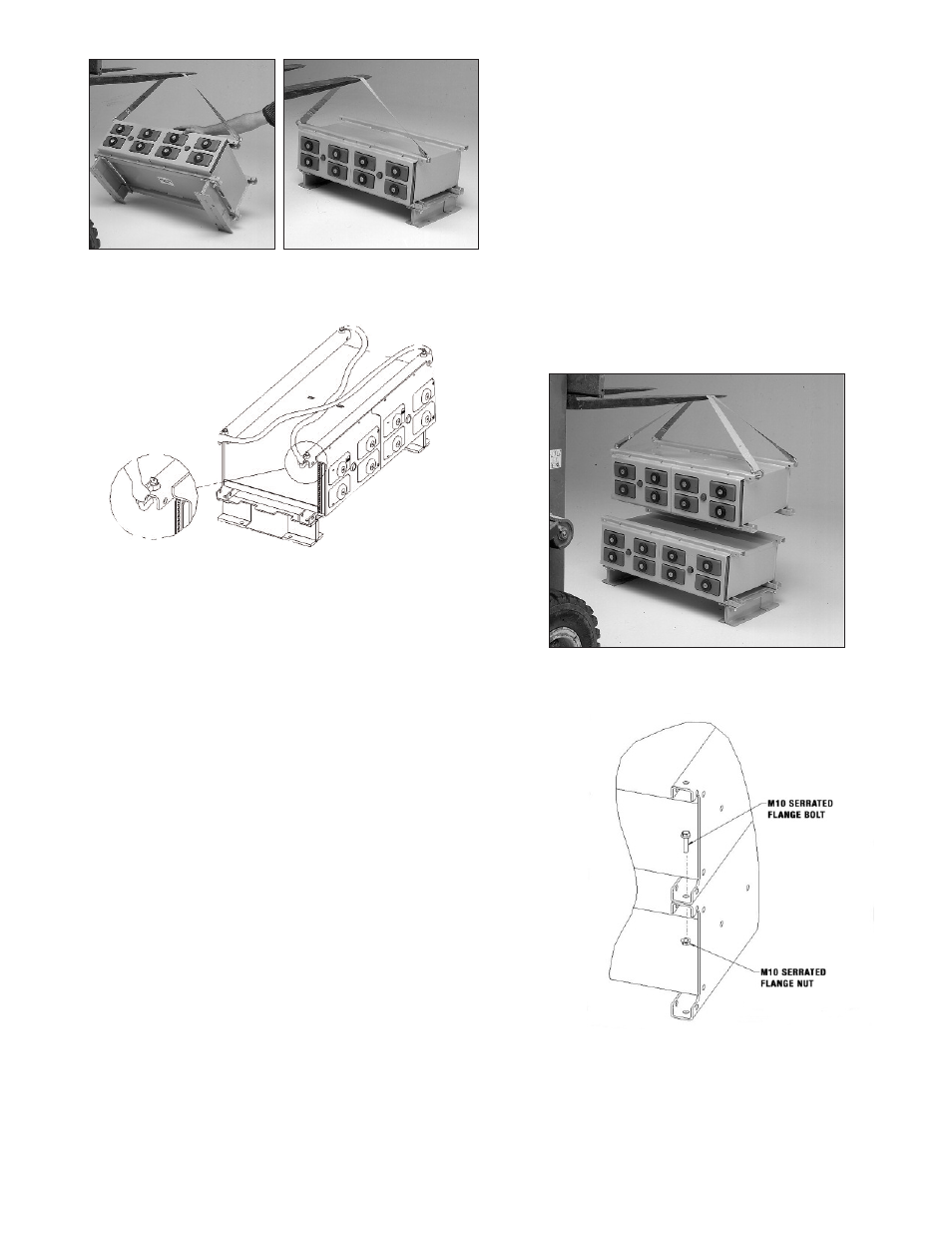

TIP-OVER PROCEDURE MODULE AFTER TIP-OVER

Figure 10

Figure 11

HORIZONTAL STACKING SHACKLE-STRAP USAGE

Figure 12

Where floor anchoring is required, position module/I-Beam

assembly in desired location. Mark floor through I-beam

holes and remove module/base assembly. Install floor

anchoring and reposition module/base assembly over

anchoring. Prior to installing nuts and washers, check that

assembly is level in both axes. Level using shims provid-

ed. When level, fasten assembly and torque nuts to 47

Newton-meters (35 Ft-Lbs).

In order to complete stacking of a horizontal single stack

refer to Figures 12 to 15 and steps A through C listed

below.

NOTE: The use of leveling shims is required when

assembling any Absolyte GX system in order to

meet seismic requirements. Failure to use the

shims to level each module and to fill spaces

between tray channels during module assembly

will result in the assembly not meeting seismic

certification criteria. In extreme cases, stack to

stack connectors cannot be installed.

A. Using Section 6.5 and 8.1.3 and the layout/wiring

diagram, position the next module on top of first so that

channels of each mate with one another. Use drift pins

to align channel holes. Make sure channel ends and

sides of the upper and lower modules are flush.

Remove lifting straps and install M10 serrated flange

bolts and nuts in open holes, finger tight. Use leveling

shims to fill gaps between trays. See Figures 13, 14

and 15.

B. At this time, check to see that the first two modules are

plumb front to back and side to side using wooden or

plastic level together with plywood straight edge. This

is to insure proper alignment for module interconnec-

tion later on. Torque hardware to 47 Newton-meters

(35 Ft-Lbs).

C. Proceed with stacking of remaining modules, checking

that stack is plumb in both axes as stacking progress-

es before torquing hardware. Be certain to check the

layout/wiring diagram for correct horizontal orientation

to provide proper polarity interconnection as stacking

progresses. See Figure 16 for completed assembly.

HANDLING AND STACKING HORIZONTAL MODULES

Figure 13

HARDWARE INSTALLATION SEQUENCE

Figure 14

13