Energizer PP355 User Manual

Page 4

P a g e

| 4

ENERGIZER BATTERY MANUFACTURING

VERSION 1.2

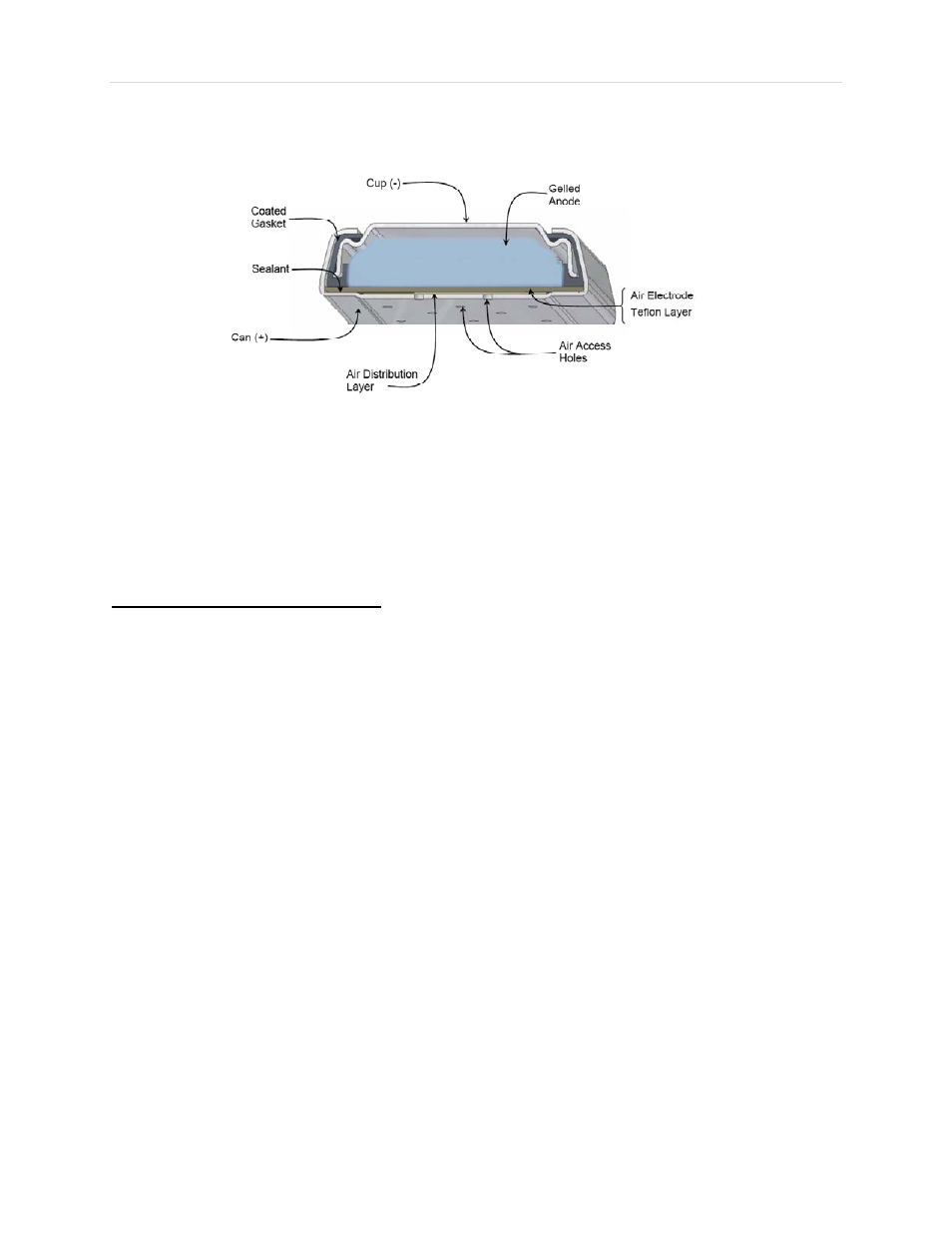

Figure 1: Cross Section View of Zinc Air Prismatic Battery

Energizer Zinc Air Prismatic batteries are designed to allow air to enter the air holes and to prevent the

transport of liquid electrolyte out of the battery. A gasket is used to seal between the anode cup and

the cathode can. The gasket also electrically insulates the negative cup from the positive can. An air

electrode and a loose layer of Teflon are compressed onto a band of sealant on the bottom of the can.

This Teflon layer allows gasses to enter the battery while preventing liquid from passing through.

1.3 ‐‐ Features of Zinc Air Prismatic

Energizer’s Zinc Air Prismatic batteries offer a 5 mm thin, prismatic construction designed to work with a

variety of applications. This shape is consistent with the low profile design of today’s devices, often

requiring a thinner battery solution. The thinnest round cell available is the AAAA battery at

approximately 8 mm, and many Lithium Ion rechargeable solutions have a thickness of 5 mm.

Energizer Zinc Air Prismatic batteries also offer the opportunity to significantly lower manufacturer

costs. It is likely that the cost of a Zinc Air Prismatic battery solution will be less than the cost of a

Lithium Ion battery. Adding to the cost of a Lithium Ion solution is the cost of circuitry for charge and

discharge control, which is not needed with Zinc Air Prismatic batteries. Furthermore Zinc Air Prismatic

batteries are ready to be used out of the package. There is no need for charge adaptors.

Energizer Zinc Air Prismatic batteries can last up to 3X longer than comparable volume battery systems.

This service advantage is due to Zinc Air technology offering the highest energy density for non‐

rechargeable and rechargeable consumer batteries. Figure 2 demonstrates this advantage over Alkaline

and Lithium Ion batteries of similar volume.