Dayton portable forced air heater, 3vg79b, Maintenance (continued) – Dayton 3VG79B User Manual

Page 8

Dayton Operating Instructions and Parts Manual

8

Dayton Portable

Forced Air Heater

®

3VG79B

Maintenance (Continued)

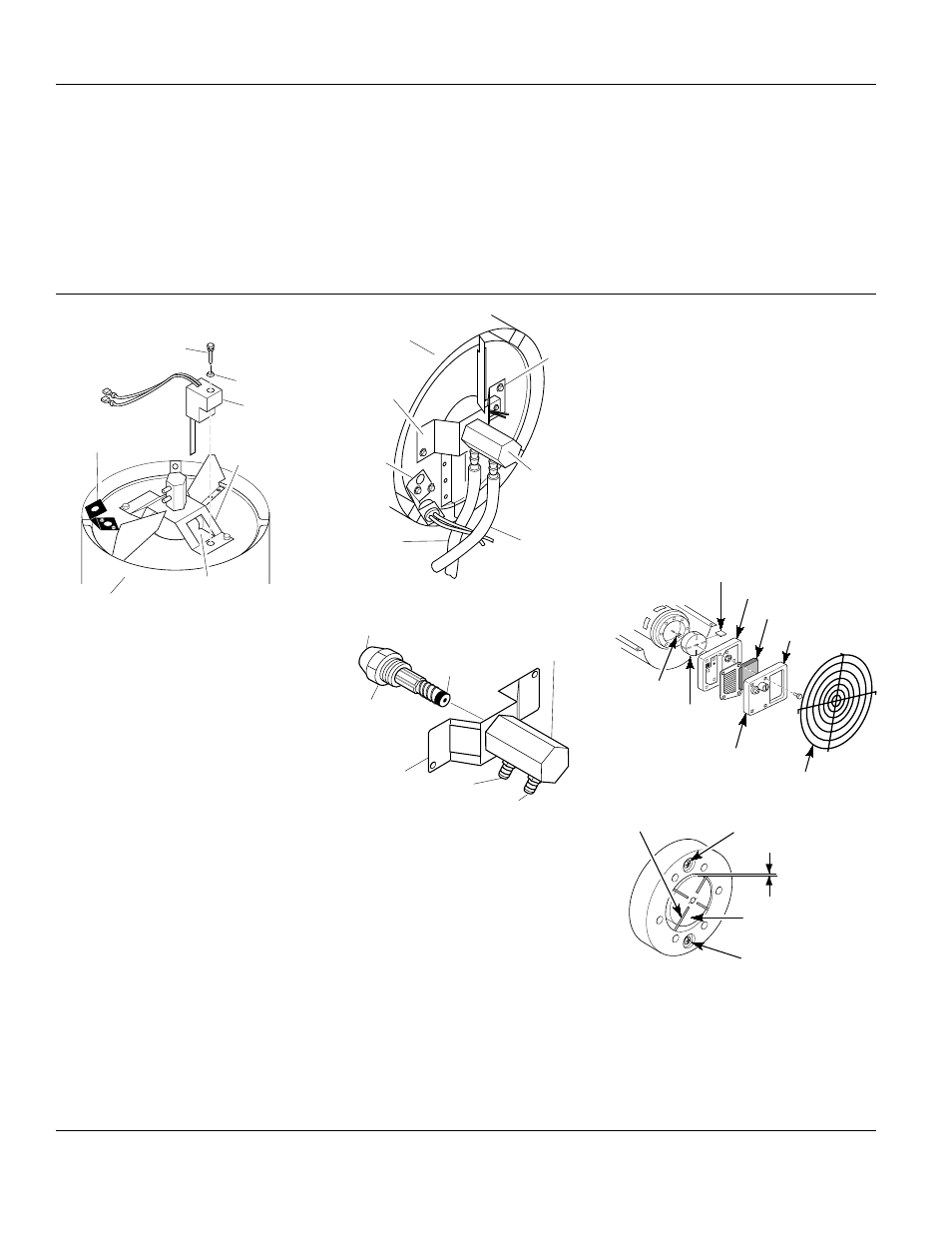

Figure 13 - Ignitor Replacement

Combustion

Chamber

Photocell

Bracket

Ignitor

Ignitor Screw

Nozzle

Adapter

Bracket

Nozzle Adapter

Bracket Opening

Ignitor

Element

Washer

NOZZLE ASSEMBLY

1. Remove combustion chamber and

ignitor by following steps 1 through 7

under Ignitor, page 7.

2. Carefully place the ignitor in a safe

location.

3. Remove two nozzle adapter bracket

screws (See Figure 14).

4. Place hex-shaped aluminum nozzle

adapter into vise (do not overtighten).

5. Carefully remove nozzle from nozzle

adapter using 5/8" socket wrench (See

Figure 15).

6. Blow compressed air through face of

nozzle. This will remove any debris in

nozzle.

7. Inspect nozzle seal for damage.

8. Replace nozzle into nozzle adapter

until nozzle seats. Tighten 80-110

inch-pounds.

9. Attach nozzle adapter bracket to

combustion chamber with two screws

removed in step 3.

10. Repeat steps 9 through 16 under

Ignitor, page 7.

Figure 14 - Removing Air and Fuel Line

Hoses

Combustion

Chamber

Nozzle

Adapter

Bracket

Nozzle

Adapter

Bracket

Screw

Fuel Line

Hose

Nozzle/

Adapter

Assembly

Photocell

Bracket

Air Line

Hose

Figure 15 - Nozzle and Nozzle Adapter

Nozzle Face

Nozzle

Nozzle

Seal

Nozzle

Adapter

Bracket

Air Line

Fitting Fuel Line

Fitting

Nozzle

Adapter

Fan Guard

Filter End Cover

Air Intake Filter

Pump Plate

Blade

Air Output Filter

Rotor

Insert

Gap Adjusting Screw

Gap Adjusting Screw

.003"/.004" Gap

Measured With

Feeler Gauge

Rotor

Blade

PUMP ROTOR

(Refer to Figure 16)

(Procedure if rotor is binding)

1. Remove upper shell (See page 5).

2. Remove filter end cover screws using

5/16" nut-driver.

3. Remove filter end cover and air filters.

4. Remove pump plate screws using 5/16"

nut-driver.

5. Remove pump plate.

6. Remove rotor, insert, and blades.

7. Check for debris in pump. If debris is

found, blow out with compressed air.

8. Install insert and rotor.

9. Check gap on rotor. Adjust to

.003"/.004" if needed (See Figure 17).

NOTE: Rotate rotor one full turn to insure

the gap is .003"/.004" at tightest position.

Adjust if needed.

10. Install blades, pump plate, air filters,

and filter end cover.

11. Replace fan guard and upper shell.

12. Adjust pump pressure (See page 6).

NOTE: If rotor is still binding, proceed as

follows.

Figure 16 - Rotor Location

Figure 17 - Gap Adjusting Screw Locations