Operating instructions, Unpacking and cleaning, Extension cords – Delta 36-841 User Manual

Page 5: Foreword

Use proper extension cords. Make sure your extension cord is in good condition and is a 3-wire extension cord which

has a 3-prong grounding type plug and matching receptacle which will accept the machine’s plug. When using an

extension cord, be sure to use one heavy enough to carry the current of the machine. An undersized cord will cause

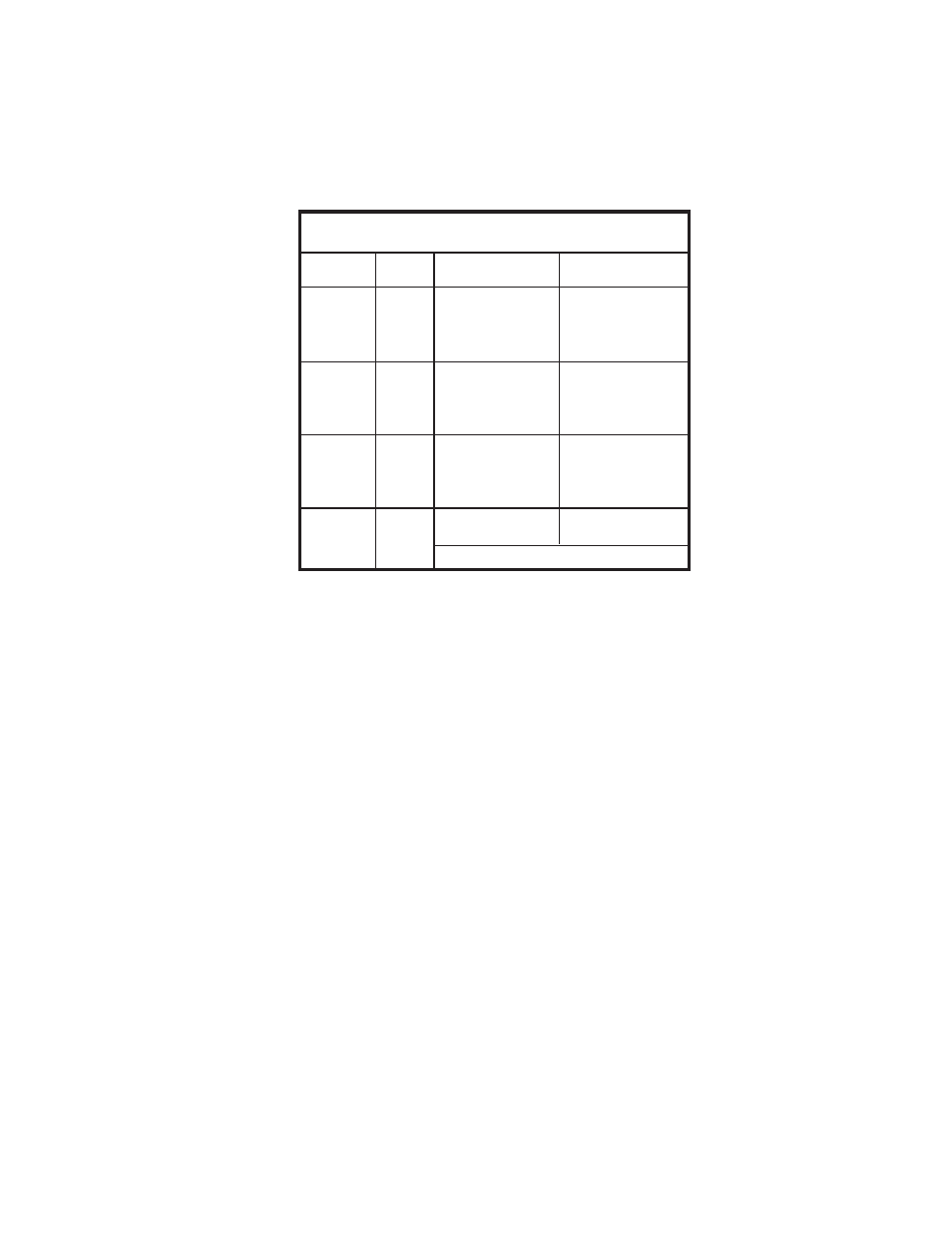

a drop in line voltage, resulting in loss of power and overheating. Fig. D, shows the correct gauge to use depending

on the cord length. If in doubt, use the next heavier gauge. The smaller the gauge number, the heavier the cord.

EXTENSION CORDS

OPERATING INSTRUCTIONS

FOREWORD

The Limited Edition 10" Unisaw is available with either the 52" Unifence Saw guide, or the 50" Commercial Biesemeyer

Fence system. The Limited Edition 10" Unisaw is a very powerful machine. The motor is single phase, 3 horse power,

230 volt motor that turns the circular blade at 4000 RPMs. The Unisaw is a versatile machine, in that it can do precision

ripping, cross-cutting, dadoing, moulding and tenoning.

UNPACKING AND CLEANING

Carefully unpack the machine and all loose items from the shipping container(s). Remove the protective coating from

all unpainted surfaces. This coating may be removed with a soft cloth moistened with kerosene (do not use acetone,

gasoline or lacquer thinner for this purpose). After cleaning, cover the unpainted surfaces with a good quality household

floor paste wax. Figures 1 and 2, illustrate the saw and all loose items supplied with the machine. Figs. 3, 4, and 5,

illustrate the items supplied with the fence system.

IMPORTANT: The saw is shipped with the saw arbor in the 45 degree position. NOTE: THE HAND WHEEL MUST BE

ASSEMBLED TO THE SAW, SEE THE SECTION “ASSEMBLING BLADE TILTING MECHANISM”, THEN PROCEED

WITH THE FOLLOWING. Loosen locking knob on the handwheel (A) Fig. 1, and turn handwheel until the saw arbor is

in the 90 degree position and remove the styrofoam packing from inside the saw cabinet. Tighten locking knob.

NOTICE: THE MANUAL COVER PHOTO ILLUSTRATES THE CURRENT

PRODUCTION MODEL. ALL OTHER ILLUSTRATIONS ARE REPRESENTATIVE

ONLY AND MAY NOT DEPICT THE ACTUAL COLOR, LABELING OR

ACCESSORIES.

5

Fig. D

MINIMUM GAUGE EXTENSION CORD

RECOMMENDED SIZES FOR USE WITH STATIONARY ELECTRIC MACHINES

Ampere

Total Length

Gauge of

Rating

Volts

of Cord in Feet

Extension Cord

0-6

240

up to 50

18 AWG

0-6

240

50-100

16 AWG

0-6

240

100-200

16 AWG

0-6

240

200-300

14 AWG

6-10

240

up to 50

18 AWG

6-10

240

50-100

16 AWG

6-10

240

100-200

14 AWG

6-10

240

200-300

12 AWG

10-12

240

up to 50

16 AWG

10-12

240

50-100

16 AWG

10-12

240

100-200

14 AWG

10-12

240

200-300

12 AWG

12-16

240

up to 50

14 AWG

12-16

240

50-100

12 AWG

12-16

240

GREATER THAN 100 FEET NOT RECOMMENDED