Machine use – Delta 18-900L User Manual

Page 19

19

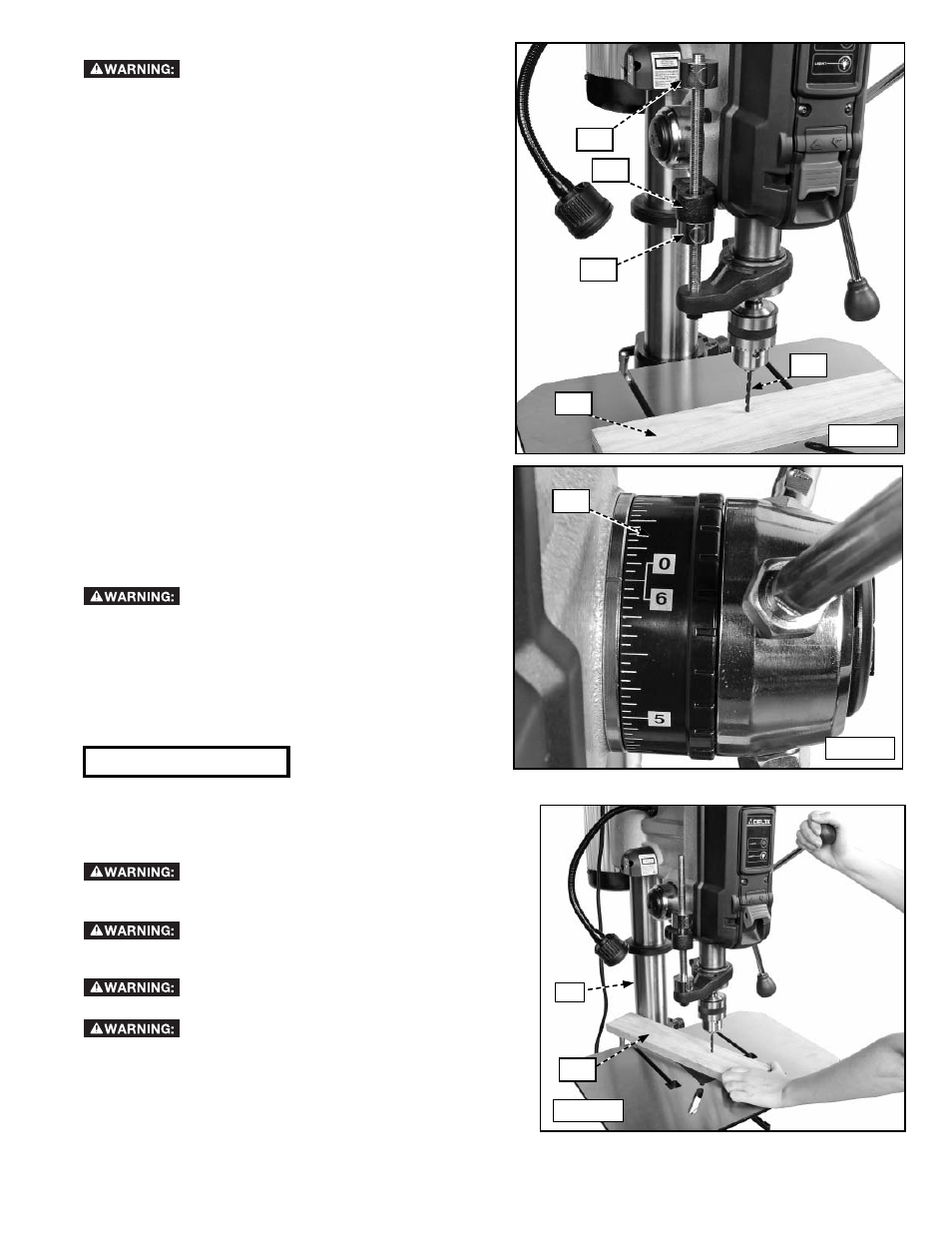

NOTE: Use drill bits with shank diameters of 5/8" or

less.

NOTE: After installing a drill bit, use the supplied key to

tighten all three locations on the chuck.

To reduce the risk of injury, tighten all

lock handles before starting the machine. Loss of

control of the workpiece can cause serious injury.

To reduce the risk of injury, properly

support long or wide work-pieces. Loss of control of

the workpiece can cause severe injury.

To reduce the risk of injury, do not place

more than 250 pounds (113 kg) of weight on the table.

The use of accessories and attachments

not recommended by Delta may result in risk of

injury.

IMPORTANT: When the workpiece (M1) Fig. 45 is

long enough, position it on the table with one end

against the left side of the column (R1) to prevent the

workpiece from rotating. If it is not possible to support

the workpiece against the column, clamp the workpiece

to the table.

MACHINE USE

DRILLING HOLES TO DEPTH

To reduce the risk of injury, turn unit off

and disconnect it from power source before installing

and removing accessories, before adjusting or when

making repairs. An accidental start-up can cause injury.

When you want to drill a number of holes to the same

depth, follow this procedure:

Setting zero

1. Place bit (L1) in chuck Fig. 43.

2. Lower the bit until it touches workpiece (M1)

Fig. 43.

3. Raise the quill locking nut (N1) by pressing button

and raising it up against the depth stop bracket

(O1).

4. Turn scale on the pinion (P1) Fig. 44 to the zero

mark.

Set depth

1. Remove the workpiece and rotate pinion handles to

lower quill to desired drilling depth as registered on

the scale.

2. Holding the quill at this depth, raise the quill locking

nut (N1) Fig. 43 back up against the depth stop

bracket.

3. Still holding the spindle, lower the depth stop nut

(Q1) Fig. 43 down against depth stop bracket.

4. Lower the quill locking nut (N1) Fig. 43 out of the

way.

To reduce the risk of injury, tighten all lock

handles before starting the machine. Loss of control of

the workpiece can cause serious injury.

5. Connect the machine to the power source and drill

a test hole to check the adjustment. Readjust, if

necessary, by rotating the stop nut (Q1) Fig. 43 for

fine adjustment. You do not have to depress the

button to rotate the stop nut (Q1).

L1

Fig. 43

Fig. 44

M1

M1

R1

Q1

O1

N1

P1

Fig. 45