Delta 18-900L User Manual

Page 11

11

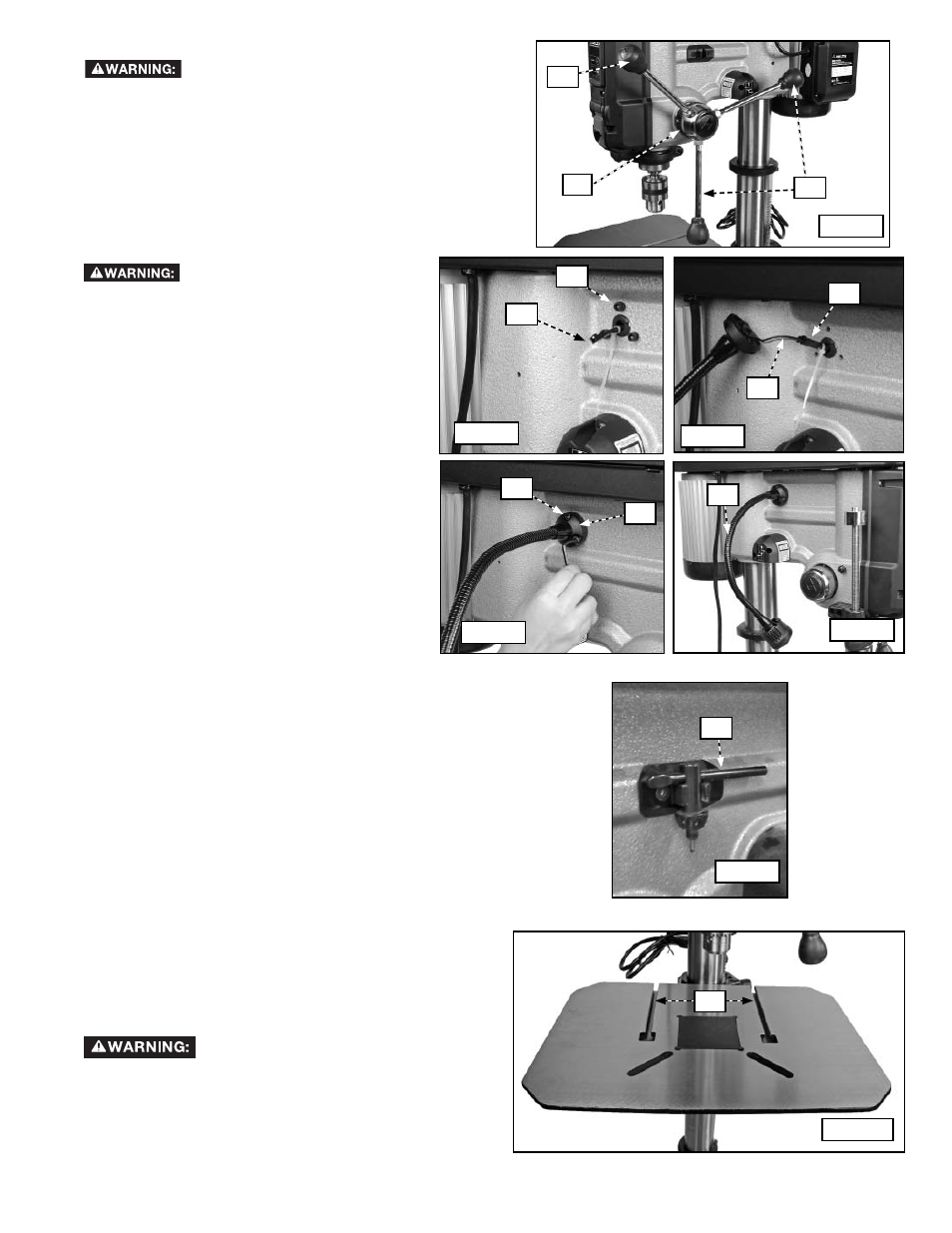

ATTACHING THE PINION SHAFT HANDLES

To reduce the risk of injury, turn unit off

and disconnect it from power source before installing

and removing accessories, before adjusting or when

making repairs. An accidental start-up can cause injury.

Thread the three pinion shaft handles (AA) in the three

holes located in the pinion shaft hub (BB) Fig. 14.

ATTACHING THE

LED WORK LIGHT

To reduce the risk of injury, turn

unit off and disconnect it from power source

before installing and removing accessories,

before adjusting or when making repairs. An

accidental start-up can cause injury.

The included LED work light is to be attached to

the side of the headstock at wire (CC) Fig. 15.

NOTE: Prior to connection, be careful not to

push wire (CC) into headstock as it is difficult to

retrieve.

1. Remove three 6 mm screws (one shown at

DD) Fig. 15.

2. Connect the two wires — (CC) from the

headstock and (EE) from the LED worklight

— as shown in Fig. 16.

3. Remove plastic cable tie.

4. Push excess wire into the headstock.

5. Attach the LED work light (FF) Fig. 17 to

the headstock using three screws removed

earlier. One is shown at (DD).

6. Final assembly of LED worklight (FF) looks

like Figure 18.

CHUCK KEY STORAGE

Storage for your included chuck key (GG) is built into the

right side of the drill press head stock. Press chuck key

into the holder as shown in Figure 19.

Fig. 19

T-SLOTS

The drill press table is fitted with two T-slots (HH) Fig. 20

for use with various drill press accessories (stop blocks,

fences, or clamps). Use 5/16" T-bolts or 1/4-20 hex head

bolts when attaching your accessory to the table.

Since accessories other than those

offered by DELTA have not been tested with this

product, use of such accessories could be hazardous.

For safest operation, only DELTA recommended

accessories should be used with this product.

HH

Fig. 20

FF

DD

AA

AA

Fig. 14

Fig. 15

CC

CC

Fig. 16

Fig. 17

EE

Fig. 18

FF

GG

BB

DD