Machine use – Delta SS350LS User Manual

Page 14

14

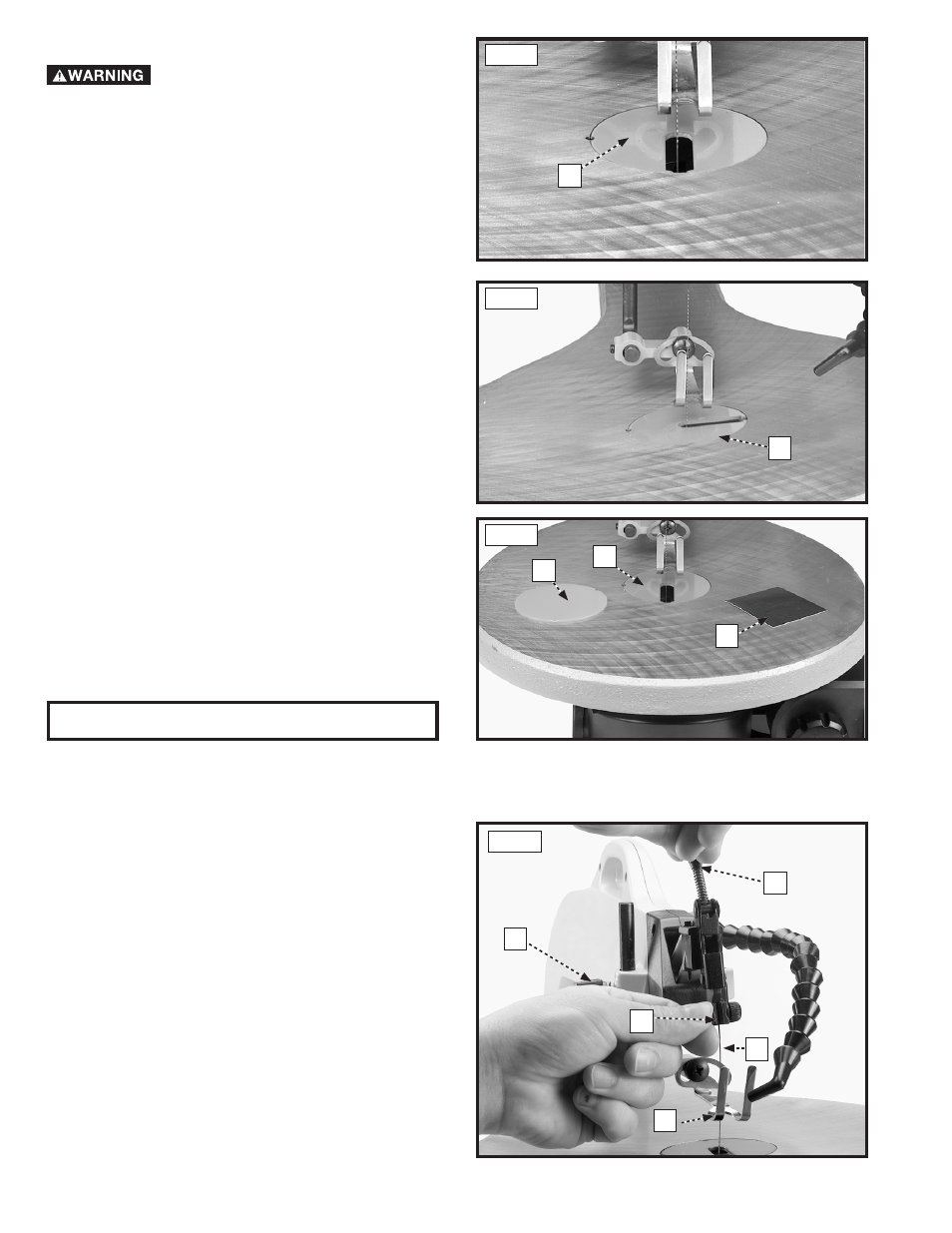

TABLE INSERT

Disconnect machine from power source.

The table insert (A) can be positioned in the saw table with

the opening in the insert pointing to the front of the table, as

shown in Fig. 18, or to the right as shown in Fig. 19.

With the table in the level position, 90° to the blade, the insert

(A) should be positioned, as shown in Fig. 18. This allows for

the blade to be pivoted forward after it is unclamped from the

top blade holder, enabling you to quickly insert the blade into

the next hole in a pattern when doing inside-cutting, as you

will see later in this manual.

When tilting the table for bevel cutting operations the insert

(A) should be positioned as shown in Fig. 19. This allows for

clearance of the blade when tilting the table.

A blank table insert (B) Fig. 20, is supplied as standard

equipment with your scroll saw and can be used when

cutting very small workpieces to give added support to

the bottom of the workpiece. Cut a slot into the blank and

replace the standard insert (A) with the blank (B). The slot

cut into the blank (B) will only be as wide as the blade giving

maximum support to the bottom of the workpiece. Adhesive

backed spacer pads (C) are also supplied for adjusting the

table insert height relative to the table surface. Place three

pads an equal distance apart on a cleaned surface to be

applied to the blank insert. Pads can be stacked in order to

achieve desired insert height.

MACHINE USE

FOLLOWINg A LINE

With your scroll saw you should be able to perform straight or curved cuts with ease. Most beginners will experience

blade wandering; however, they eventually learn to control it as they become more familiar with the machine. Use

scrap material to practice cuts before starting a project. This

enables you to develop your own style of cutting and you will

discover what you can do with your saw.

Always hold the work firmly against the table and do not feed

the workpiece too fast while cutting. Feed the workpiece only

fast enough so that the blade will cut. Scroll saws cut faster

across the grain than they do with the grain. Allow for this

tendency when cutting patterns that shift rather quickly from

with-the-grain cuts to cross-grain cuts.

Make "relief" cuts before cutting long curves and never

attempt to cut a curve that is too tight for the blade being

used.

Fig. 18

A

A

Fig. 19

A

B

C

Fig. 20

Fig. 21

A

B

C

D

E