English checking belt tension (fig. 1), Adjusting belt tension, Pulley and fly wheel alignment – DeWalt D55273 User Manual

Page 17

17

English

Checking Belt Tension (Fig. 1)

WARNING: Hot surfaces. Risk of burn. Aftercooler, pump head,

and surrounding parts are very hot, do not touch (see the Hot

Surfaces identified in Fig. 2). Allow compressor to cool prior to

servicing.

1. Ensure engine ON/OFF switch (C) is in the OFF Position.

2. Allow the unit to cool.

3. Disconnect spark plug wire.

4. Drain air tank.

5. Remove eight belt guard screws.

6. Remove outer belt cover.

7. Measure belt tension. Proper tension is achieved when a three

(3) pound weight or equivalent finger pressure applied midway

between the motor pulley and compressor flywheel causes a

1/4" (6.35 mm) deflection of the belt., if adjustment is needed

see Adjusting Belt Tension under Maintenance.

8. Replace belt guard.

9. Reconnect spark plug wire.

Adjusting Belt Tension

WARNING: Hot surfaces. Risk of burn. Aftercooler, pump head,

and surrounding parts are very hot, do not touch (see the Hot

Surfaces identified in Fig. 2). Allow compressor to cool prior to

servicing.

1. Ensure engine ON/OFF switch (C) is in the OFF position.

2. Allow the unit to cool.

3. Disconnect spark plug wire.

4. Drain air tank

5. Loosen but do not remove four pump mounting bolts.

6. Remove eight belt cover screws.

7. Remove outer belt cover.

8. Loosen but do not remove pump stiffener

T

bracket bolt (T).

9.

Turn belt tensioning (S) bolt

clockwise to increase belt tension or

counterclockwise to loosen belt tension.

10. Check the belt tension again. See Step

7 in Checking Belt Tension under

Maintenance.

11. When tension is correct, retighten four

S

pump mounting bolts (torque to

18– 22 ft.- lbs./24.4–29.8 Nm), stiffener

bracket bolt (torque to 18–

22 ft.-

lbs./

24.4– 29.8 Nm), and replace belt cover.

12. Reconnect spark plug wire.

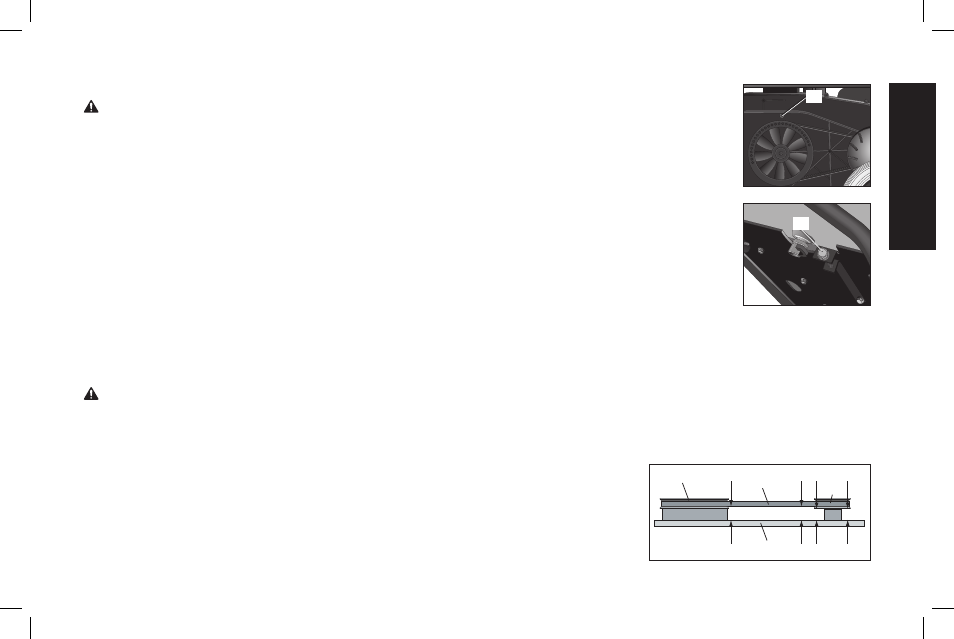

Pulley and Fly wheel

Alignment

The air compressor flywheel and engine pulley must be in-line (in

the same plane) within 1/16" (1.6 mm) to ensure belt retention within

flywheel belt grooves. To check alignment:

1. Ensure engine ON/OFF switch (C) is in the OFF Position.

2. Allow the unit to cool.

3. Disconnect spark plug wire.

4. Drain air tank.

5. Remove outer belt cover.

6.

Place a straightedge

X

U

W

A1

A1

A2

A2 B1

B2

B1

B2

V

(U) against the outside

of the flywheel (W) and

the engine drive pulley

(X).