Vortech 1998-2001 5.7L LS1 F-Body User Manual

Page 16

P/N: 4GK020-010

©2003 Vortech Engineering, LLC

All Rights Reserved, Intl. Copr. Secured

09JUN03 v3.2

(FBodyLS1(4GK V3.2)98-02)

4

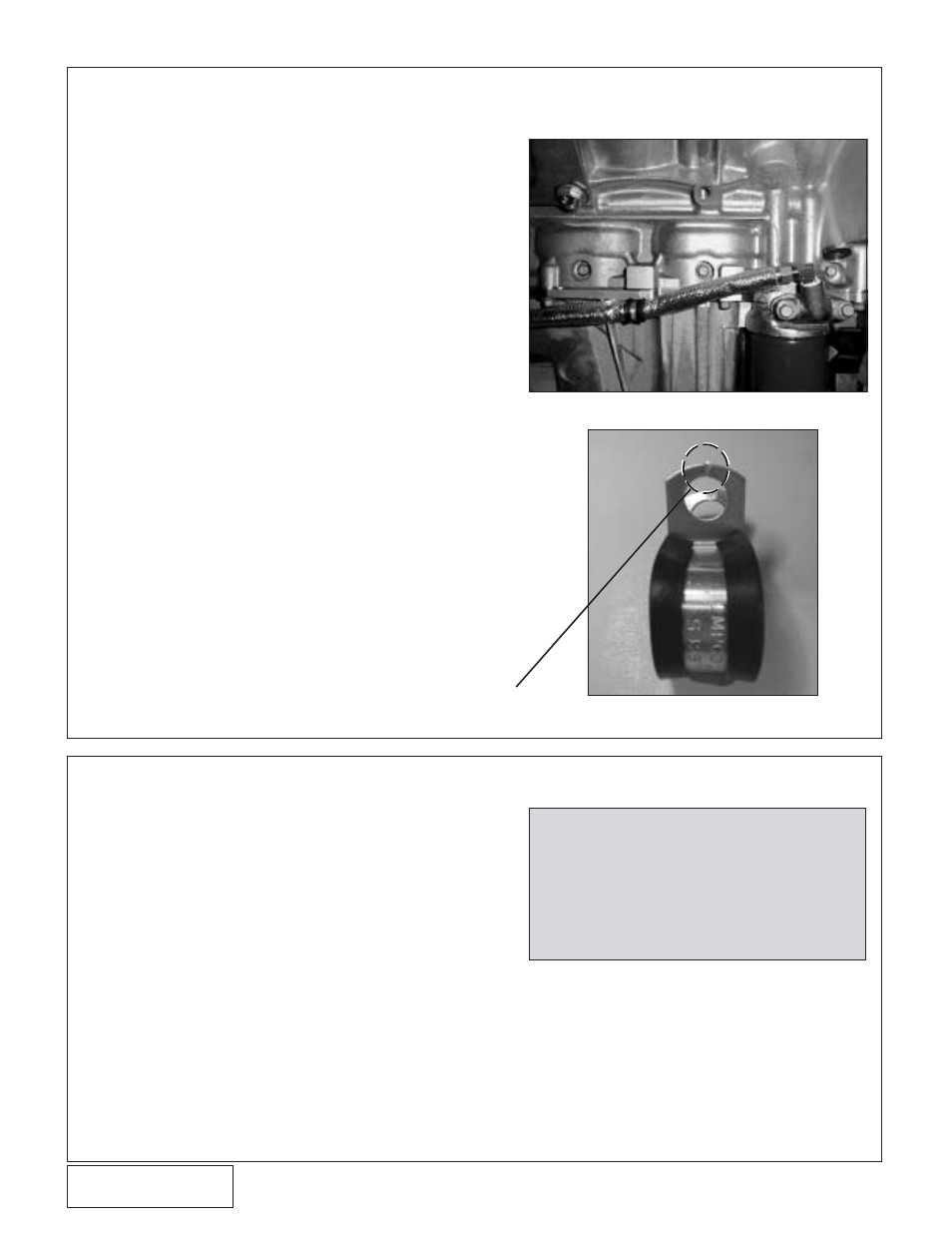

4. OIL FEED LINE

A. Spray the nuts securing the driver’s side catalytic

converter with penetrating oil and remove. Use

caution not to shear off the exhaust manifold

studs!

B. Remove the two bolts holding the small casting

located just above the oil filter.

C. Drill through the existing hole in the casting neck

with an “R” drill bit and tap 1/8” NPT. Thoroughly

clean the neck with solvent to remove metal clips.

D. Using engine oil on the threads, install the

supplied 1/8” NPT to #4 90

°

fitting so it will point

forward and away from the exhaust when

installed on the vehicle (see

Figure 4-a).

E. Reinstall the neck into its original position.

F. Temporarily cover one end of the oil feed line and

protect it from debris until connecting it to the

supercharger.

G. Connect the open end of the oil feed line to the

fitting. Install the fire sleeve on the portion of the

oil feed line that is near the exhaust and secure

both with an adel clamp. Route the line along the

oil pan rail to the front of the engine. Use an adel

clamp at the front of pan and tie wraps to secure

the line and protect it from kinking, abrasion, and

high heat areas. From the front of the pan, leave

the oil feed line loose (routing will be completed

after the supercharger is installed). The adel

clamps will need to be clipped with side cutters

to allow the bolt to pass through the hole (see

Fig. 4-b).

H. Re-install the catalytic converter.

5.

HARMONIC DAMPER INSTALLATION

A. Make sure no debris or oil is on the crank snout

or inner bore of the supplied damper.

B. Use the damper installation tool to seat the

damper on the crankshaft. (See Tool & Supply

Requirements on page v.)

C. Install per factory manual as follows:

1. Install the original retaining bolt and torque to

240 ft/lb. Remove the bolt.

2. Lightly coat the threads of the new retaining

bolt with red threadlocker. Install and torque

to 37 ft/lbs.

3. Using 1/2" breaker bar, tighten the retaining

bolt an additional 120

°

or tighten with a torque

wrench to 250 ft/lbs.

D. Use a small amount of paint or equivalent to mark

the retaining bolt and balancer hub so that any

relative movement between the two will be easy

to check after the vehicle has been operated.

Fig. 4-a

Fig. 4-b

NOTE:

It is helpful to mark the breaker bar

location on the damper under light

torque. Tighten the bolt until the

breaker bar is at the same position

under the same light torque as used

previously, but is advanced two flats

on the bolt head. This yields 120

°

of

bolt rotation.

CLIP HERE