Vortech 1996-2000 5.7L Vortec Truck/SUV User Manual

Page 11

P/N: 4GM020-010

©2000 Vortech Engineering, Inc.

All Rights Reserved, Intl. Copr. Secured

14AUG00 V 1.2

(Vortec 350-2 )4GM

4.

MAIN BRACKET

A. To accommodate the relocation of the alternator

onto the new main bracket, the brown field wire

must be extended approximately 12”. Proceed by

cutting the wire approximately 4” from the factory

plug that attaches to the alternator. Splice the

supplied piece of brown wire into the cut wire by

soldering. Use the supplied piece of heat shrink

tubing to seal the joints. Re-wrap the wire/harness

with the supplied length of plastic flex-loom.

B. The transmission cooler lines must be bent down-

ward as far as possible (toward the frame) to

obtain alternator clearance. Rotate the lower ra-

diator hose clamp (at the water pump) 90

°

toward

the front (the clamp tabs should be facing the front

of the vehicle).

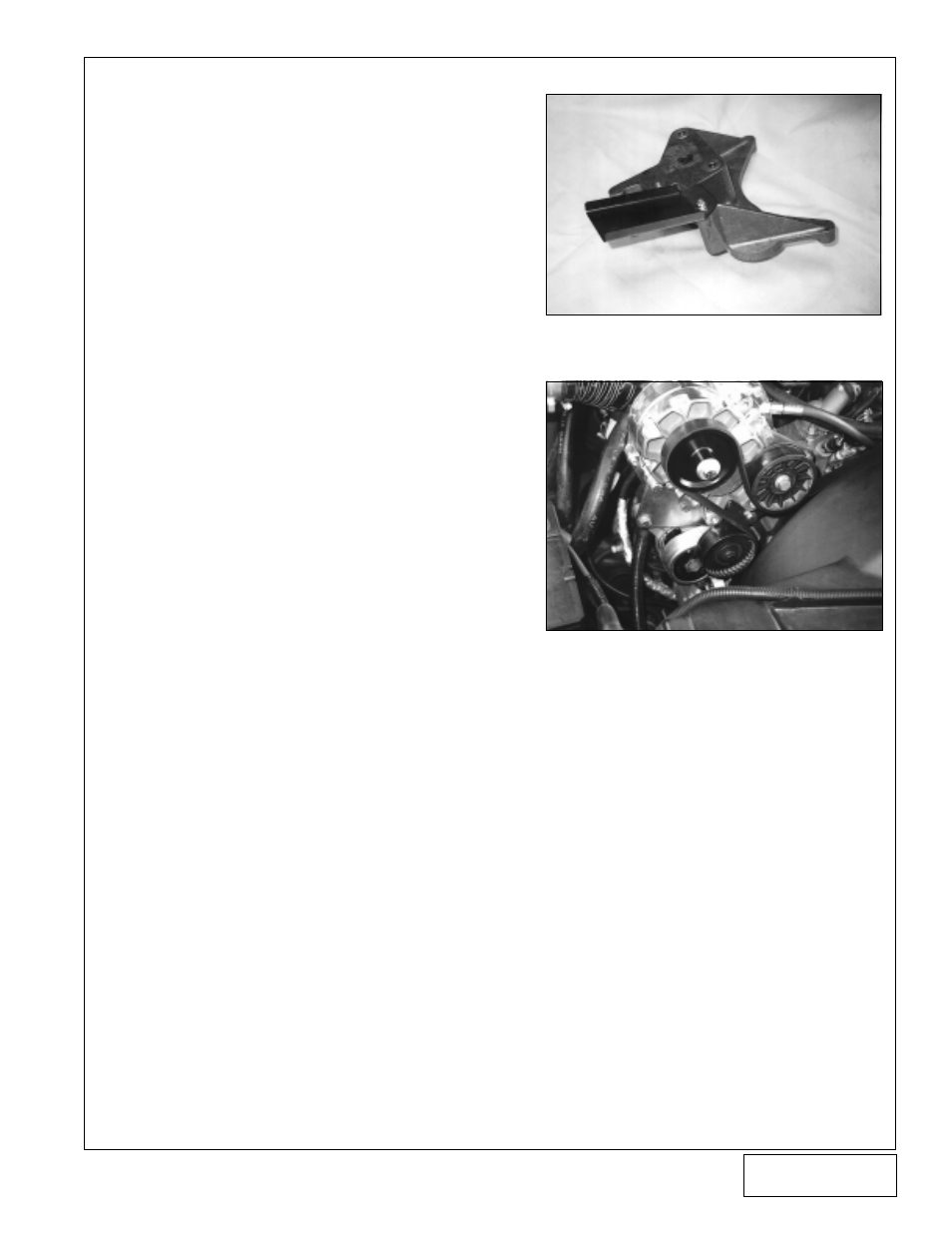

C. Attach the supplied stainless steel heat shield onto

the rear of the Vortech main bracket using the

supplied 1/4” hardware (see

Fig. 4-a

).

D. Place the mounting bracket on the front of the

passenger side cylinder head. Line up the bracket

with the holes on the front of the head and block

and start the 3/8-16 socket head bolt into the

lowest bracket hole. Install the two 3/8-16 x 1.25”

bolts and washers into the two remaining upper

holes. Torque the three bolts evenly.

E.

Reattach the field wire and positive wire to the

alternator (make sure that the large positive wire

has the factory rubber boot properly secured to

prevent arcing to the heat shield). Using the sup-

plied 3/8-16 x 2.75” bolts and washers, attach the

alternator to the main bracket. Secure all alternator

wiring from heat and sharp objects.

F.

Align the supercharger mounting plate with the

bracket and secure with the supplied 3/8-16 x 3/4”

bolts and AN washers.

G. Mount the supplied automatic belt tensioner onto

the main bracket. (See

Fig. 4-b

.) Rotate the unit so

that the small alignment pins fall into the corre-

sponding holes in the bracket. Secure the tensioner

using the supplied M10 bolt.

3

Fig. 4-a - Stainless Steel Heat Shield.

Fig. 4-b