Wiring, Grounding the module, System wiring guidelines – Spectrum Controls 1762sc-OF8 User Manual

Page 9

MicroLogix™ Analog Output Module

16

Publication 0100163-01 Rev. B

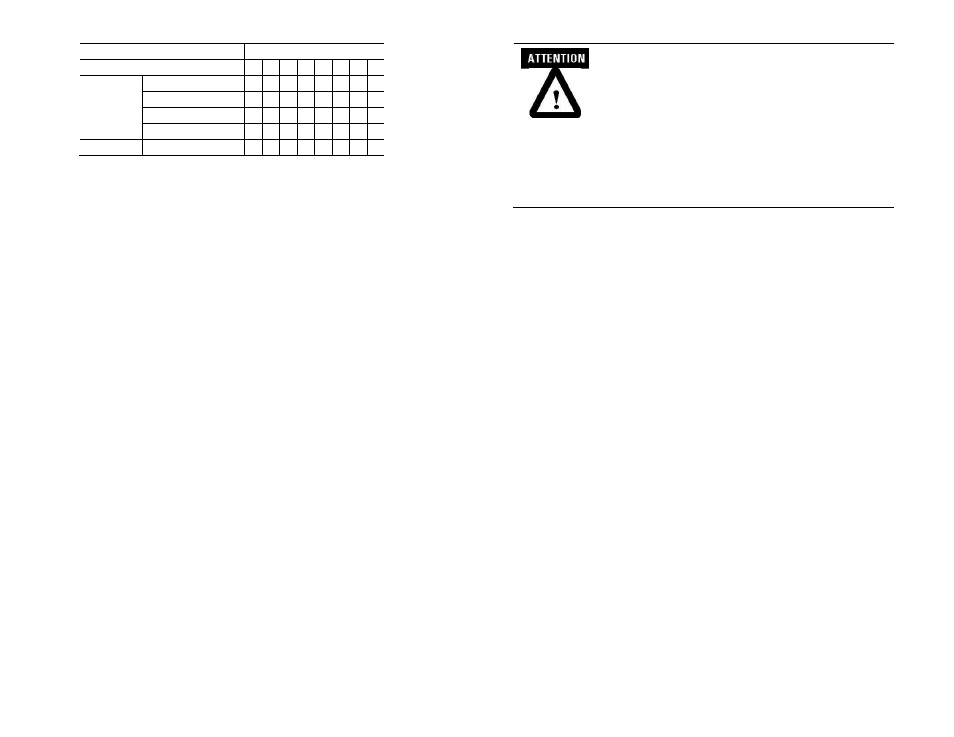

To Select

Make these bit settings

7 6 5 4

3

2

1

0

Data Format

Scaled for PID

0

0

Engineering Units

0

1

Percent Range

1

0

Raw/Proportional Data

1

1

Unused

0 0 0

MicroLogix™ Analog Output Module

9

Publication 0100163-01 Rev. B

EXPLOSION HAZARD

• In Class I, Division 2 applications, the bus connector must

be fully seated and the bus connector cover must be snapped

in place.

• In Class I, Division 2 applications, all modules must be

mounted in direct contact with each other as shown on page

6. If DIN rail mounting is used, an end stop must be

installed ahead of the controller and after the last 1762 I/O

module.

Wiring

Grounding the Module

Grounding for this product is provided by the MicroLogix™ 1100, 1200 or 1400

CPU via the bus ribbon cable. Refer to Industrial Automation Wiring and Grounding

Guidelines, Allen-Bradley publication 1770-4.1, for additional information.

System Wiring Guidelines

Consider the following when wiring your system:

The analog common (COM) is not connected to earth ground inside the

module. All terminals are electrically isolated from the system.

Use Belden™ 8761, or equivalent, shielded wire.

Under normal conditions, the drain wire (shield) should be connected to

the metal mounting panel (earth ground) as close to the module as

possible. Keep the shield connection to earth ground as short as possible.

To ensure optimum accuracy for voltage type outputs, limit overall cable

impedance by keeping all analog cables as short as possible. Locate the

I/O system as close to your voltage type sensors or actuators as possible.

Digital and analog power must be supplied by an Isolated Secondary

Limited Energy Low Voltage source.

Use supply wires for 20˚ C above surrounding ambient.