Wire size and terminal screw torque, Addressing, Input data file – Spectrum Controls 1762sc-OF8 User Manual

Page 12: Configuration data file, Output data file

MicroLogix™ Analog Output Module

12

Publication 0100163-01 Rev. B

Wire Size and Terminal Screw Torque

Each terminal accepts up to two wires with the following restrictions:

Wire Type

Wire Size

Terminal Screw

Torque

Solid

Cu-90°C (194°F)

#14 to #22 AWG

0.904 Nm (8 in-lbs)

Stranded Cu-90°C (194°F)

#16 to #22 AWG

0.904 Nm (8 in-lbs)

I/O Memory Mapping

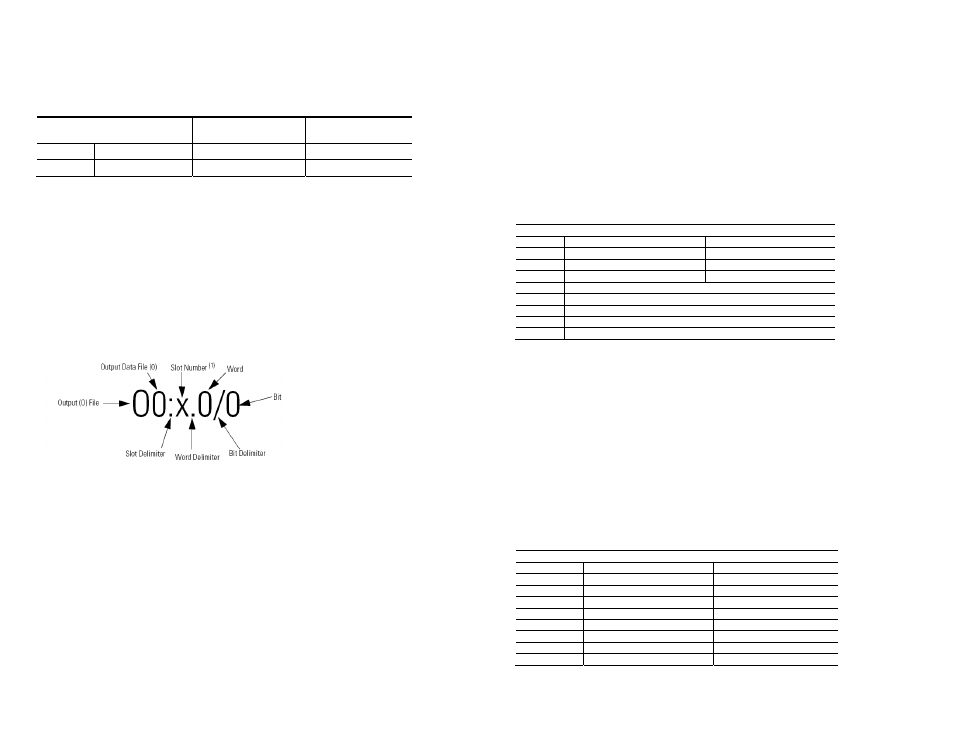

Addressing

The addressing scheme for 1762 Expansion I/O is shown below.

(1)

I/O located on the controller (embedded I/O) is slot 0. I/O added to the controller (expansion I/O) begins

with slot 1.

MicroLogix™ Analog Output Module

13

Publication 0100163-01 Rev. B

Input Data File

For each module, slot x, input words 0 through 7 contain module status

information including channel status and configuration status. During module

configuration, the module enters a special mode called Command Mode. During

Command Mode, configuration data is written to the module using the output data

file and Command Mode response data is returned to words 0 through 2 in the

input data file. After the Command Mode process completes, the module returns

to normal run mode. The table below shows the layout for each word during both

modes of operation.

Input Data File

Input File(Read Only)

Normal Run Mode

Command Mode

I:e.0

General Status Word 0

Command Echo

I:e.1

Output Status Word 1 (ch 0-3)

Response Code

I:e.2

Output Status Word 2 (ch 4-7)

Response Channel

I:e.3

Echo Config (ch 0-1)

I:e.4

Echo Config (ch 2-3)

I:e.5

Echo Config (ch 4-5)

I:e.6

Echo Config (ch 6-7)

I:e.7 Not

Used

Configuration Data File

The configuration data file is not used. Instead the output data file is used to

configure the module and control output channels 0 through 7.

Output Data File

This section describes how the input and output files are used together to configure

the module. The module enters a special mode called Command Mode when the

PLC transitions from Program mode to Run mode. After the module enters

Command Mode, the output file is used to send commands to the module and the

module responds via the input data file. The table below shows the layout for each

word during both modes of operation.

Output Data File

Output File

Normal Run Mode

Command Mode

O:e.0

Channel 0 Data Word

Command

O:e.1

Channel 1 Data Word

Data Word 1 (Ch0 & 1)

O:e.2

Channel 2 Data Word

Data Word 2 (Ch2 & 3)

O:e.3

Channel 3 Data Word

Data Word 3 (Ch4 & 5)

O:e.4

Channel 4 Data Word

Data Word 4 (Ch6 & 7)

O:e.5

Channel 5 Data Word

Fixed Word 1 (0xCDEF)

O:e.6

Channel 6 Data Word

Fixed Word 2 (0xFEDC)

O:e.7

Channel 7 Data Word

Fixed Word 3 (0x5A5A)