Warning – Sioux Tools SSD10S User Manual

Page 3

Form ZCE798

3

Date 2013February1/D

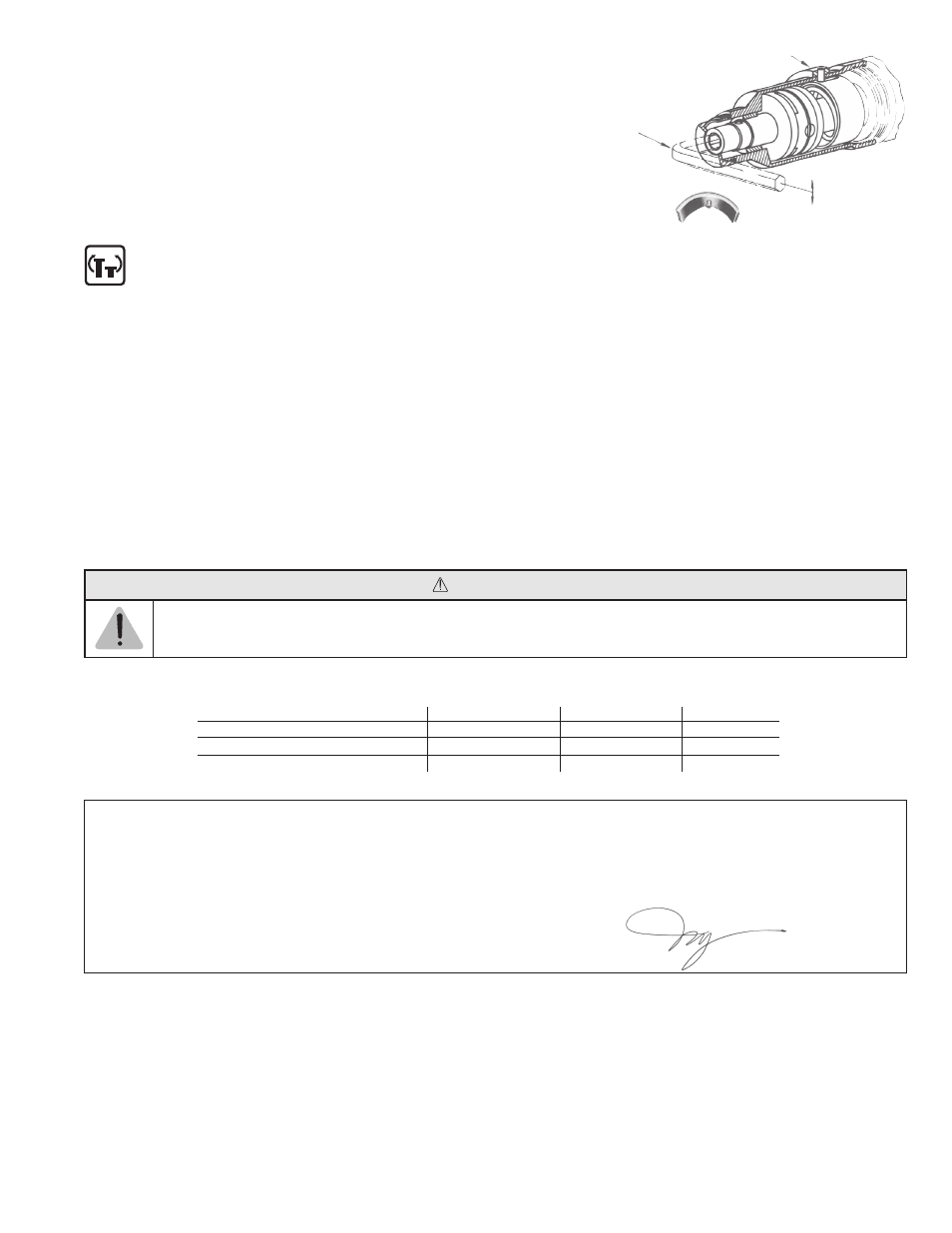

ADJUSTMENT OF ADJUSTABLE CLUTCH

ABOVE 25 INCH POUNDS

To adjust clutch place adjusting wrench (No. 53099) with pin through opening in the clutch

case. Place 1/4” (6.4 mm) HEX wrench in the Bit Holder, press in and turn until adjusting

wrench falls into the slot of the Nut of the Clutch. Keep Bit Holder depressed in with HEX

Wrench and turn clockwise to increase and counterclockwise to decrease Torque.

BELOW 25 INCH POUNDS CHANGE TO GREEN SPRING NO. 41284

Again place adjusting wrench in position as for the higher Torque, but place a screw driver

blade through the bit holder opening until in contact with the slot at the far end. Rotate screw

driver until adjusting wrench falls into place, again rotate screw driver clockwise to increase

and counterclockwise to decrease Torque.

REVERSE OPERATION

On reversing tools, the direction of spindle rotation is controlled by the reversing button. When the button is depressed, the spindle rotates

counterclockwise. Always depress the button fully to obtain full power. The reversing button on some models can be locked in the reverse

direction by fully depressing and rotating the button clockwise.

AIR SUPPLY

The efficiency and life of this tool depend on the proper supply of clean, dry air at a maximum of 90 PSI. The use of an air line filter, pressure regulator,

and lubricator is recommended.

Before connecting to tools, blow out the air line to remove water and dirt that may have accumulated.

HOSE AND HOSE CONNECTIONS

The air supply hose recommended is 3/8” (10mm) I.D. If an extension hose is necessary, use 1/2” (13mm) ID hose with couplings not less than 3/8”

(10mm) I.D.

LUBRICATION

For maximum performance and tool life, an air line lubricator, set to deliver 2 drops per minute, is recommended. SIOUX No. 288 Air Motor Oil is rec-

ommended.

If an airline lubrication is not used, it is recommended that the tool be oiled daily before use to improve performance. Add 2-4 drops of air motor oil and

run the tool for 10-20 seconds to distribute oil through the tool.

Lubricate the gears through the grease fitting with Sioux 1232A grease after 100 hours of operation.

MAINTENANCE

Water, dust and other airline contaminants can cause rust and vane sticking. For long periods between tool use, flush the tool with a few drops of oil

and run for 10 seconds. This will help remove contaminants and reduce the formation of rust.

Catalog No.

*Sound Pressure dBA *Sound Power dBA *Vibration m/s

2

SSD10S - Adjustable Clutch

80.0

91.6

3.8

SSD10S - Stall Drive

80.0

91.6

Less than 2.5

*per PN8NTC1

*per PN8NTC1

*per ISO 8662

SOUND AND VIBRATION READINGS

DECLARATION OF CONFORMITY

We, Sioux Tools Inc., 250 Snap-on Drive, P.O. Box 1596, Murphy, NC, 28906, USA, declare under our sole responsibility that the products

SSD10S SERIES

to which this declaration relates are in conformity with the following standard or standards or other normative document or documents:

EN 792, EN 292 Parts 1&2, ISO 8662, Pneurop PN8NTC1

following the provisions of

98/37/BC.

Signature of issuer

December 1, 2008

Murphy, North Carolina, USA

Date and place of issues

Mark S. Pezzoni

President

Power and Specialty Tools

Name and position of issuer

ADJUSTING WRENCH

DEPRESS SPINDLE TO

ENGAGE CLUTCH JAWS

DECREASE

INCREASE

53099

WARNING

Disconnect tool from air supply before performing any adjustment, maintenance, or repair.