Remy 50DN OIL-COOLED GENERAT0RS User Manual

Page 2

Technical support: USA 800 854 0076, Mexico 01 800 000 7378, Brazil 0800 703 3526, South America 55 11 2106 6510 or visit

delcoremy.com

NOTICE

- Only licensed Remy International, Inc. product and component parts should be used, and the use of other parts or modifications not approved

by Remy International, Inc. will void all applicable warranties. The failure to carefully follow these Installation Instructions, set forth above, will void all

applicable warranties. DELCO REMY is a registered trademark of General Motors Corporation, licensed to Remy International, Inc. Pendleton, IN 46064.

©

2012 Remy International, Inc. All rights reserved

2

DO NOT mix roller bearing races because they are matched for proper roller clearance.

8.

Support inside of rotor with bar stock 2" dia. x 5" long on arbor press. With rotor shaft upright, press on inner race with cylinder used in

Step 7 to press bearing and housing assembly onto shaft.

9.

If alternator uses an 18-tooth gear, install new gear from kit. Torque to 145-155 lb ft (Figure 3). Reassemble generator.

10. Referring to Figure 1, assemble SPECIAL TEE provided in kit into rectifier end frame where elbow was removed. The 1/8-27 pipe

thread fits the thread in the rectifier housing.

SPECIAL TEE MUST BEIt HAS INTERNAL ORIFICE TO REGULATE OIL FLOW. WITHOUT SPECIAL TEE,

STATOR WILL OVERHEAT, CAUSING SHORT LIFE AND ENGINE DAMAGE MAY OCCUR.

11. Assemble oil line between tee in rectifier housing and elbow (from kit) in drive end housing.

12. Locate clamp and drill two .146-.150" diameter holes .40" deep in stator frame and attach using two thread forming screws. NOTICE:

do not drill thru frame, which would result in oil leak.

13. Assemble onto engine and attach oil line (1/2-20 thread). If coach oil line thread is not 11/2-20, add a fitting between tee and oil line.

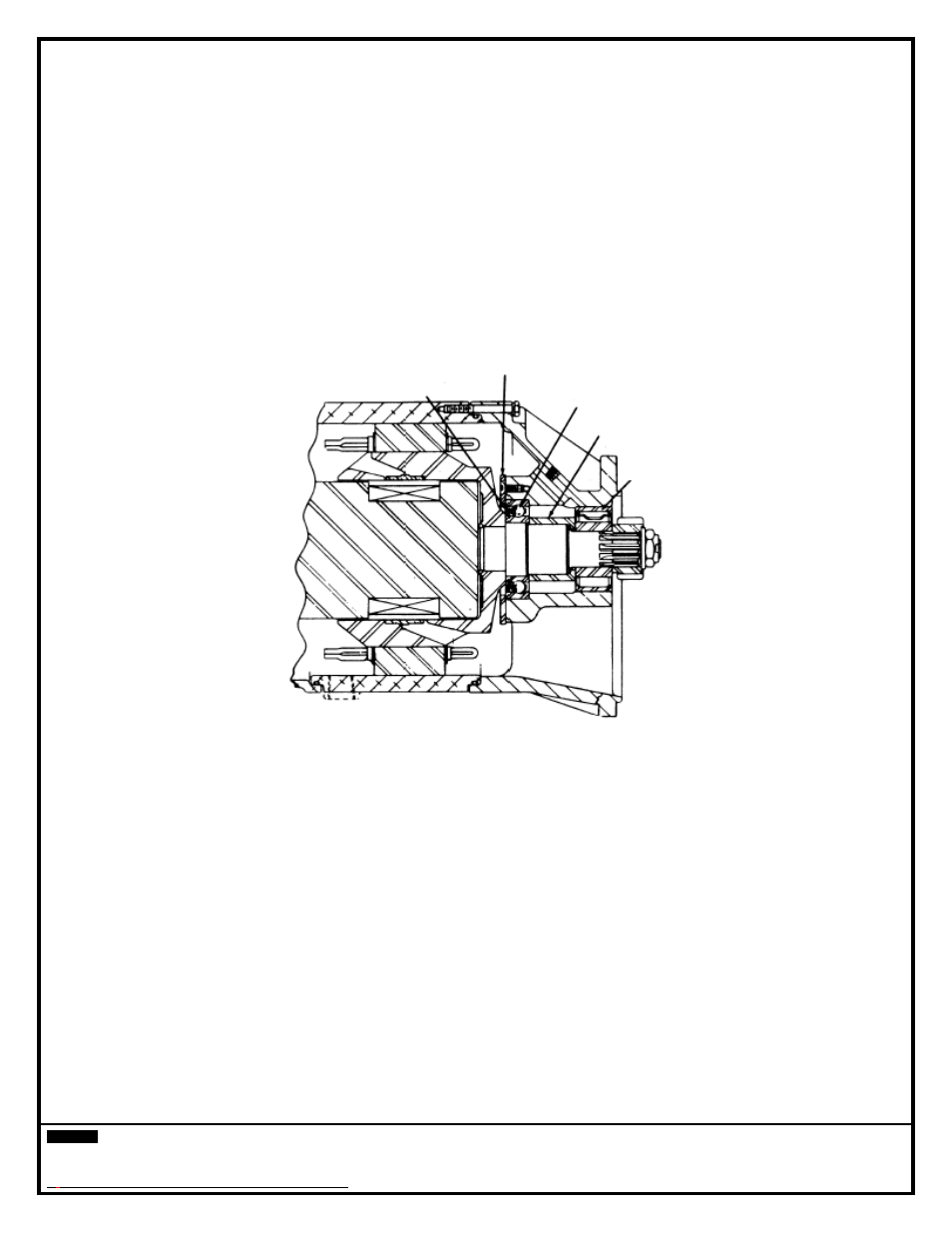

Bearing Seal

Spacer

Retainer Plate

Single Row

Ball Bearing

Roller Bearing

Figure 3