Pressure and temperature limits, Compact mini bench top reactors – Parr Instrument Series 5500 User Manual

Page 7

Compact Mini Bench Top Reactors

w w w . p a r r i n s t . c o m

7

Pressure and Temperature Limits

Working pressures up to 3000 psig (200 bar)

maximum are permissible in these Mini Reactors

when constructed of Type 316 Stainless Steel and

equipped with a magnetic stirrer drive. Pressure

limits for reactors made of materials other than Type

316 Stainless Steel can be obtained from customer

service. No attempt should be made to increase

these limits by making alterations or by substituting

components which are not recommended by Parr

Instrument Company. It must also be understood

that lower pressure and temperature limits may

be required for modified reactors and for vessels

made of special alloys. Limits for such vessels will

be determined by the physical characteristics of the

material of construction and will be prescribed on

an individual basis.

Working temperatures up to 350 ºC are permissible

in Mini Reactors equipped with a standard, flat

gasket, No. 457HC2, made of PTFE fluoropolymer

resin. A PTFE gasket is the recommended choice

for most applications since the PTFE resin is inert

to most chemicals and it will provide good seals

under repeated opening and closing if the gasket

temperature does not exceed 350 ºC. The service

life of a PTFE gasket will, however, be reduced

considerably if used at temperatures above 300 ºC.

For better service in the 300 ºC to 350 ºC operating

range Parr recommends a flexible graphite gasket,

No. 457HC3KL.

The maximum working pressure and temperature

for any vessel is governed by the design of the

vessel and the strength of the material from which

it is constructed. There is also a close relationship

between working pressure and temperature since

the strength of any material will normally fall off as

the temperature is increased.

Temperature and pressure limits are also affected

by the physical properties and temperature limits

of the gaskets and seals used in the vessel, and by

any valves, gages or other fittings attached to the

vessel. Obviously, the safe operating pressure of

any system can be no higher than that of its lowest

rated component.

Working temperatures up to 225 ºC are permissible

in mini reactors equipped with fluoroelastomer

(FKM) O-ring seals. The higher the operating tem-

perature above 200 ºC, the shorter the life of the

O-ring will be. Perfluoroelastomer (FFKM) O-ring

seals have a broad chemical resistance and can be

used to temperatures up to 300 ºC. Unfortunately

they are very expensive and will generally be re-

served for unique applications. Ethylene-propylene

(EP)

O-rings can be used to 170 ºC and are recommend-

ed for applications such as ethers, ammonia and

amines which will rapidly destroy fluoroelastomer

O-rings.

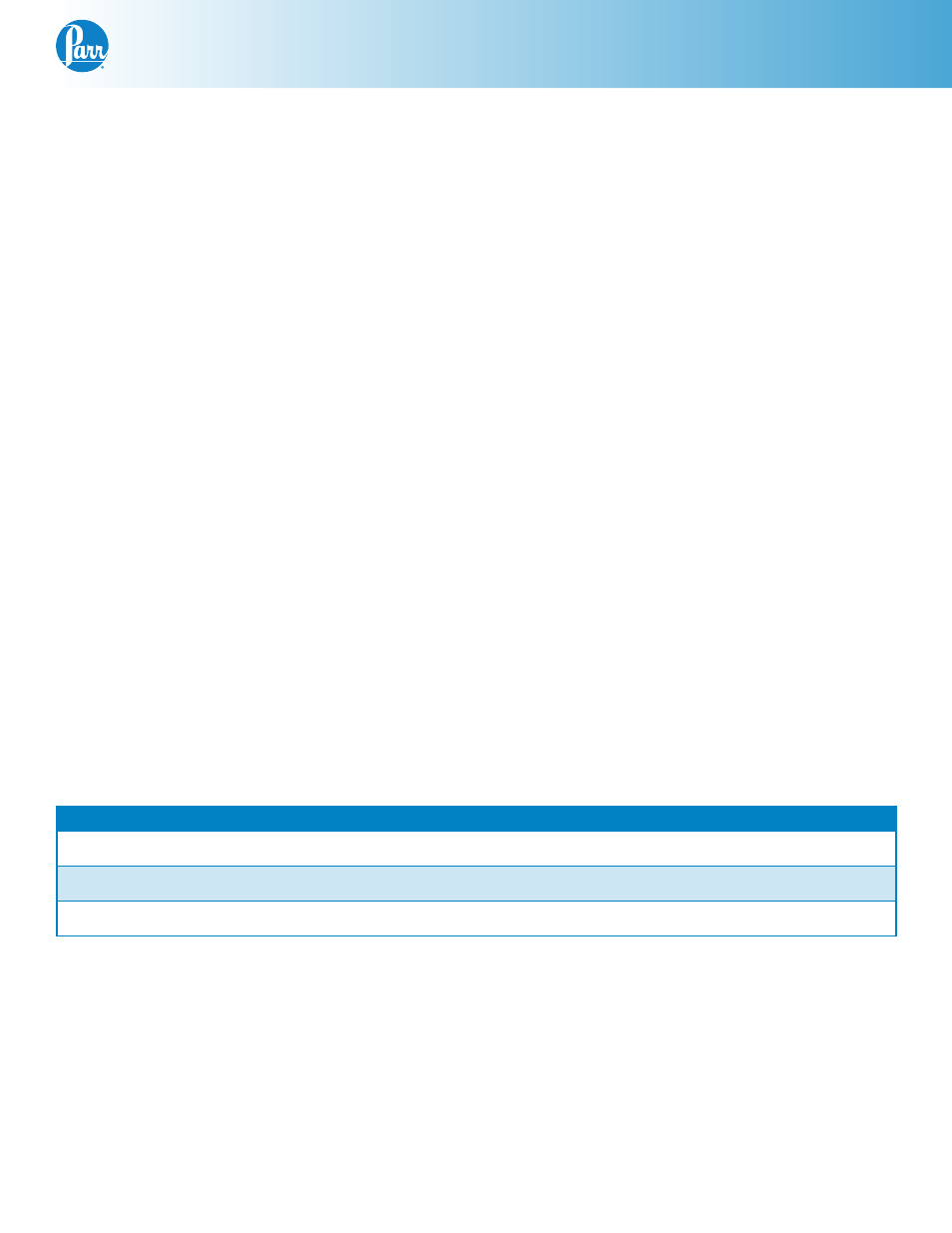

Pressure and Temperature Limits

The working pressure and temperature in these 100 mL thru 600 mL reactors must not exceed the following maximum limits:

Vessel Material

Maximum Pressure

Maximum Temperature

T316SS

3000 psig

350 ºC PTFE Flat Gasket

T316SS

3000 psig

225 ºC FKM O-Ring

T316SS

3000 psig

300 ºC FFKM O-Ring