Other vessel head fittings, Safety rupture disc, Type j thermocouple – Parr Instrument Series 5500 User Manual

Page 11: Pressure gage, Accessories, Liners, Spare parts kit, Compact mini bench top reactors

Compact Mini Bench Top Reactors

w w w . p a r r i n s t . c o m

11

OTHER VESSEL HEAD FITTINGS

Safety Rupture Disc

There is a safety rupture disc attached to the head

which is intended to rupture and release the pres-

sure before it reaches a dangerous level. A metal

tag wired to the safety head identifies the burst

pressure at room temperature for that particular

disc. A similar tag is furnished with each replace-

ment disc. This tag must remain with the apparatus

at all times so that both present and future opera-

tors will be aware of the disc rating. Users should

read the discussion of rupture discs given in the

Operating Instruction No. 231M for a complete

description of the characteristics of rupture discs

and the precautions to be observed when operating

pressure equipment protected by this type of safety

device.

A typical pre-bulged disc can be used to 90% of the

rating on the tag. For additional protection, the user

should install an adequate and safe venting system

for removing any toxic, flammable or volatile ma-

terials which would be released if the rupture disc

should burst. A connector for attaching 3/8" OD

tubing to the discharge port of the rupture disc is

provided for this purpose.

Type J Thermocouple

A Type J Thermocouple in a 1/8" diameter Stainless

steel sheath is installed in each reactor. In reac-

tors made of alloys other than stainless steel, the

stainless thermocouple is installed in a thermowell

made of the same alloy as the vessel. Connect the

thermocouple to the socket on the rear panel of the

temperature controller using the A470E2 extension

wire furnished with the reactor.

Pressure Gage

The pressure gage furnished with this reactor has

a T316 Stainless Steel Bourdon tube. Gages are

furnished in a variety of ranges to meet individual

needs. Typically, the gage and the rupture disc are

furnished as matched ranges. For applications

where a gage is selected with a range under 1000

psi, a relief valve is added and set to protect the

gage. A 1000 psi rupture disc is installed as the fail-

safe vessel protection.

For highly corrosive applications where the vapor

phase might corrode the stainless Bourdon tube,

Parr offers isolator assemblies in a variety of materi-

als. These isolators with their internal piston isolate

the vapors from the gage.

ACCESSORIES

Liners

Glass or PTFE liners can be furnished to fit most

Parr reactors. These liners slide into the cylinder.

Although they will not keep corrosive vapors from

reaching the surfaces of the cylinder and head, they

make it much easier to add and remove liquid reac-

tants, and they give some protection to the cylinder

when working with corrosive solutions. It must be

noted, however, that adding a PTFE liner will slow

the heat transfer rate into the vessel, and it may be

necessary to adjust the temperature control method

to prevent overheating.

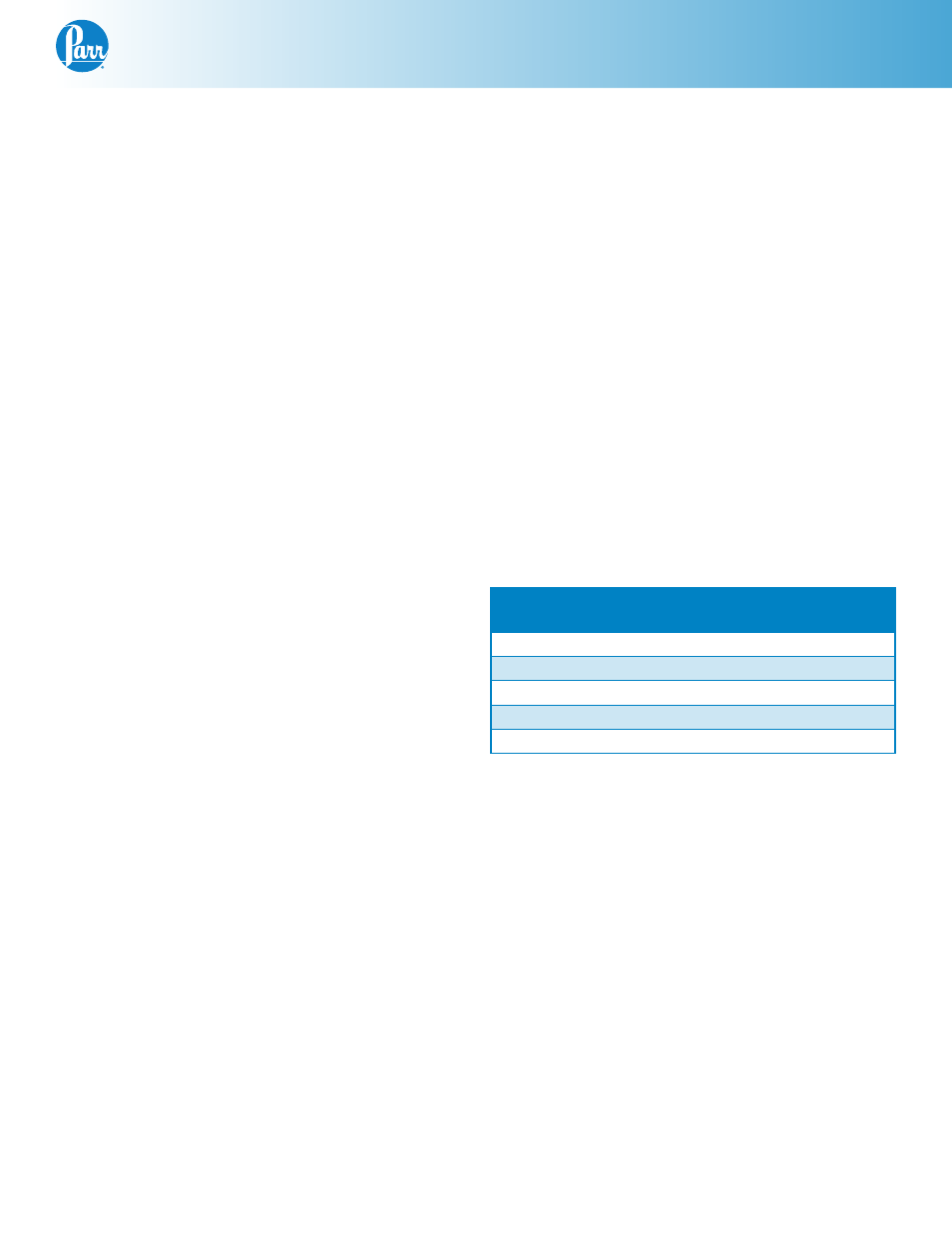

Liner Part Numbers

Fits ID Cylinder

Size

Glass Liner

PTFE Liner

2.06"

100 mL

762HC7

762HC7HA

2.5"

160 mL

762HC8

762HC8HA

2.5”

300 mL

762HC

762HC4HA

2.5"

450 mL

762HC2

762HC5HA

2.5"

600 mL

762HC3

762HC6HA

Spare Parts Kit

Spare parts kits are available for these reactors. The

kits will provide a reserve supply of parts and tools

sufficient to handle most normal replacements and

emergency repairs during a year of heavy usage.

The kits contain small perishable items required for

continuous operation including gaskets, bushings,

rupture discs and seals. They can be ordered from

any Parr Dealer or direct from the Parr Instrument

Company. The order must specify the reactor size

and indicate type of rupture disc, stirrer drive and

whether it has a flat-gasket or O-ring closure. It is

most advantageous to provide the complete vessel

serial number from the head or cylinder. (See Tech-

nical Support section on page 15 for more info).