Accessories, Internal cooling coil, Liners – Parr Instrument Series 4570 User Manual

Page 14: Spare parts kit, Variable speed electric motor

- 14 -

4570 HP/HT Pressure Reactors

Parr Instrument Company

ACCESSORIES

Internal Cooling Coil

A serpentine cooling coil is mounted to the

underside of the head and sealed with a ferrule

and compression nut arrangement.

A slow continuous flow of cold water

through the coil is an effective means for

controlling temperature overshoot, particularly

when operating at temperatures below 150

C.

Alternately, the cooling coil is used to

effectively cool the system at the completion of

a reaction.

An optional solenoid valve package is

available to automate the cooling process.

This package coordinates with the internal coil,

with the water supply and connects to the

temperature control.

If the internal cooling is not required, the

coil may be removed and the alternate plugs

installed.

Liners

Glass (500 °C) or PTFE (250 °C

maximum) liners can be furnished to fit most

Parr reactors. These liners slide into the

cylinder. Although they will not keep

corrosive vapors from reaching the surfaces

of the cylinder and head, they make it much

easier to add and remove liquid reactants,

and they give some protection to the

cylinder when working with corrosive

solutions. It must be noted, however, that

adding a PTFE liner will slow the heat

transfer rate into the vessel, and it may be

necessary to adjust the temperature control

method to prevent overheating.

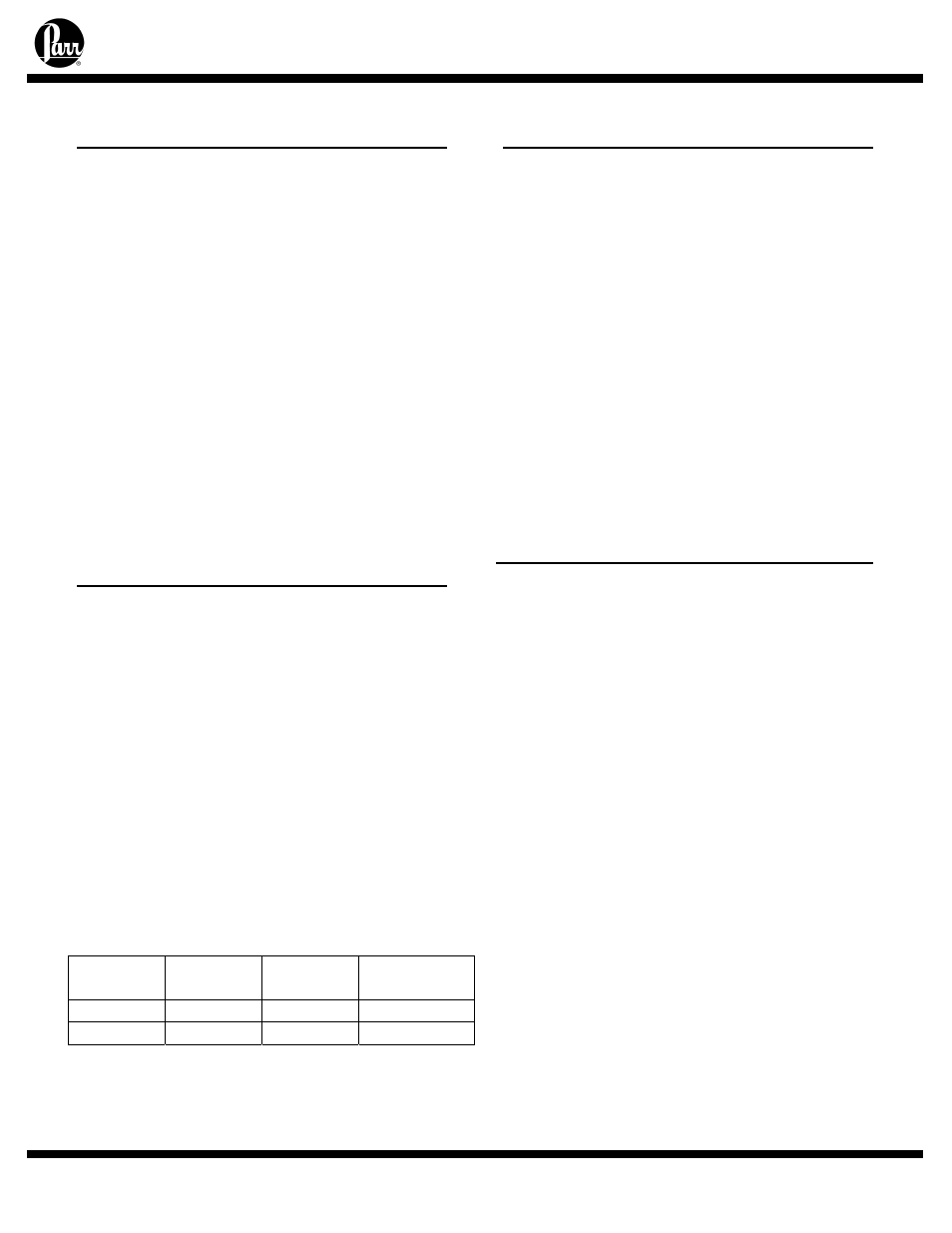

Liner Part Numbers

Fits

ID

Cylinder

Size

Glass

Liner

PTFE

Liner

3.75” 1000

mL

1441HC

1441HCHA

3.75” 1800

mL

1442HC

1442HCHA

Spare Parts Kit

Spare parts kits are available for these

reactors. The kits will provide a reserve

supply of parts and tools sufficient to handle

most normal replacements and emergency

repairs during a year of heavy usage.

The kits contain small perishable items

required for continuous operation including

gaskets, bushings, rupture discs and seals.

They can be ordered from any Parr Dealer

or direct from the Parr Instrument Company.

The order must specify the reactor size and

indicate type of rupture disc, stirrer drive

and, whether it has a flat-gasket or O-ring

closure. It is most advantageous to provide

the complete vessel number from the head

or cylinder.

Variable Speed Electric Motor

Reactors are normally equipped with a

DC variable speed motor supplied and

controlled through the Series 4848

controller. Instructions for connecting and

operating these motors are included in the

controller instruction sheet No. 548M. This

motor is usually installed in a drive system

designed to produce stirring speeds from 0

to 600 rpm. Higher speeds up to 1700 rpm

can be obtained by substituting larger

diameter motor drive pulleys.