Platform performance testing, Dis-assembly, Re-assembly – Nor-Cal RS Series Differentially Pumped Rotary Platforms User Manual

Page 7

7

Call toll free

800-824-4166

or 530-842-4457

•

FAX 530-842-9130

Dis-assembly:

Remove the RS from use and cap pumpout ports. Remove Vernier scale. Remove worm drive gear and motor/fine adjust unit, if mounted.

Take care to note the spacers used in mounting this equipment.

Thoroughly clean all exposed surfaces with alcohol and “LINT FREE” wipes. Move unit to a clean work area. Use a clean hood or laminar

flow work area if possible.

Remove perimeter bolts/screws from the black anodized clamp ring and remove ring.

The two flanges can now be separated. Special care needs to be taken with the bearings. The outer race is split, and bearing will dis-assem-

ble easily. Protect sealing surfaces from mechanical damage at all times.

Remove and clean all interior components. Use alcohol and “LINT FREE” wipes. Inspect actual seal surfaces and seals.

Clean and re-lubricate bearings.

Re-assembly:

Replace components, taking special care to clean sealing surfaces. Install clamp ring and gently tighten ring. IMPORTANT.... Tighten using a

balanced “star” sequence. Blank off and pump on platform (< 1 Torr). Re-tighten clamp ring screws, rotating seal between screw tightening

sequences.

Test unit.

PLATFORM PERFORMANCE TESTING:

1) Install platform per specifications with mass spectrograph leak detector on the UHV volume. Bag check for 30 seconds. No leak

should be observed with a sensitivity of 5 x 10-10 std. cc He/sec.

2) Install platform on leak detector and pump on second stage to between 1 and 5 microns. Transfer 1 atm. of He into the first

pumping stage. A correctly operating platform will display a leak rate of between 1 an 8 x 10-9 std. cc He/sec, depending

on size

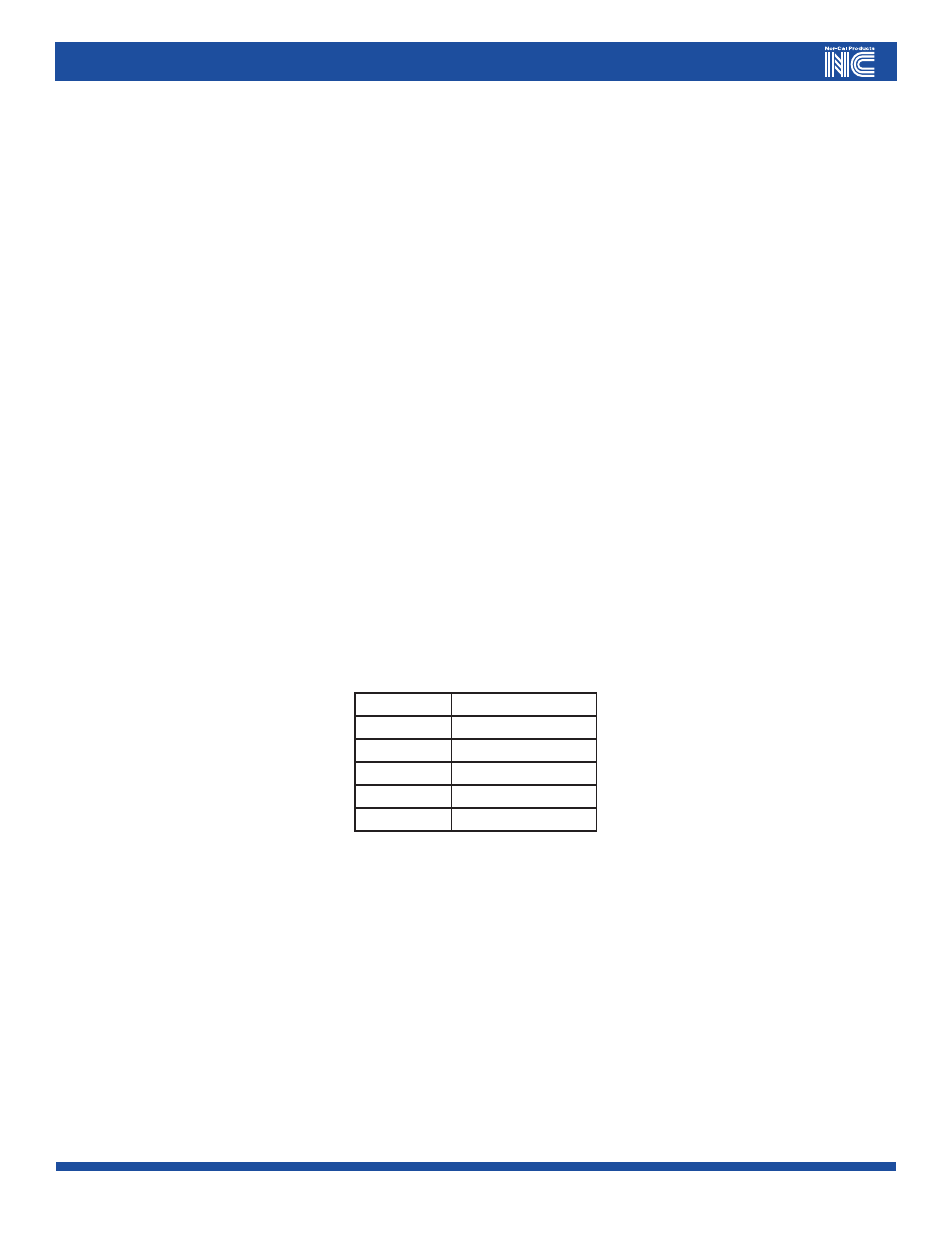

3) The torque required to rotate the platform under vacuum should be less than or equal to the torque values indicated on the

following table:

RS-150

4 ft.-lbs.

RS-250

6 ft.-lbs.

RS-400

6 ft.-lbs.

RS-600

22 ft.-lbs.

RS-800

32 ft.-lbs.

RS-1000

more than 50 ft.-lbs.