Installation, Orientation and load, Fastening/gaskets – Nor-Cal RS Series Differentially Pumped Rotary Platforms User Manual

Page 3: Bolt sizes/lubrication

3

Call toll free

800-824-4166

or 530-842-4457

•

FAX 530-842-9130

INSTALLATION

The RS is shipped clean and ready to install. Remove the protective polyethylene bags.

Prior to shipment, the RS is leak checked. A certificate indicating the leak rate is included with the RS.

Be certain no foreign residue or particles adhere to the device or the sealing flange knife-edges. As a precaution, it is recommended the

flanges be wiped with a lint free cloth prior to installation.

******** WARNING *********

Shipping vibration can loosen screws. The user must check to verify the external screw fasteners have not backed off on the unit.

***********THIS IS IMPORTANT ************

WARNING: NEVER ALLOW THE TWO PUMPING PORTS LOCATED ON THE PERIMETER TO REMAIN UNCOVERED. This device is sensitive

to foreign matter entering the sealing system. The seal effectiveness and useful life are effected by the cleanliness of its environment.

Particles can migrate through the pumping ports, contaminating the chambers, and this can cause seal failure.

At all times, do one of the following:

1) Connect the ports to suitable pumps

2) Cover the ports with the plastic caps provided (always remove during bakeout and replace with materials that will not melt)

3) Cover with clean foil or other suitable material.

ORIENTATION and LOAD

The RS will accommodate up to a 50-lb. load in a vertical orientation. For loads greater than 50 lbs.; or inverted operation; or horizontal

cantilever operation, please consult the factory.

FASTENING/GASKETS

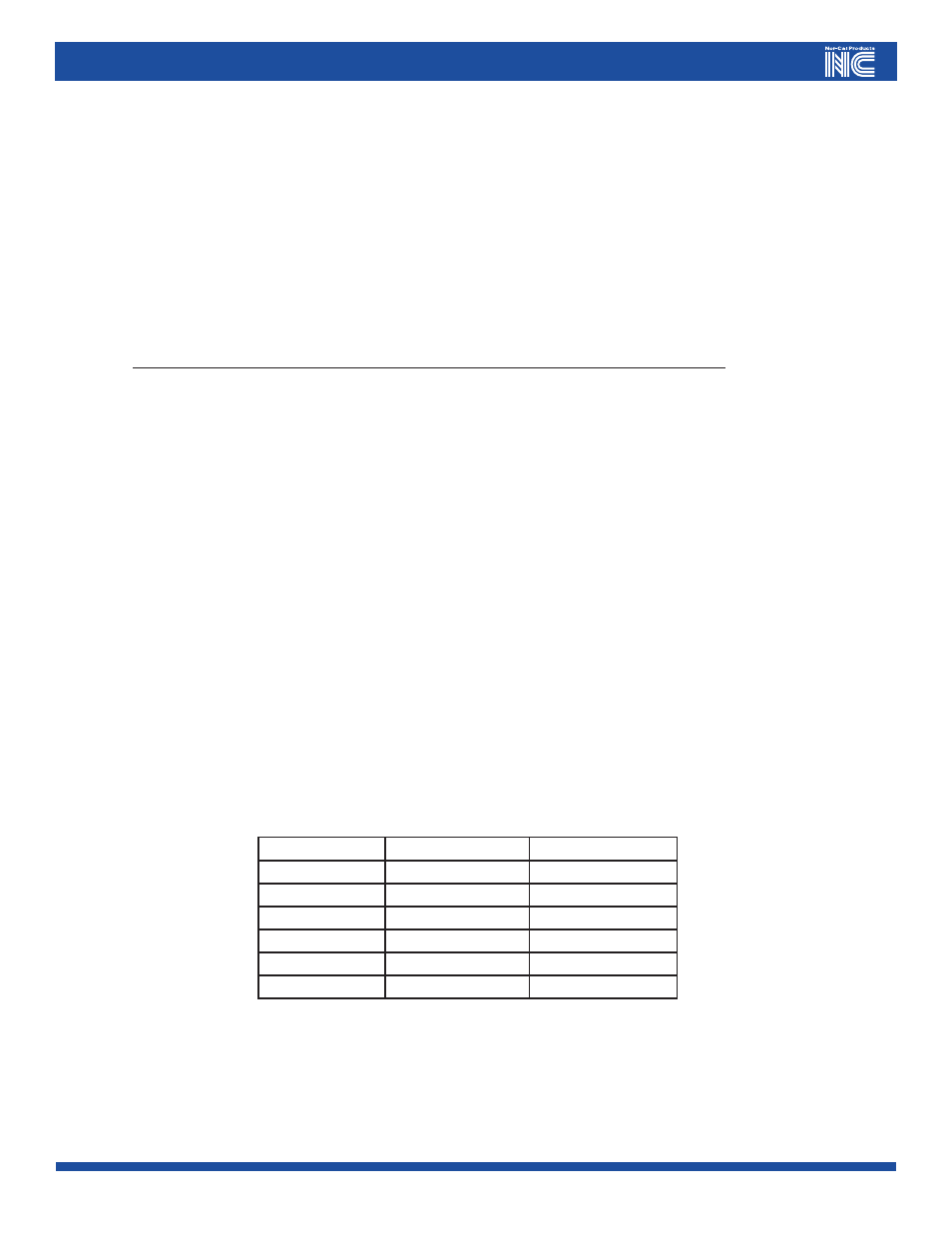

Install the RS on your chamber/manipulator/instrument as you would any other ConFlat flange. Use standard, 0.080” thick, flat copper

gaskets. Use the bolt sizes recommended in the following table for installation. These recommended bolt lengths are for standard thick-

ness ConFlat flanges.

The holes in the RS are blind tapped holes. USING INCORRECT LENGTHS FOR INSTALLATION WILL DAMAGE THE RS ASSEMBLY. The

bolts may be supplied by you, or you may use an RS bolt set available from Thermionics.

Helicoil brand thread inserts are used to improve thread life and performance. They also allow for replacement if thread damage occurs.

Double check that your equipment has standard thickness flanges. The following bolt length tables are based on standard flange

thickness.

BOLT SIZES/LUBRICATION

You may use hex head, socket head or 12 point bolts; they should be used with washers and should be stainless steel. Use an anti-seize

lubricant to minimize the chance of galling the threads.

RS MODEL

BOLT QUANTITY

BOLT SIZE

RS-150

12 ea.

1/4-28 x .75

RS-250

16 ea.

5/16-24 x 1

RS-400

32 ea.

5/16-24 x 1.25

RS-600

40 ea.

5/16-24 x 1.25

RS-800

48 ea.

5/16-24 x 1.5

RS-1000

60 ea.

3/8-24 x 1.5

The instrument/manipulator/chamber to be installed on the RS may now be installed in same manner as detailed above.