Ntellisys, Hrottling, Utterfly – Nor-Cal Intellisys Throttling Butterfly Valve User Manual

Page 10: Alves, 0 - product support

10

10

Visit our Web Site

www.n-c.com

TBV-OP-LIT 01/04

I

NTELLISYS

T

HROTTLING

B

UTTERFLY

V

ALVES

11

Call toll free

800-824-4166

or 530-842-4457

•

FAX 530-842-9130

TBV-OP-LIT 01/04

I

NTELLISYS

T

HROTTLING

B

UTTERFLY

V

ALVES

5.0 - Product Support

Troubleshooting:

The Nor-Cal Products’ TBV control valve is designed for years of maintenance free operation. MTBF has been determined to be in excess

of 2,000,000 operating cycles or 65,000 hours of typical continuous operation. However, some regular inspections and Preventive Maintenance will ensure

that unexpected failures do not occur. Please refer to Table 5.1 for recommendations on TBV-series preventive maintenance and service.

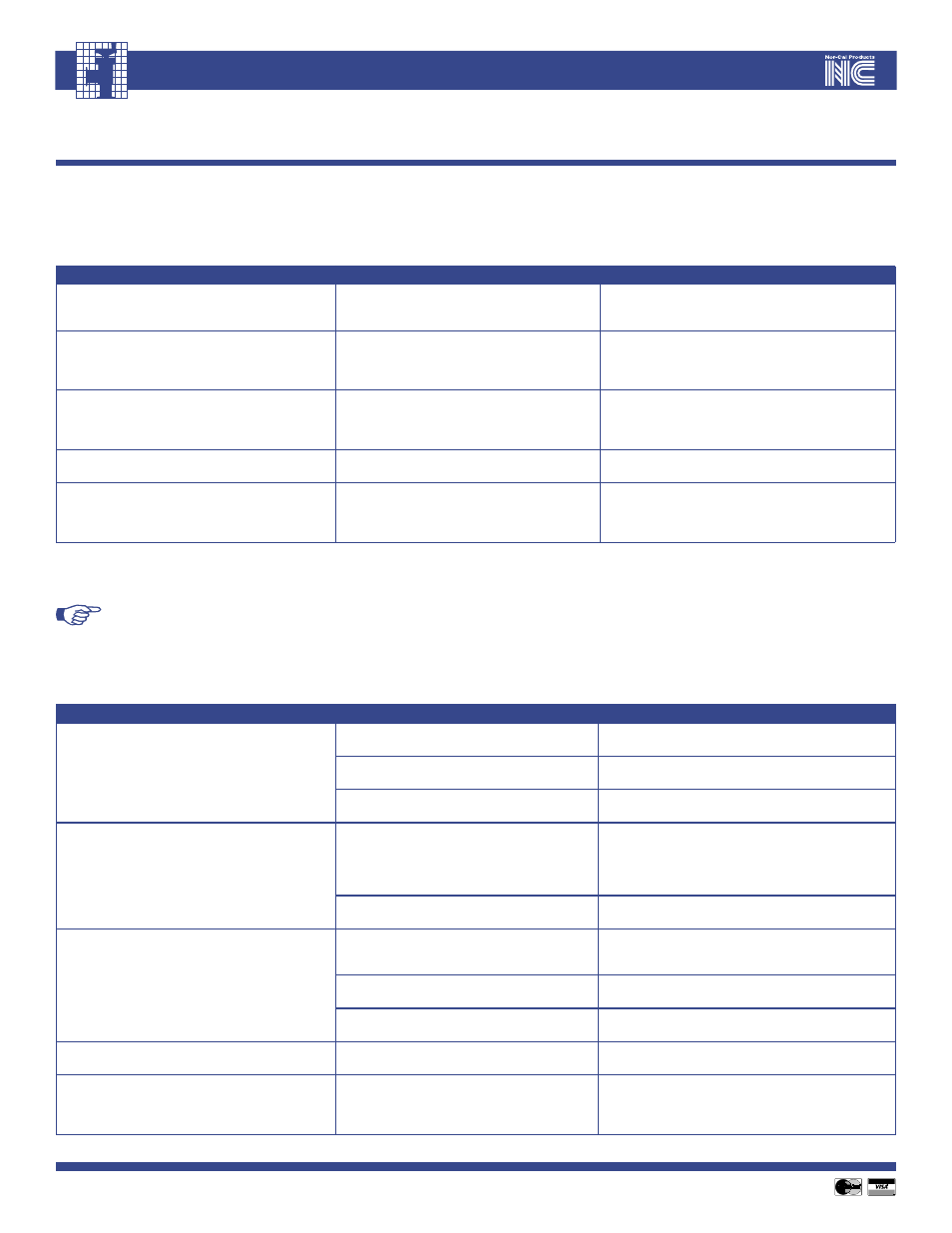

TABLE 5.1 – RECOMMENDED TBV-SERIES PREVENTIVE MAINTENANCE ACTIONS AND INTERVALS

RECOMMENDED ACTION

PURPOSE / WHAT TO LOOK FOR

RECOMMENDED INTERVAL

With controller power OFF

, but valve still installed in

system, manually turn TBV shaft via rear shaft slot or

rotary arm (depending on model).

Feel for areas of high friction or binding, as they may

indicate a build-up of process by-product or valve plate

misalignment due to uneven heating.

Weekly, initially, until a process specific service interval has

been determined for the valve.

Remove TBV control valve from system for visual

inspection.

Look for process build-up. Also, inspect for areas

showing scratches in plate edge or valve inner bore.

The latter can be a sign of plate misalignment, possibly

due to uneven heating.

Monthly, initially, until a process specific service interval has

been determined for the valve.

With controller power OFF

, remove TBV drive unit and

inspect Oldham coupling disk (valve body can remain

installed in vacuum system)

Inspect for Oldham coupling disk wear and fit.

The presence of a whitish powder indicates disk wear.

Also, the disk should fit snugly on each of the two

hubs, and remain on even when upside down.

After 3 months of use, and then every 3 months, until a

process specific service interval has been determined.

Remove TBV control valve from system and

perform leak check.

Determine loss of shaft seal integrity. All new valves

are tested to 1 × 10

-9

atm·scc/sec He

Every 6 months, unless extremely high temperatures or highly

aggressive chemicals are used.

Disassemble valve body to access bearings and O-rings

High vacuum grease used can gradually disappear due

to evaporation or chemical attack. The O-ring seals

can wear or crack due to contamination, chemical

attack or excessive heat.

In heated applications:

after 12 months of continuous use.

In low temperature applications:

after 24 months

of continuous use. Or, whenever a leak is found

via leak detection.

Aside from the Oldham coupling disk and shaft O-rings, there are no user serviceable parts or components in the TBV-series valve. If a problem does occur with

the TBV control valve, please refer to the basic troubleshooting instructions below or contact Nor-Cal Products Intellisys Customer Support at 800-824-4166 to

obtain additional instructions or a Return Materials Authorization number.

NOTE:

A pressure control system issue may not be related to the throttle valve itself. Please also refer

to the Adaptive Pressure Controller Operating Manual for related troubleshooting tips and actions.

Some basic troubleshooting can be done by the user referring to the instructions and suggestions below.

Table 5.2 describes common symptoms and recommended actions.

TABLE 5.2 – POSSIBLE FAILURE MODES AND RECOMMENDED ACTIONS

SYMPTOM

POSSIBLE CAUSES

RECOMMENDED ACTION

The TBV does not appear to turn on or operate.

The TBV is not connected to the controller module

(standard TBV models only)

Check to make sure the controller-to-valve cable is connected

at both ends, using the correct connectors.

The controller-to-valve cable is faulty (standard TBV

models only)

Try another TBV-CRD-XX cable.

The controller module is not on, or is faulty.

Check controller module and refer to appropriate controller

Operating Manual

The TBV appears to operate but pressure- or position

control is inconsistent and poor

The valve plate is jammed or partially

jammed in the valve bore.

Turn off controller power and attempt to move the valve shaft

by hand. If binding is observed, remove valve from system

to determine the root cause. Clean off process residue as

necessary using a non-abrasive method. If plate or valve bore

are damaged, contact Nor-Cal Intellisys Customer Support

The Oldham coupling disk is worn or cracked

Turn off controller power. Remove drive unit from valve.

Replace the Oldham coupling disk as necessary.

A whining or buzzing sound is heard from

the TBV motor drive

The Oldham coupling disk, or possibly hubs, is loose

or worn and a harmonic resonance point has been

excited

Turn off controller power. Remove drive unit from valve.

Replace the Oldham coupling disk as necessary. If problem

persists, contact Nor-Cal Intellisys Customer Support.

The controller motor control coefficients have been

corrupted.

Turn off controller power. Turn back on and allow

initialization sequence to complete

The wrong controller is being used.

Note model and serial number of valve and controller and

contact Nor-Cal Intellisys Customer Support

The motor and valve shaft rotate continuously in one

direction without stopping

The rotor arm used for determination of OPEN and

CLOSED during valve initialization is broken or missing

Contact Nor-Cal Intellisys Customer Support to obtain and

RMA#

The valve has developed a leak to atmosphere along the

valve shaft

O-ring damage and/or loss of vacuum grease can

cause this

The valve plate and shaft need to be removed from the

body so that the O-rings can be replaced and/or re-greased.

Please contact Nor-Cal Intellisys Customer Support to obtain

instructions, or to get an RMA# for valve return.