4 electrical connections, Power connection, Radiometer connection – Kipp&Zonen SHP1 Pyrheliometer User Manual

Page 13: V / ma

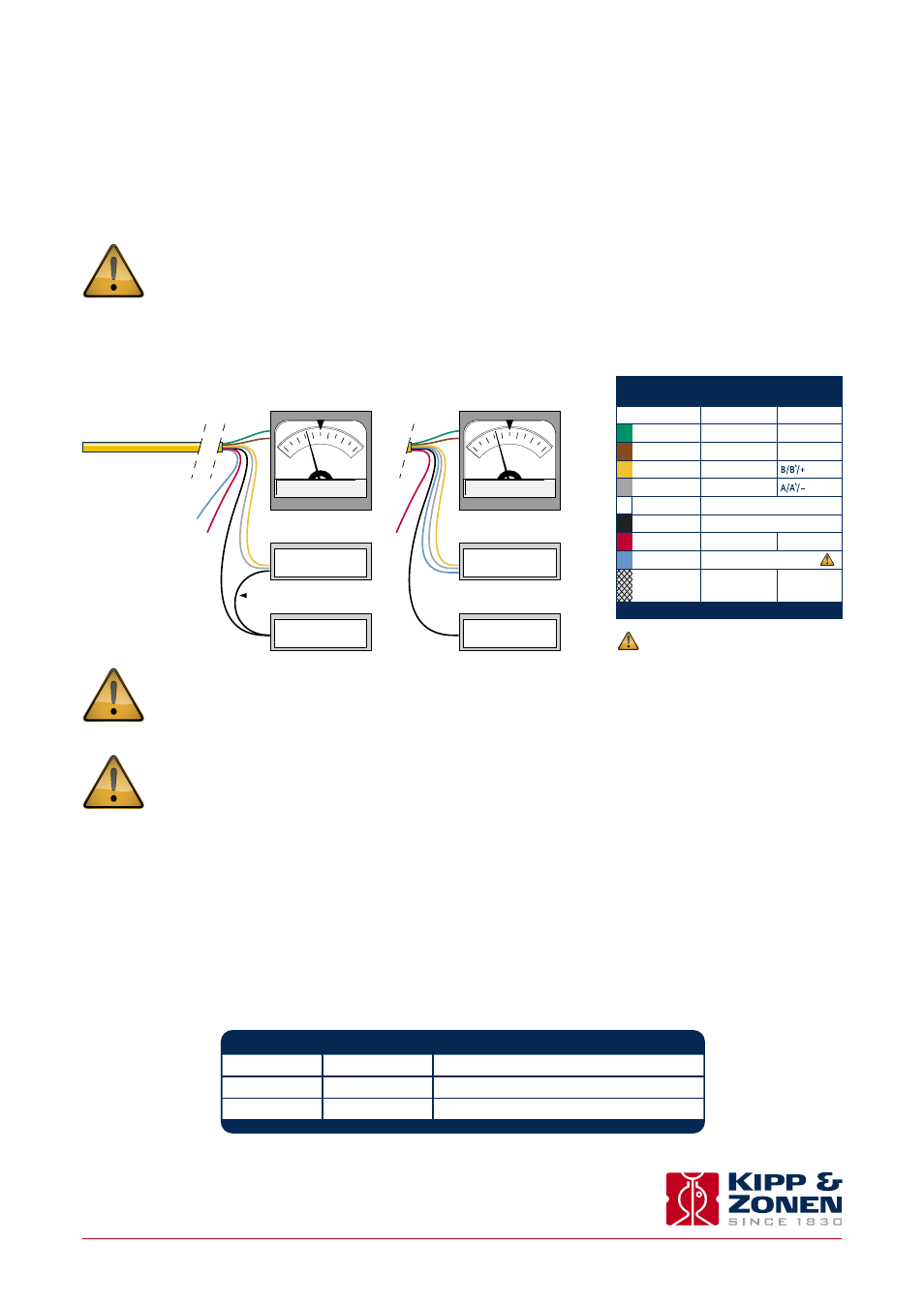

SHP1-V or SHP1-A

SHP1-V or SHP1-A

Radiometer connection

up to

serial number 144999

wire from power supply ground

to Modbus® ground needed

Radiometer connection

starting from

serial numbers 145000

13

Instruction Manual - SHP1 - Smart Pyrheliometer

.

Please follow the instructions in this section carefully for the mechanical and electrical installation of the SHP1 pyrheliometer.

Do not turn on power to the instrument until instructed to do so.

Note

Do not connect the instrument to a computer until instructed to do so.

Note

Do not turn on power to the operating computer until instructed to do so.

2.1 Included with the product

Check the contents of the shipment for completeness (see below) and note whether any damage has occurred during transport. If

there is damage, a claim should be filed with the carrier immediately. In the case of damage and/or the contents are incomplete,

contact your local Kipp & Zonen representative or e-mail the Kipp & Zonen customer and product support department at:

[email protected]

Although a SHP1 pyheliometer is weather-proof and suitable for use in harsh environmental conditions, it has some delicate

mechanical parts. Please keep the original packaging for safe transport of the radiometer to the measurement site, or for use

when returning the radiometer for calibration.

The following items are included with a SHP1 pyrheliometer:

Smart pyrheliometer and rain shield

Cable, pre-wired with 8-pins connector or connector only for customer cable

Calibration certificate

Instruction sheet

2 Dessicant bags

CD with product documentation and software

.

The SHP1 pyrheliometer is delivered with a software programme SmartSensorDemo.exe, This software is supplied on a CD-ROM.

The operating computer must be running on a 32-bit or 64-bit version of Windows™ XP or Windows™ 7. Insert the CD into the

CD/DVD ROM drive of the operating computer and follow the on-screen installation instructions.

Note

Before installing the software it is advised to disconnect all Modbus® devices except for the device that you wish

to configure.

The program is for testing the instrument and setting parameters. Basic data logging and display of data on a PC is also possible.

The software can handle up to 10 SHP pyrheliometers at the same time connected to the same RS-485 to USB converter. This

software is not intended for continuous long-term measurement, which should be done through the RS-485 network controller.

The setup depends on the used RS-485 adapter. An interface that could be used is from B&B, model USOPTL4, that has galvanic

isolation between in- and output. One side holds the USB connector to the PC the other side has a connector for connection of

the wires. This RS-485 adapter is powered from its USB interface.

A power supply for the SHP1 is required, this can be from a 5 to 30 Volt. 12 VDC is advised.

For set-up the following connection to a PC can be used. It is advised to use a RS-485 interface with galvanic isolation between

PC and RS-485.

Care has to be taken when connecting to an ungrounded (portable) PC, especially when also the analogue output is used. The

mains filter inside the PC can generate huge voltage peaks that can exceed the limits of the SHP1 pyrheliometer.

4.1 Set up communication

When the Smart Sensor Demo program is opened there are 3 basic functions available; ‘Overview’, ‘Instrument’ and ‘Chart’.

With the ‘Overview’ tab active the communication parameters can be set as follows:

1. Select the communication port where the RS-485 converter is connected

2. Set the baud rate (19200 is the default setting)

3. Set the number of data bits and parity (8 bits with even parity is the default setting)

4. Set the sampling time (1 poll per second is the default setting)

5. Press the button ‘Discover the first connected device’ (or press ‘Discover all connected devices’ if there is more than one

device connected)

4.2 Change the Modbus® address

With the ‘Overview’ tab active, you have the possibility to change the Modbus® address.

The default Modbus® address of a SHP1 pyrheliometer is 1. Before you can use the instrument in your network you must reconfigure

the address to a unique number. Each Modbus® device connected to a network must have a unique address.

1. Enter the old Modbus® address, this can be found with the button ‘Discover all connected devices’ (for example, enter 1).

2. Enter the new Modbus® address. This must be a unique number (for example, 24).

3. Press the ‘Change Modbus address’ button.

When the address has been changed the SHP1 pyrheliometer will restart itself.

4.3 Instrument data

With the ‘Instrument’ tab active the connected SHP1 pyrheliometer measurements are displayed. If multiple SHP1’s are connect-

ed the display will show alternating values from the different instruments. The large display showing the radiation can be

changed to (Body) Temperature.

The Body Temperature, SHP1 Power Supply Voltage and Time since power on are displayed in the lower part of the screen.

4.4 Chart

With the Chart’ tab active the SHP1 pyrheliometer measurements can be displayed as a graph.

It will show the last 250 measurements of irradiance (‘Radiation’ in W/m²) and/or the pyrheliometer housing temperature

(‘Body Temp’ in °C), as an accumulating graph. Vertical scaling can be set to maximum or automatic.

4.5 Data logging

Under File in Smart Sensor Demo the data logging can be set. The data format options are txt or csv. The csv log file has the

following format:

Together with the Modbus® address and the radiation data the body temperature and the power supply voltage to the SHP1

pyrheliometer are recorded.

At the bottom of the Smart Sensor Demo screen the message ‘The logfile C:\SHPdata\SHP-00.csv is open, press F12 to Append

Data.’ can be shown. With F12 a new data set can be linked to an existing file. Below is an example of a .txt file with linked data

from 2 days.

[11-1-2012 11:08:14]

DATE;TIME;SLAVE;SERIALNR;RADIANCE W/m²;TEMP C;POWER V

2012-01-11;11:08:15;001;00-0005; 708;30.7; 5.0;

2012-01-11;11:08:16;001;00-0005; 708;30.7; 5.0;

2012-01-11;11:08:17;001;00-0005; 708;30.7; 5.0;

[12-1-2012 9:20:17]

DATE;TIME;SLAVE;SERIALNR;RADIANCE W/m²;TEMP C;POWER V

2012-01-12;09:20:30;001;00-0005; 928;22.8; 5.0;

2012-01-12;09:20:37;001;00-0005; 929;22.8; 5.0;

2012-01-12;09:20:38;001;00-0005; 929;22.8; 5.0;

2.2 Tools required

The tool required to mount a SHP1 on a SOLYS 2 or 2AP sun tracker is a 3 mm Allen key. Normally, the drying cartridge for the

SHP1 should be hand-tight, but a 16 mm or 5/8” open-ended wrench / spanner can be used to loosen it.

Check the condition of the desiccant in the SHP1 and replace before installation, if necessary; for example after a long storage

period.

The SHP1 instruction sheet plus the sun tracker manual contain all information to do the installation. When using the digital

output it might be convenient to set the Modbus® address prior to visiting the site, otherwise a computer and RS-485 / USB

converter may be required during installation.

2.3 Location and support

The following steps must be carefully taken for optimal performance of the instrument.

2.3.1 Location

Ideally, the site for the pyrheliometer plus sun tracker should be free from any obstructions to the hemispherical view from the

plane of the detector. If this is not possible, the site should be chosen in such a way that any obstruction over the azimuth range

between earliest sunrise and latest sunset should have an elevation not exceeding 5 ° (the apparent sun diameter is 0.5 °).

Further details for installation of the sun tracker can be found in the manual of the used tracker.

It is evident that the radiometer should be located in such a way that a shadow will not be cast upon it at any time (for example

by masts or ventilation ducts). Note that hot exhaust gas (> 100°C) will produce some radiation in the spectral range of the

radiometer and cause an offset in the measurements. This is important for an accurate measurement of the direct solar radiation.

The radiometer should be readily accessible for cleaning the front window and inspecting the desiccant.

2.3.2 Mounting

The mounting of the SHP1 pyrheliometer is related to the used sun tracker. Therefore we refer to the sun tracker manual for

further instructions on how to mount the SHP1 on the side mounting plate of the sun tracker.

2.3.3 Fitting the connector and cable

Locate the plug correctly in the radiometer socket, it only fits one way, and push it in. Screw the plug locking ring hand-tight.

Over-tightening may damage the waterproof seal. Secure the cable so that it cannot blow in the wind or cause a shadow on the

instrument.

Note

The cable should be arranged with a curve below the instrument so that water drips off, rather than running along the

cable up to the connector.

2.4 Electrical connections

As standard SHP1 pyrheliometers are supplied with a waterproof connector pre-wired to 10 m of high quality yellow cable with 8

wires and a shield covered with a black sleeve. Longer cables are available as options. The colour code of the wires and the

connector pin numbers are shown below and on the instruction sheet.

Special attention is needed to prevent power or ground loops when connecting the SHP1 to multiple readout devices.

Connecting the RS-485 to a grounded circuit and the analogue output to a floating circuit can cause unacceptable

ground loops. This may cause differential voltages outside the SHP1 specifications and will damage the unit. We

recommend using either the analogue or the digital output but not both. The maximum differential between either

of the Modbus® RS-485 lines (yellow and grey) and the power ground / RS-485 common line (black) is 70 VDC.

First connect all wires before plugging into the radiometer

The shield of the cable is connected to the aluminium radiometer housing through the connector body. The shield

at the cable end may be connected to ground at the readout equipment. Lightning can induce high voltages in the

shield but these will be led off at the pyrheliometer and data logger.

Note

Long cables may be used, but the cable resistance must be smaller than 0.1% of the impedance of the readout

equipment for the analogue outputs and may affect the baud rate of the RS-485 digital connection.

2.5 Power connection

The minimum power supply voltage for a SHP1 pyrheliometer is 5 VDC. However, for optimal performance it is advised to use

12 VDC, especially when long cables are used. 5-volt power can only be used in combination with a short cable, maximum 10 m.

It is advised to protect the output of the power supply with a fast blowing fuse of maximum 250 mA rating.

.

Maximum power consumption and input current.

65 mW and 2 mA at the highest input voltage.

63 mW and 12.5 mA at the lowest input voltage.

The maximum inrush current is 200 mA.

The above mW values represent the dissipation within the SHP1-A. For the total power the energy in the load resistor has to

be added.

For supply voltages below 12 Volts or above 20 Volts it is advised to use a load resistor of less than 500 Ω to keep the power

consumption as low as possible.

2.6 Data connection

Connection to a Personal Computer by Universal Serial Bus (USB)

The connection depends on the use of a RS-485 to USB converter.

The converter

must have galvanic isolation between the inputs and outputs to prevent possible damage to the SHP1

digital interface. This is particularly an issue with portable computers (laptops, etc.) in which the power supplies

can generate large voltage spikes.

A suitable converter is the model USOPTL4 from B & B Electronics. One end has the USB connector to the PC the other end has

a connector with screw terminals for the instrument wires. This RS-485 converter is powered from the USB interface, so no

additional power adaptor is necessary.

.

*Note

Switches on the converter should be set for RS-485, 2-wire operation and Echo off.

.

*Note

Switches on the converter should be set for RS-485, 2-wire operation and Echo off.

Connection to a RS-485 Network

The digital interface can be connected to a 2-wire RS-485 network as shown below.

The interface needs also an external power to provide the voltage for the electronics. If the interface is the last device on the

network then a terminator consisting of a 120Ω or 150Ω resistor has to be connected between terminal A/A

'

/- and B/B

'

/+. Never

place the line termination on the derivation cable. It is required to install the pull up and pull down resistors as shown in the

previous figure. The value of these resistors has to be within 650Ω and 850Ω.

2.7 Analogue output connection

The SHP1-V (Volt version) has been factory set to an output of -200 to 2000 W/m². This applies only to the analogue output and

means that an output of 0 Volt corresponds to -200 W/m² (this will never be reached) and 1 Volt corresponds to 2000 W/m².

The digital output range can be modified with Modbus® commands. For the SHP1 the output range can be set to -200 to 4000 W/m²

for 0 to 1 Volt.

Typical power consumption SHP1-V

5 VDC

max. 50 mW

(approx. 10.0 mA)

12 VDC

max. 55 mW

(approx. 4.5 mA)

24 VDC

max. 60 mW

(approx. 2.5 mA)

The range has to start negative in order to show (small) negative readings also the analogue output itself cannot go negative. If

used in atmospheric conditions it is advised to keep the range as factory set.

The same applies for the SHP1-A (current version) that has been factory set to 0 to 1600 W/m² for 4 to 20 mA.

Here negative inputs will make the output go under 4 mA.

2.8 Calculations

2.8.1 Calculation 0 to 1 Volt version

The output is defined from 0 to 1 Volt representing -200 to 2000 W/m².

The irradiance value (

E

solar

) can be simply calculated as shown below in formula 1. The formula assumes the factory default setting

of the analogue output. For calculation of the solar irradiance (global or reflected) the following formula must be applied:

formula 1

E

solar

= Solar radiation

[W/m²]

V = Output of radiometer [Volt]

2.8.2 Calculation 4 to 20 mA version

The output is defined from 4 to 20 mA representing 0 to 1600 W/m².

Negative outputs can cause the output to go slightly below 4 mA.

The irradiance value (

E

solar

) can be simply calculated as shown below in formula 2. The formula assumes the factory default setting

of the analogue output. For calculation of the solar irradiance (global or reflected) the following formula must be applied:

formula 2

E

solar

= Solar radiation

[W/m²]

mA = Output of radiometer [mA]

2.8.3 Recommended cable types

Where cables need to be extended, or the customer prefers to provide their own cables, they should be suitable for outdoor used

and UV resistant.

RADIOMETER CONNECTION

Wire

Function

Connect with

Red

Blue

Housing

Shield

Not connected

None

Modbus® common / Ground

Analogue out

V+/4-20 mA(+)

Analogue ground V-/4-20 mA(-)

Modbus® RS-485

Modbus® RS-485

Power 5 to 30 VDC

(12 V recommended)

Power ground / RS-485 Common

Ground *

White

Black

Yellow

Brown

Green

Grey

5

1

2

8

7

* Connect to ground if radiometer not grounded

The blue wire is not connect with radiometers

with serial number up to 144999

4

6

3

5 to 30 VDC

power supply

Modbus® RS-485

5 to 30 VDC

power supply

Modbus® RS-485

V / mA

0.0

0.2

0.4

0.6

0.8

1.0

V / mA

0.0

0.2

0.4

0.6

0.8

1.0