Hanna Instruments HI 21 Series User Manual

Page 12

23

22

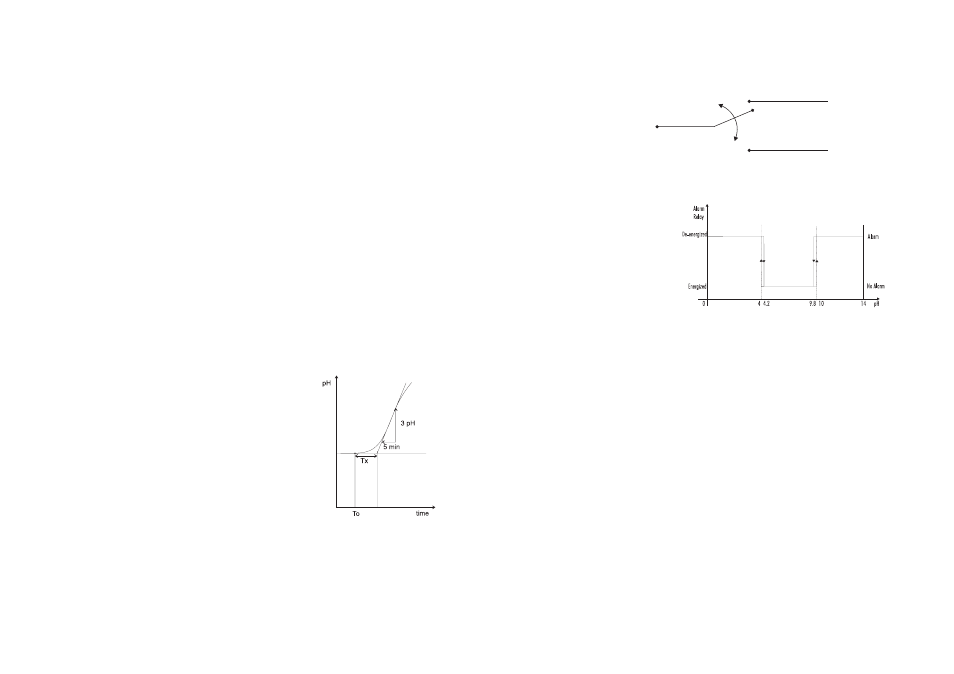

FS•O = NC (Normally Closed)

De-energized Relay

COM

FS•C = NO (Normally Open)

Energized Relay

ALARM RELAY

The alarm relay functions in the following manner:

During alarm condition, the relay is de-energized. When not

in alarm condition, the relay is energized.

Example:

High alarm set at 10 pH

Low alarm set at 4 pH

An hysteresis will eliminate the possibility of continuous se-

quences ‘energizing/de-energizing’ of the alarm relay when

the measured value is close to the alarm setpoint. The hyster-

esis amplitude is 0.2 pH in HI 21 and 30 mV in HI 22.

Moreover the alarm signal is generated only after a user se-

lectable time period (alarm mask) has elapsed since the

controlled value has overtaken one alarm threshold. This

additional feature will avoid fake or temporary alarm condi-

tions.

Note

If the power supply is interrupted, the relay is de-energized as

if in alarm condition to alert the operator.

In addition to the user-selectable alarm relays, all HI 21 and

HI 22 models are equipped with the Fail Safe alarm fea-

ture.

The Fail Safe feature protects the process against critical

errors arising from power interruptions, surges and human

errors. This sophisticated yet easy-to-use system resolves these

predicaments on two fronts: hardware and software. To elimi-

nate problems of blackout and line failure, the alarm function

operates in a “Normally Closed” state and hence alarm is

triggered if the wires are tripped, or when the power is down.

1. Starting from a solution with a pH or mV value different

from the dosed liquid (at least a 3 pH or 150 mV differ-

ence) turn on the dosing device at its maximum capacity

without the controller in the loop (open loop process). Note

the starting time.

2. After some delay the pH or mV starts to vary. After more

delay, the pH or mV will reach a maximum rate of change

(slope). Note the time that this maximum slope occurs and

the pH or mV value at which it occurs. Note the maximum

slope in pH or mV per minute. Turn the system power off.

3. On the chart draw a tangent to the maximum slope point until

intersection with the horizontal line corresponding to the initial

pH or mV value. Read the system time delay Tx on the time axis.

4. The deviation, Ti and Td can be calculated from the following:

• Deviation = Tx * max. slope (pH or mV)

• Ti = Tx / 0.4 (minutes)

• Td = Tx * 0.4 (minutes).

5. Set the above parameters and restart the system with the

controller in the loop. If the response has too much over-

shoot or is oscillating, then the system can be fine-tuned

slightly increasing or decreasing the PID parameters one

at a time.

Example:

the chart recording in the figure

aside was obtained continuously

dosing an alkaline solution to a

weak acid solution in a tank. The

initial settings will be:

Max. slope = 3 pH/5 mins = 0.6

pH/min

Time delay = Tx = approx. 7 mins

Deviation = Tx * 0.6 = 4.2 pH

Ti = Tx / 0.4 = 17.5 mins

Td = Tx * 0.4 = 2.8 mins