5 boiler installation – Glow-worm Micron 50FF User Manual

Page 13

13

2000225227C

Diagram 5.3

7199

TAIL PIPE

TUBING

NUT

RUBBER

WASHER

AIR VENT

RETURN

FLOW

5.1 Unpacking

Open the carton, check the items supplied against the boiler

pack contents list on the carton flap.

5.2 Boiler Preparation

With the boiler still in the bottom tray, remove the casing front

cover. To do this open the controls cover first, then by undoing

the two screws at the bottom and the one at the top, lift the front

cover off, see diagram 5.1.

Place front cover in a safe place on one side until required.

Remove boiler from carton.

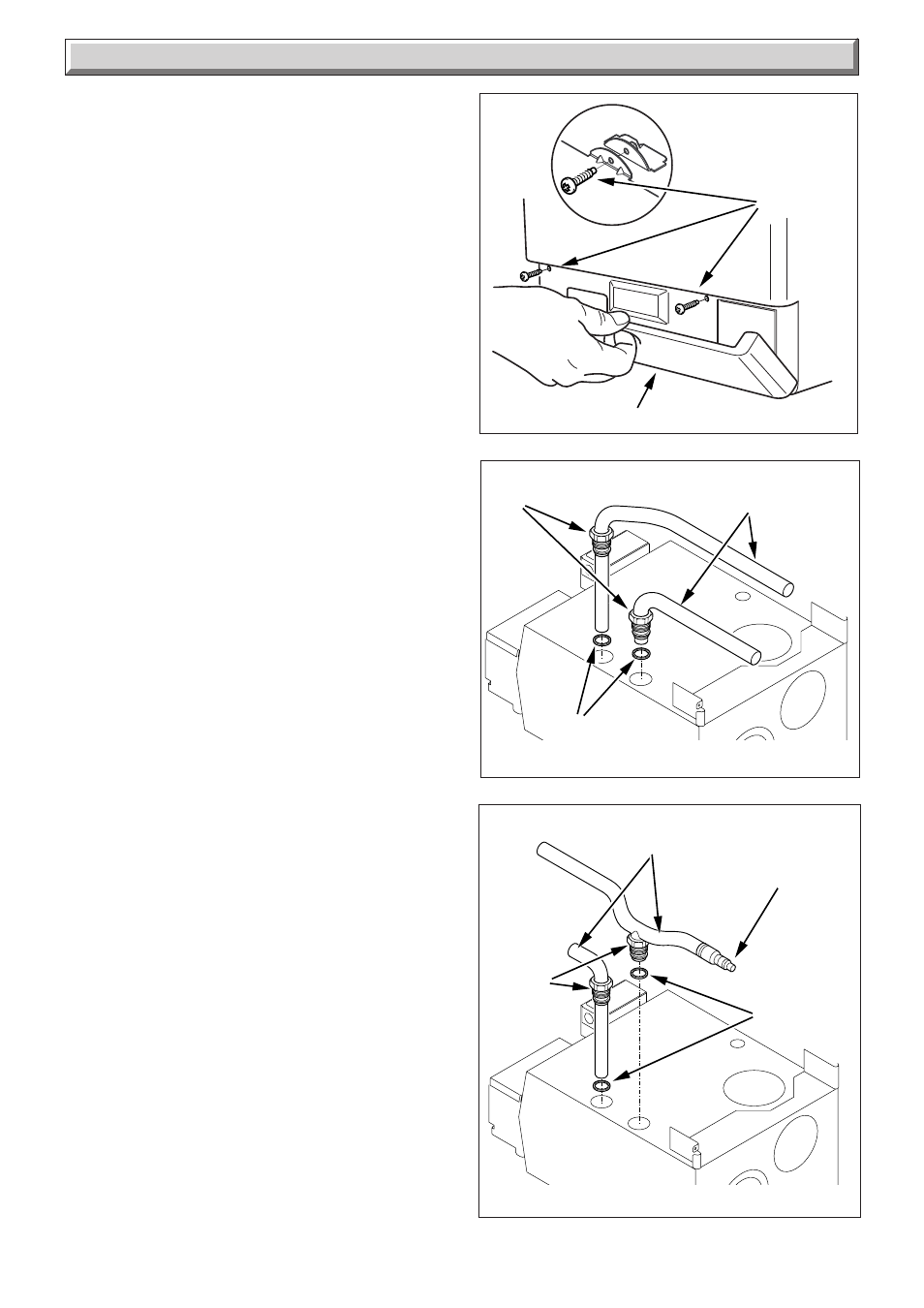

From the fittings pack, slide a tubing nut and washer on to the

return and flow tail pipes which are supplied with the boiler, see

diagram 5.2.

Connect the return and flow tail pipes to the boiler, see diagram

5.2.

Fit suitable compression fittings to the tail pipes.

For pipework entering the boiler from below, an optional flow

pipe incorporating an air vent is available, kit No. 458130. The

return tail pipe supplied with the boiler will need to be cut, see

diagram 5.3.

Note: If the installer wishes to adapt the standard pipework he

may do so, but must incorporate an air vent at the highest point

on the flow pipe, see diagram 5.11.

5.3 Mounting the Boiler

Ensure to fit the blanking plate and gasket on the boiler flue

outlet not being utilised, see diagram 5.6.

If the rear flue outlet is to be utilised for the installation of the flue,

it will be necessary to connect the flue spigot and gasket to the

outlet, using self tapping screws provided, see diagram 5.6.

Note: The spigot would only be fitted to the top flue outlet where

a vertical flue kit or in certain flue bend orientations is

incorporated. Instructions are supplied with these kits.

Lift the boiler into position, hooking over the top mounting

bracket.

Note : Anti-theft screw kits are available, part no's 458113,

458114.

IMPORTANT: Secure lower bracket to wall with screw into

wall plug already prepared.

Note: It will be necessary to move the control box to access the

bracket by slackening its retaining screw and swinging it out on

its hinge, see diagram 5.10.

Where the boiler is located in a restricted place, see diagram

1.3, it may be necessary to remove the control knob to enable

the control box to be fully swung out.

If the top flue outlet is to be utilised, secure the top turret and

gasket or flue spigot and gasket depending on desired flue

orientation in position with the 2 taptite and 2 self tapping

screws provided, see diagram 5.9.

Note: Ensure that the taptite and self-tap screws are positioned

as shown in diagram 5.8 to enable the air deflector to be fitted

correctly.

If fixing to the back of the boiler, i.e. spigot, slide the flue into the

spigot until it engages in the bayonet connection and then twist

anticlockwise to lock, see diagram 4.1.

Make sure the fitting of the flue to the boiler is correct.

The fan assembly may also be removed or slid forward about

halfway out of the boiler, to ease access.

Disconnect the blue and purple electrical connections to the

fan, and the air pressure switch tube connections, see diagram

5.5.

Note: Remove the electrical connections by pulling insulation

boots only.

Remove the securing screw at the front, see diagram 5.5.

The fan assembly may now be slid forward.

5 Boiler Installation

Diagram 5.2

Diagram 5.1

CONTROLS COVER

6769

CASE

SECURING

SCREWS

7200

TAIL PIPE

TUBING

NUT

RUBBER

WASHER

VIEW ON

COVER TOP

RETURN

FLOW