4 flue and appliance preparation – Glow-worm Micron 50FF User Manual

Page 12

12

2000225227C

Carefully drill though air duct pilot hole and secure with self

tapping screw provided in fittings pack, see diagram 4.1.

Seal the joint with the tape provided.

If the flue system requires the addition of flue extension kits,

drill, seal and secure them with the self tapping screw and tape

provided. The completed flue system must not exceed 3

metres, see relevant part of diagram 4.1.

Note: Should any one of the flue sections require cutting to

obtain desired flue system length, cut the 1 metre extension kit

at the end opposite the expanded end.

If the boiler is not to be fitted for some time cover the hole in the

wall.

Note: If a horizontal flue extension is required it must be used

in conjunction with the standard flue, see diagram 4.1.

IMPORTANT: When using the standard flue kit (either rear

outlet or top outlet fixing) or Easyfit, the terminal restrictor

must be fitted. This is not fitted for any other flue type/

arrangement, i.e. extension kits etc.

Note : There are three restictors in the loose items pack,

use the one stamped "D" for the 50FF.

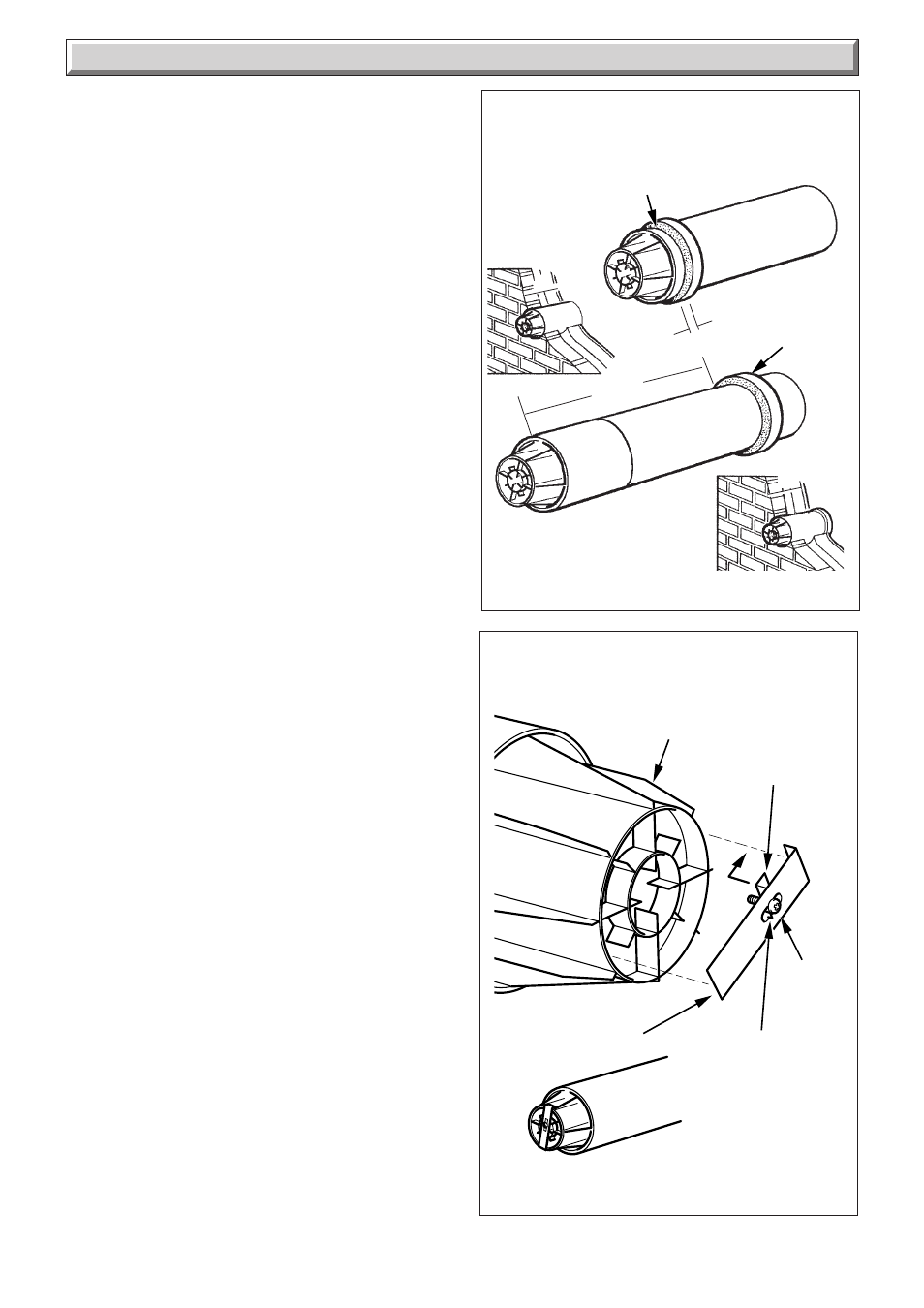

Take the terminal restrictor and position the clamping bracket

making sure the clamping bracket nib protrudes in the slot of the

terminal restrictor and secure with locking screw, but do not

tighten, see diagram 4.6.

Engage the terminal restrictor on the flue terminal by hooking it

over the terminal end and engaging the clamping bracket

behind the inner ring of the terminal securing it by tightening the

locking screw, see diagram 4.6

4.7 Internal Access Flue

If access to the outside wall is not practical, the flue system can

be installed from inside. Use of the optional wall liner kit is

required.

4.8 Rear Flue Fixing

Fit the self adhesive foam seal provided in the flue pack around

the air duct at the position shown in diagram 4.1.

Make sure that the ductings do not slope down towards the

boiler.

Make good around the flue outside after installation of the boiler.

IMPORTANT: If the wall liner kit is used, the self adhesive foam

seal included in the wall liner kit must be used in place of the one

supplied with the flue pack, see diagram 4.5 for position of self

adhesive seal.

4.9 Top, Side Flue Fixing

Make sure that the ductings do not slope down towards the

boiler.

Make good the area around the flue inside and outside after

installation of the boiler.

IMPORTANT: If the wall liner kit is used, the self adhesive foam

seal included in the wall liner kit must be used in place of the one

supplied with the flue pack, see diagram 4.5 for position of self

adhesive seal.

4.10 Flue Positioning

Push the flue assembly into and through the hole such that it is

within the wall, and does not stick out into the room. Do not push

the flue assembly too far into the hole as it has to be pulled back

into the boiler and secured.

4 Flue and Appliance Preparation

Diagram 4.5

FOAM SEAL

FOAM SEAL

WALL THICKNESS-

OVER 300mm

15mm

WALL THICKNESS-

UP TO 300mm

Q-35mm

Q

Q

7102

Diagram 4.6

7323

RESTRICTOR

CLAMPING

BRACKET

CLAMPING

BRACKET NIB

FLUE

TERMINAL

LOCKING

SCREW

TERMINAL RESTRICTOR

SHOWN FITTED

WITH WALL LINER KIT ONLY

STANDARD 510mm REAR AND

STANDARD 570mm TOP FLUE ONLY

EASYFIT 570mm or less

7332