1 general – Glow-worm Hideaway 40CF User Manual

Page 6

6

221807B

1 General

1.4 B.S.I. Certification

This boiler is certificated by B.S.I. for safety and performance.

It is, therefore, important that no alteration is made to the boiler

unless approved, in writing, by Hepworth Heating Ltd.

Any alteration not approved by Hepworth Heating Ltd., could

invalidate the B.S.I. certification, boiler warranty and could also

infringe the statutory requirements.

1.5 Gas Supply

The gas installation shall be in accordance with the current

issue of BS6891.

The supply from the governed meter must be of adequate size

to provide a steady inlet working pressure of 20mbar (8in wg) at

the boiler.

On completion test the gas installation using the pressure drop

method and suitable leak detection fluid, purge in accordance

with the current issue of BS6891.

1.6 Electrical

Warning. This boiler must be earthed.

The electrical installation must be carried out by a competent

person. All external components must be of the approved type

and must be connected in accordance with the current issue of

BS7671 and any local regulations which may apply.

Connection of the boiler and any system controls to the mains

supply should be through a 3A fused double pole isolating

switch, having a minimum double pole contact separation of

3mm, serving only the boiler and system controls.

Heat resistant flexible cable of at least 0.75mm

2

, to the current

issue of BS6500 Table 16 must be used for all connections

within the boiler casing.

1.7 Boiler Location

The boiler must not be installed in a room used or intended to

be used as sleeping accommodation or a room containing a

bath or shower.

This boiler is not suitable for installation out of doors.

The boiler must stand on a level floor, conforming with local

authority requirements and building regulations. The base

temperature is within the requirements of the current issue of

BS5258. The boiler may be stood on a wooden floor but a metal

plate is required to protect plastic tiles and similar floor coverings.

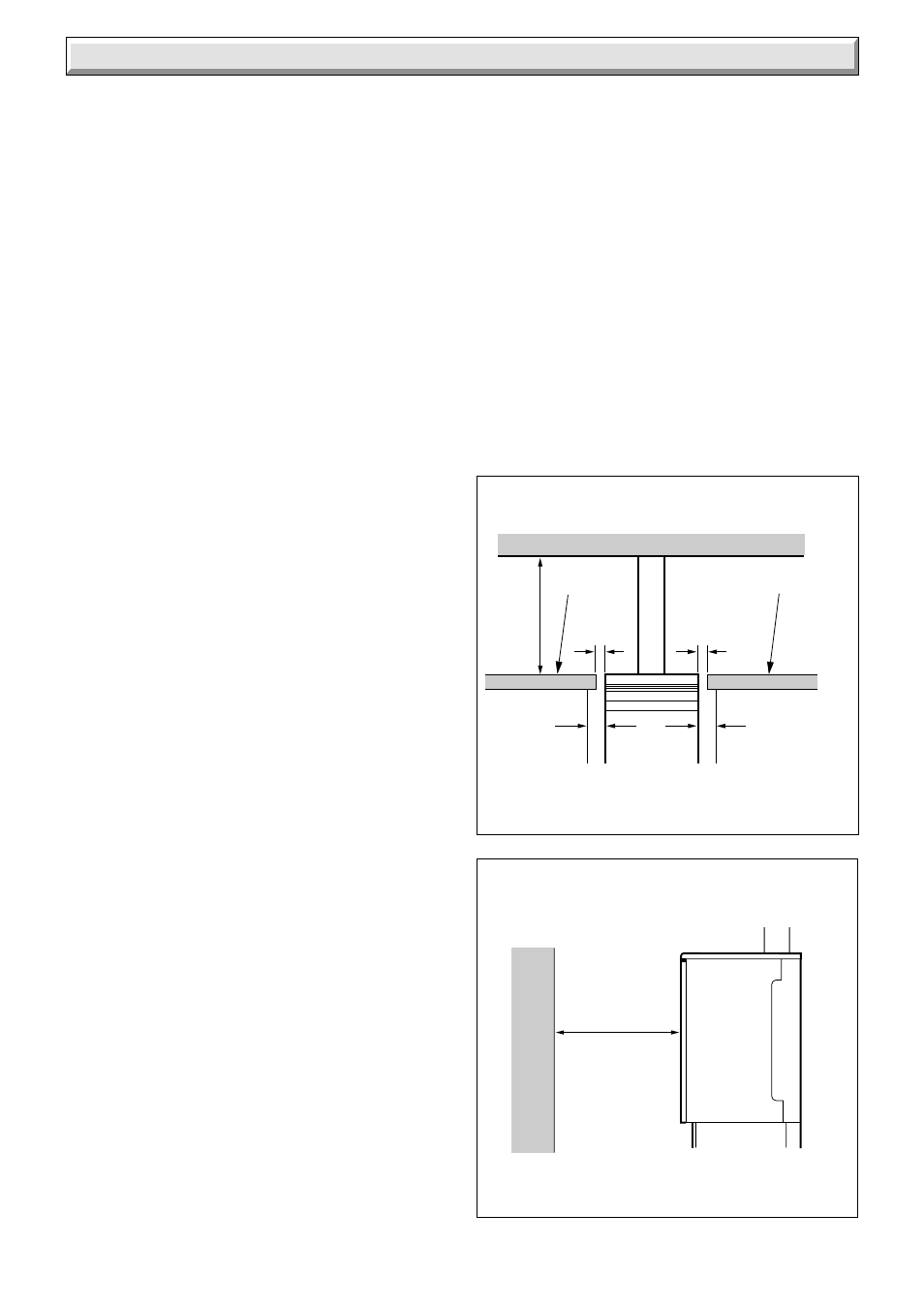

Suitable clearance needs to be available at the sides of the

boiler to ease connection of pipework. The actual clearances

will vary according to site conditions.

When the boiler is to be installed level with work surfaces,

minimum clearances to fixtures, walls and the like should be

provided, see diagram 1.2.

To ease minimum clearances it may be necessary to modify

units or fixtures.

A front access clearance should be provided as shown in

diagram 1.3.

The minimum gap behind the top casing is dimension “G” in

diagram1.1. The boiler can be sited further away from the wall

if required to align with kitchen units.

Combustible wall material must be 25mm (1in) away from flue

components.

A special top casing, part number 424858 can be bought, to

enable boiler casings to be arranged flush with 600mm (23

5

/

8

in)

deep worktops.

Where the installation of the boiler will be in an unusual location,

special procedures may be necessary, the current issue of

BS6798 gives detailed guidance on this aspect.

A compartment used to enclose the boiler must be designed

and constructed specifically for this purpose. An existing

cupboard or compartment modified for the purpose may be

used. Details of essential features of cupboard and compartment

design are given in the current issue of BS6798.

Make sure that nothing will obstruct the side clearances or side

grilles. If installing the boiler in a compartment make sure that

openings and vents are not obstructed.

1.8 Heating System Controls

The heating system should have installed: a programmer and

room thermostat controlling the boiler.

Thermostatic radiator valves may be installed in addition to the

room thermostat.

Note: For further information, see The Building Regulations

1991 - Conservation of fuel and power, 1995 edition - Appendix

G, table 4b.

TOP & SIDE CLEARANCES

Diagram 1.2

Diagram 1.3

FRONT CLEARANCE

530 (21in.)

WALL OR

FIXTURE

0911

BOILER

1020

6

(

1/

4

in.)

6

(

1/

4

in.)

254

(10 in.)

20 (

3/

4

in.)

CUPBOARD

CUPBOARD

BOILER

20 (

3/

4

in.)

WORKTOP

WORKTOP